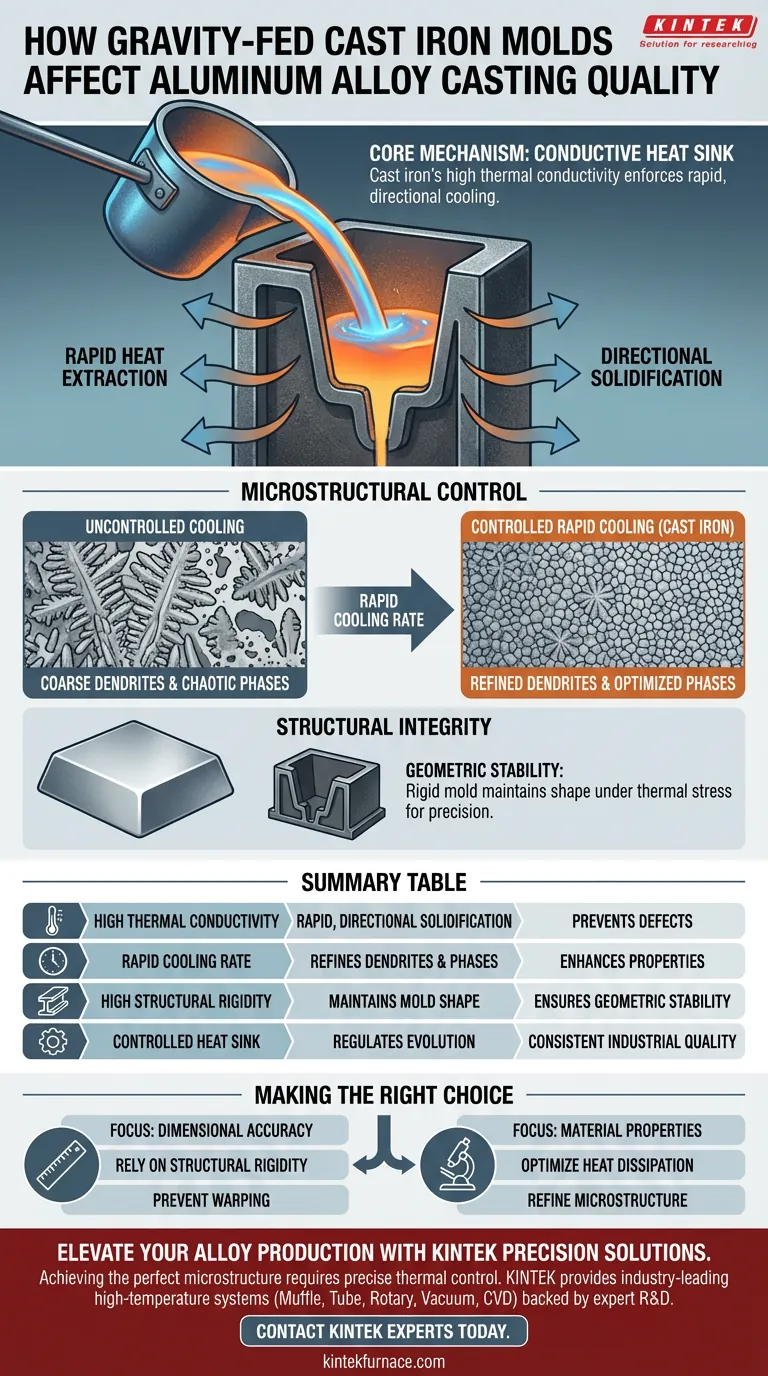

Gravity-fed cast iron molds primarily determine casting quality by acting as a rigid, conductive heat sink that enforces rapid, directional solidification. By controlling the cooling rate, these molds dictate the size of primary dendrites and the distribution of secondary phases, which are the fundamental drivers of the alloy's final material performance.

The core value of a cast iron mold lies in its thermal conductivity. It does not merely shape the metal; it actively regulates the microstructural evolution of the alloy, ensuring both geometric stability and optimized phase distribution through rapid heat extraction.

The Role of Thermal Dynamics

Facilitating Directional Solidification

The primary function of the cast iron mold is to facilitate directional solidification.

Because cast iron possesses high thermal conductivity, it draws heat away from the molten aluminum alloy liquid rapidly. This prevents chaotic cooling patterns and ensures the metal solidifies in a controlled, predictable direction.

The Impact of Cooling Rates

The cooling rate provided by the mold is the most critical variable in the process.

This rate is not a passive byproduct; it is a mechanism that directly dictates the internal structure of the casting. The speed at which the mold extracts heat serves as the defining factor for evaluating the alloy's casting performance.

Microstructural Control

Refining Primary Dendrites

The physical properties of the alloy are heavily influenced by the size of its primary dendrites.

The rapid heat conduction of the cast iron mold constrains the growth of these dendrites. A properly managed cooling rate restricts them from becoming too coarse, leading to a finer, more desirable microstructure.

Distributing Secondary Phases

Beyond the primary structure, the mold influences the characteristics of secondary phases.

The mold's ability to dissipate heat determines how these phases are distributed throughout the ingot. This distribution is essential for ensuring the alloy achieves the specific material properties intended by its composition.

Structural Integrity and Precision

Ensuring Geometric Stability

Industrial applications demand consistency, and cast iron molds provide the necessary structural rigidity.

Unlike softer mold materials, cast iron maintains its shape under thermal stress. This ensures that the final aluminum-based ingot retains stable, accurate geometric dimensions that meet industrial standards.

Critical Considerations for Process Control

The Dependency on Heat Dissipation

While these molds offer significant advantages, they introduce a strict dependency on thermal management.

Because the cooling rate determines both dendrite size and phase distribution, the mold's ability to dissipate heat is the single point of failure for microstructural quality. If the heat conduction is inconsistent, the resulting alloy performance will vary, making mold design and thermal properties the limiting factors in production.

Making the Right Choice for Your Goal

To maximize the quality of your aluminum-based complex concentrated alloys, align your focus with the specific benefits of cast iron molding:

- If your primary focus is Dimensional Accuracy: rely on the structural rigidity of the cast iron to prevent warping and ensure industrial-standard geometric stability.

- If your primary focus is Material Properties: optimize the mold's heat dissipation capabilities to strictly control the cooling rate, thereby refining primary dendrites and secondary phase distribution.

The ultimate success of your casting relies on leveraging the mold not just as a container, but as a precision thermal tool.

Summary Table:

| Feature | Impact on Casting Quality | Benefit to Alloy |

|---|---|---|

| High Thermal Conductivity | Facilitates rapid, directional solidification | Prevents chaotic cooling & grain defects |

| Rapid Cooling Rate | Refines primary dendrite size & phase distribution | Enhances mechanical & material properties |

| High Structural Rigidity | Maintains mold shape under thermal stress | Ensures geometric stability & precision |

| Controlled Heat Sink | Regulates microstructural evolution | Consistent quality for industrial applications |

Elevate Your Alloy Production with KINTEK Precision Solutions

Achieving the perfect microstructure in aluminum-based complex concentrated alloys requires more than just a mold—it requires precise thermal control. KINTEK provides industry-leading laboratory high-temperature systems, including Muffle, Tube, Rotary, Vacuum, and CVD systems, backed by expert R&D and manufacturing.

Whether you need to refine primary dendrites or ensure absolute geometric stability, our customizable furnaces are designed to meet your unique metallurgical needs.

Ready to optimize your casting process? Contact KINTEK experts today to discover how our high-temp solutions can drive your material innovation.

Visual Guide

References

- Compositional Design, Microstructure, and Thermal Processing of Aluminum-Based Complex Concentrated Alloys. DOI: 10.3390/cryst15010088

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

- Molybdenum Disilicide MoSi2 Thermal Heating Elements for Electric Furnace

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Magnesium Extraction and Purification Condensing Tube Furnace

People Also Ask

- What role do graphite molds play in the Spark Plasma Sintering (SPS)? Enhance Alumina Composite Performance

- What role does a planetary ball mill play in Al-Cr-Cu-Fe-Mn-Ni alloy prep? Master Mechanical Alloying Efficiency

- What role does a PTFE-lined high-pressure autoclave play in synthesis of ZnO nanorods? Key Benefits & Growth Factors

- What is the function of BN coating in Y2O3-YAM hot-press sintering? Ensure Purity and Smooth Mold Release

- Why is a laboratory oven utilized during the pre-treatment stage of chicken bone waste pyrolysis?

- What are the functions of silicon nitride ceramic sample holders? Precision for High-Temperature Levitation

- What role does a quartz substrate holder play in MoS2 growth? Optimize Thin Film Deposition with Precision Hardware

- Why is a high vacuum pumping system necessary for carbon nanotube peapods? Achieve Precise Molecular Encapsulation