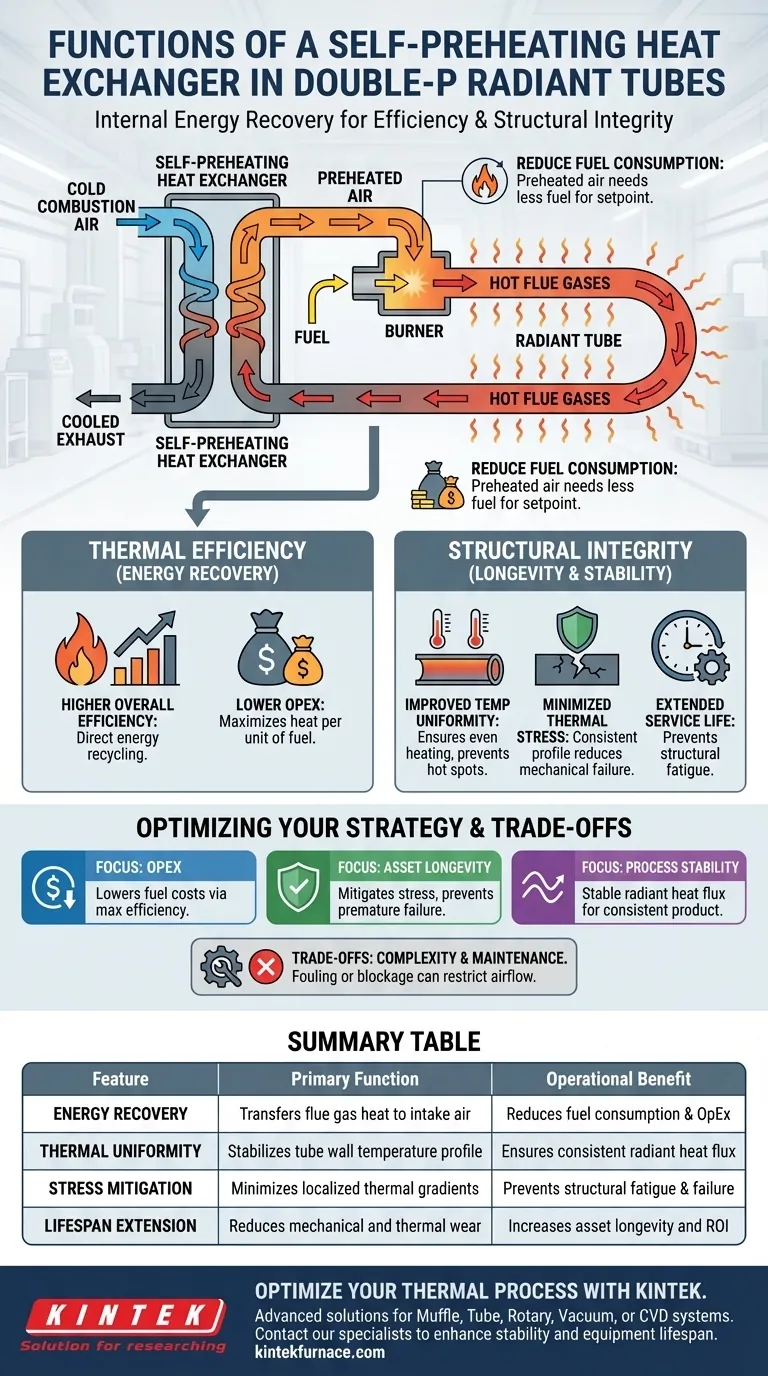

The primary function of a self-preheating heat exchanger within double-P radiant tubes is to act as an internal energy recovery system. It specifically captures waste heat from high-temperature flue gases and transfers it to the incoming combustion air before that air reaches the burner.

By recycling thermal energy that would otherwise be lost, this component significantly increases overall thermal efficiency while simultaneously stabilizing the tube's temperature profile to prevent structural damage.

The Mechanics of Thermal Efficiency

Recovering Waste Energy

The fundamental operation involves heat transfer from exhaust to intake. As high-temperature flue gases exit the system, they pass through the heat exchanger, warming the cold combustion air entering the tube.

Reducing Fuel Consumption

Because the combustion air is preheated, the system requires less fuel to raise the flame temperature to the desired setpoint. This direct recycling of energy creates a higher overall thermal efficiency for the radiant tube system compared to designs without preheating.

Enhancing Structural Integrity

Improving Temperature Uniformity

Beyond simple energy savings, the heat exchanger plays a vital role in how heat is distributed. It enhances the uniformity of the tube wall temperature, ensuring the radiant tube heats evenly rather than developing dangerous hot or cold spots.

Minimizing Thermal Stress

Uneven temperature distribution is a leading cause of mechanical failure in radiant tubes. By ensuring a consistent temperature profile, the heat exchanger minimizes localized thermal stress across the tube's geometry.

Extending Service Life

The reduction in thermal stress directly correlates to durability. By preventing the structural fatigue caused by uneven heating and cooling, the heat exchanger helps to extend the operational lifespan of the double-P radiant tube.

Understanding the Trade-offs

Complexity and Maintenance

While the benefits are clear, introducing a heat exchanger adds mechanical complexity to the tube design. Users must be aware that fouling or blockage within the exchanger can occur over time, potentially restricting airflow and reducing the very efficiency it was designed to create.

Optimizing Your Heating Strategy

If your primary focus is Operational Expenditure (OpEx):

- The self-preheating capability is essential, as it directly lowers fuel costs by maximizing thermal efficiency per unit of heat generated.

If your primary focus is Asset Longevity:

- Prioritize this design to mitigate thermal stress, as the improved temperature uniformity is the key factor in preventing premature tube failure.

If your primary focus is Process Stability:

- The consistent wall temperatures provided by the system ensure a more stable radiant heat flux to your product load.

Integrating a self-preheating heat exchanger transforms a radiant tube from a simple heating element into a sophisticated, self-regulating thermal system.

Summary Table:

| Feature | Primary Function | Operational Benefit |

|---|---|---|

| Energy Recovery | Transfers flue gas heat to intake air | Reduces fuel consumption & OpEx |

| Thermal Uniformity | Stabilizes tube wall temperature profile | Ensures consistent radiant heat flux |

| Stress Mitigation | Minimizes localized thermal gradients | Prevents structural fatigue & failure |

| Lifespan Extension | Reduces mechanical and thermal wear | Increases asset longevity and ROI |

Optimize Your Thermal Process with KINTEK

Don’t let waste heat impact your bottom line. KINTEK’s advanced thermal solutions, backed by expert R&D and world-class manufacturing, provide the precision and durability your laboratory requires. Whether you need Muffle, Tube, Rotary, Vacuum, or CVD systems, our high-temp furnaces are fully customizable to meet your unique operational demands.

Ready to reduce fuel costs and minimize thermal stress in your lab?

Contact our specialists today to discover how our high-efficiency heating technologies can enhance your production stability and equipment lifespan.

Visual Guide

References

- Chien-Cheng Lin, Chien-Hsiung Tsai. Simulation of Staged Combustion Function in Double P-Type Radiant Tubes. DOI: 10.3390/engproc2025092094

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

- Vacuum Heat Treat Sintering and Brazing Furnace

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Molybdenum Disilicide MoSi2 Thermal Heating Elements for Electric Furnace

People Also Ask

- Why are insulation ceramic plugs used inside the alumina furnace tube? Ensure Stable Heating and Prevent Tube Cracking

- What are the technical functions of condensation units and gas collection bags? Optimize Your Reduction Experiments

- Are customization options available for alumina ceramic furnace tubes? Tailor Them for Your Lab's Needs

- What are the technical advantages of using high-purity quartz tubes? Optimize Heat and Purity in Combustion Analysis

- How do a precision hydraulic press and high-strength stainless steel molds facilitate boron carbide green body forming?

- What is the recommended cooling rate for the alumina furnace tube? Prevent Thermal Shock and Extend Tube Life

- How do gravity-fed cast iron ingot molds affect casting quality? Optimize Aluminum Alloy Microstructure

- What is the role of vacuum pressure impregnation equipment in full-cell saturation tests? Ensure Precise ASE Analysis