Spraying Boron Nitride (BN) onto graphite surfaces creates an essential protective interface during the hot-press sintering of Y2O3-YAM ceramics. Its primary functions are to act as a non-reactive mold release agent that prevents the ceramic powder from mechanically adhering to the mold, and to serve as a physical barrier that minimizes carbon diffusion to ensure the chemical purity of the sample.

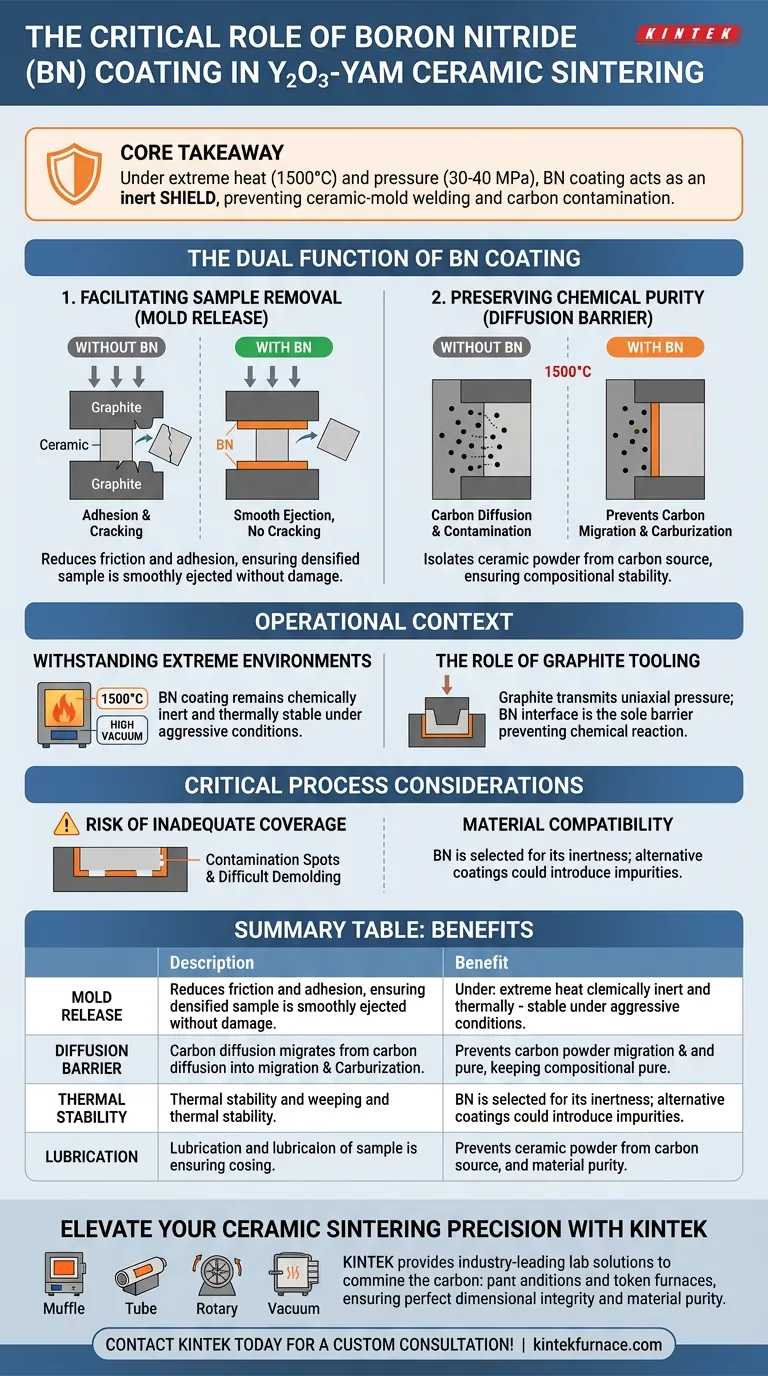

Core Takeaway Under the extreme heat and pressure of sintering, ceramic powders will naturally react with and bond to graphite tooling. A Boron Nitride coating acts as an inert "shield," preventing the ceramic from welding to the mold while simultaneously stopping carbon atoms from contaminating the material's microstructure.

The Dual Function of the BN Coating

Facilitating Sample Removal

The primary surface-level function of the BN coating is to act as a mold release agent.

During hot-press sintering, the Y2O3-YAM powder is subjected to immense mechanical pressure (often between 30 and 40 MPa) to drive densification.

Without a release agent, this pressure combined with high heat would cause the ceramic to stick or adhere effectively to the graphite walls.

The BN coating reduces friction and adhesion, ensuring the densified sample can be smoothly ejected from the mold without cracking the sample or damaging the tooling.

Preserving Chemical Purity

The deeper, more critical function of the coating is acting as a diffusion barrier.

Graphite molds are carbon-rich environments. At sintering temperatures (around 1500°C), carbon atoms become highly mobile and tend to diffuse into adjacent materials.

This diffusion can lead to carburization, where carbon contaminants alter the composition of the Y2O3-YAM ceramic.

By spraying a layer of BN, you effectively isolate the ceramic powder from the carbon source, ensuring compositional stability and preventing contamination.

The Operational Context

Withstanding Extreme Environments

The sintering process for Y2O3-YAM requires aggressive conditions to reach near 100% theoretical density.

The BN coating must maintain its integrity under simultaneous high temperatures (up to 1500°C) and high vacuum environments.

Unlike other potential coatings, Boron Nitride is chemically inert and thermally stable enough to survive this environment without breaking down or reacting with the ceramic powder.

The Role of the Graphite Tooling

Graphite is used for molds because it maintains high structural strength and dimensional stability at temperatures where metals would fail.

Its job is to transmit the uniaxial pressure from the hydraulic system directly to the powder to force particle rearrangement.

Because the graphite is the transmission medium for densification, the BN interface is the only thing preventing a chemical reaction between the driving tool (graphite) and the product (ceramic).

Critical Process Considerations

The Risk of Inadequate Coverage

The effectiveness of the process relies entirely on the uniformity of the BN barrier.

Any gap or thin spot in the sprayed coating creates a direct path for carbon diffusion.

Even localized contact between the powder and graphite can result in surface contamination spots or difficult demolding, potentially ruining the sample.

Material Compatibility

While BN is the standard, it is selected specifically because it resists reaction with fluoride-based or oxide-based powders at high heat.

Using an alternative coating that is not chemically inert could introduce new impurities, defeating the purpose of the barrier.

Making the Right Choice for Your Project

The application of Boron Nitride is not merely a housekeeping step; it is a critical quality control measure.

- If your primary focus is Dimensional Integrity: Ensure the BN layer is uniform to prevent sticking, which eliminates stress fractures during the sample ejection process.

- If your primary focus is Material Purity: View the BN spray as a chemical shield; its thickness and coverage must be sufficient to stop atomic carbon migration at 1500°C.

Ultimately, the BN coating is the invisible guarantor of your ceramic's structural and chemical success.

Summary Table:

| Function | Description | Benefit |

|---|---|---|

| Mold Release | Prevents mechanical adhesion under 30-40 MPa pressure | Easy sample removal without cracks |

| Diffusion Barrier | Blocks carbon atoms from migrating into the ceramic | Maintains high chemical & material purity |

| Thermal Stability | Remains inert at temperatures up to 1500°C | Protects integrity in extreme environments |

| Lubrication | Reduces friction between powder and graphite walls | Extends the lifespan of expensive tooling |

Elevate Your Ceramic Sintering Precision

Achieving 100% theoretical density requires more than just high temperatures—it demands the right environment. KINTEK provides industry-leading lab solutions, including Muffle, Tube, Rotary, Vacuum, and CVD systems, all designed to handle the rigorous demands of advanced material science.

Backed by expert R&D and manufacturing, our high-temp furnaces are fully customizable to your unique sintering requirements, ensuring you achieve perfect dimensional integrity and material purity every time.

Ready to optimize your lab's performance? Contact KINTEK today for a custom consultation!

Visual Guide

References

- Ho Jin, Young‐Jo Park. Microstructural characterization and inductively coupled plasma-reactive ion etching resistance of Y2O3–Y4Al2O9 composite under CF4/Ar/O2 mixed gas conditions. DOI: 10.1038/s41598-024-57697-5

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- Vacuum Dental Porcelain Sintering Furnace for Dental Laboratories

People Also Ask

- Why is a precise gas flow control and supply system necessary during the thermochemical conversion of rice husk biochar?

- Why are laboratory vacuum pumps and pressure gauges essential for aluminum foams? Ensure High-Quality Sintering Results

- What processes can a circulating water vacuum pump provide negative pressure conditions for? Essential Lab Techniques Explained

- What is the primary function of the alumina crucible set in the synthesis of Eu5.08-xSrxAl3Sb6? Expert Analysis

- What is the importance of the quartz boat in BPEA crystal growth? Essential for Purity and Performance

- How does an Aluminum Oxide Crucible ensure MXene purity? Key Role of LSS Etching Protection

- What is the primary function of the vacuum pump system in the magnesium powder evaporation process? Ensure High Purity & Efficiency

- Why is a Zirconia (ZrO2) oxygen sensor used for CaO-Al2O3-VOx slag research? Achieve Precise Redox Control