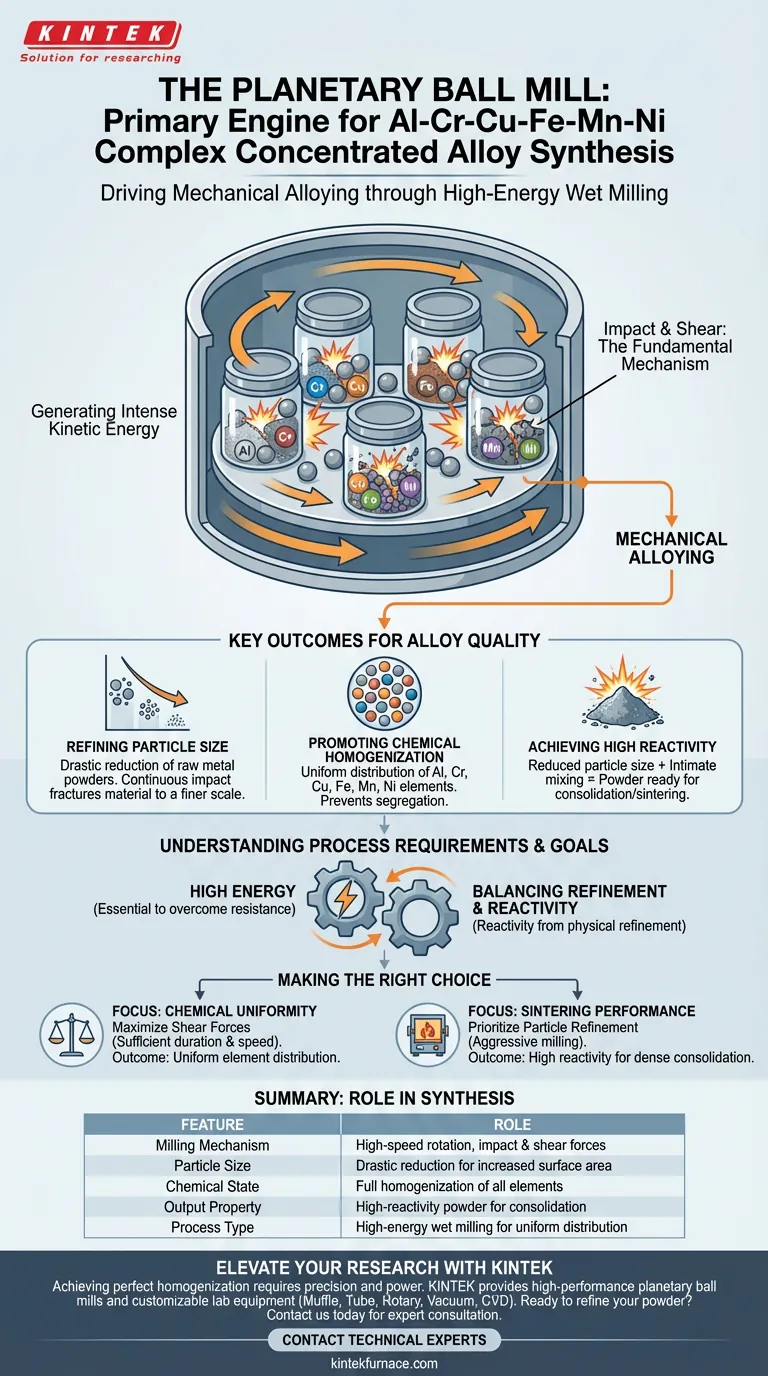

In the synthesis of Al-Cr-Cu-Fe-Mn-Ni alloys, the planetary ball mill acts as the primary engine for mechanical alloying. It utilizes high-speed rotation to generate intense kinetic energy, subjecting the raw materials to significant impact and shear forces. This process, often conducted as high-energy wet milling, is essential for physically facilitating the combination of these diverse metal components into a unified material.

The mill’s high-energy environment drives two essential outcomes: the drastic reduction of particle size and the chemical homogenization of the alloy. This results in a mixed powder with high reactivity, which is critical for successful downstream processing.

The Mechanism of Action

Generating Kinetic Energy

The planetary ball mill operates through high-speed rotation. This movement creates a centrifugal force that accelerates the grinding media (balls) and the powder mixture within the milling jar.

The Role of Impact and Shear

As the mill rotates, the grinding media collides with the powder. This generates high-impact forces that fracture the material and shear forces that tear it apart. These forces are the fundamental mechanism behind mechanical alloying.

Key Outcomes for Alloy Quality

Refining Particle Size

One of the primary functions of this process is the refinement of the average particle size. The continuous impact fractures the raw metal powders, reducing them to a much finer scale than the starting material.

Promoting Chemical Homogenization

Beyond simple size reduction, the mill promotes a high degree of chemical homogenization. The intense mixing ensures that the Al, Cr, Cu, Fe, Mn, and Ni elements are uniformly distributed, preventing segregation within the alloy.

Achieving High Reactivity

The combination of reduced particle size and intimate mixing results in a powder with high reactivity. This state is often necessary to facilitate subsequent consolidation or sintering processes effectively.

Understanding the Process Requirements

The Necessity of High Energy

It is important to recognize that achieving a true complex concentrated alloy requires significant energy input. The "high-speed" and "high-energy" nature of the wet milling process described is not optional; it is required to overcome the physical resistance of the raw metals to alloying.

Balancing Refinement and Reactivity

The goal is to produce a "mixed powder with high reactivity." However, this reactivity is a direct result of the physical refinement. The process relies on the aggressive nature of the milling forces to alter the powder's state effectively.

Making the Right Choice for Your Goal

When configuring your milling process for Al-Cr-Cu-Fe-Mn-Ni alloys, consider your specific targets regarding the powder's final state.

- If your primary focus is Chemical Uniformity: Ensure the milling duration and speed are sufficient to utilize shear forces for maximum homogenization of the six distinct elements.

- If your primary focus is Sintering Performance: Prioritize the refinement of particle size to achieve the high reactivity necessary for dense consolidation.

The planetary ball mill is not just a mixer; it is a high-energy reactor that defines the fundamental characteristics of your final alloy powder.

Summary Table:

| Feature | Role in Al-Cr-Cu-Fe-Mn-Ni Synthesis |

|---|---|

| Milling Mechanism | High-speed rotation generating impact & shear forces |

| Particle Size | Drastic reduction for increased surface area |

| Chemical State | Full homogenization of Al, Cr, Cu, Fe, Mn, and Ni elements |

| Output Property | High-reactivity powder ready for sintering/consolidation |

| Process Type | High-energy wet milling for uniform distribution |

Elevate Your Material Research with KINTEK

Achieving the perfect chemical homogenization for complex concentrated alloys like Al-Cr-Cu-Fe-Mn-Ni requires precision and power. KINTEK provides high-performance planetary ball mills designed to deliver the extreme kinetic energy necessary for successful mechanical alloying.

Backed by expert R&D and manufacturing, we offer a comprehensive range of lab equipment including Muffle, Tube, Rotary, Vacuum, and CVD systems, all customizable to your specific research requirements.

Ready to refine your powder reactivity and sintering performance? Contact us today to consult with our technical experts and find the ideal high-temperature furnace or milling solution for your laboratory.

Visual Guide

References

- Tailoring Mechanical Properties of Al-Cr-Cu-Fe-Mn-Ni Complex Concentrated Alloys Prepared Using Pressureless Sintering. DOI: 10.3390/ma18174068

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- Vacuum Heat Treat Sintering and Brazing Furnace

- Laboratory Muffle Oven Furnace with Bottom Lifting

People Also Ask

- What is the maximum temperature limit for a standard water circulating vacuum pump and what can it reach with special configuration? Discover High-Temp Solutions

- Why is a precision constant temperature drying oven required for BZT ceramic powders? Ensure Perfect Powder Quality

- What are the key characteristics of the circulating water multifunctional vacuum pump? Discover Clean, Oil-Free Lab Solutions

- What role do a laboratory pressure machine and a steel die-set play in the preparation of Mn2AlB2 compacts?

- What considerations lead to the selection of a corundum crucible for CVD sulfurization? Ensure Peak Sample Purity

- Why are high-purity crucibles and sealed reaction environments necessary for NaRu2O4 growth? Ensure Crystal Integrity

- What is the purpose of using a PID controller to drive a heating furnace? Master Thermal Kinetics Precision

- Why is a laboratory vacuum drying oven utilized for recovered carbon black? Preserve rCB Integrity and Pore Structure