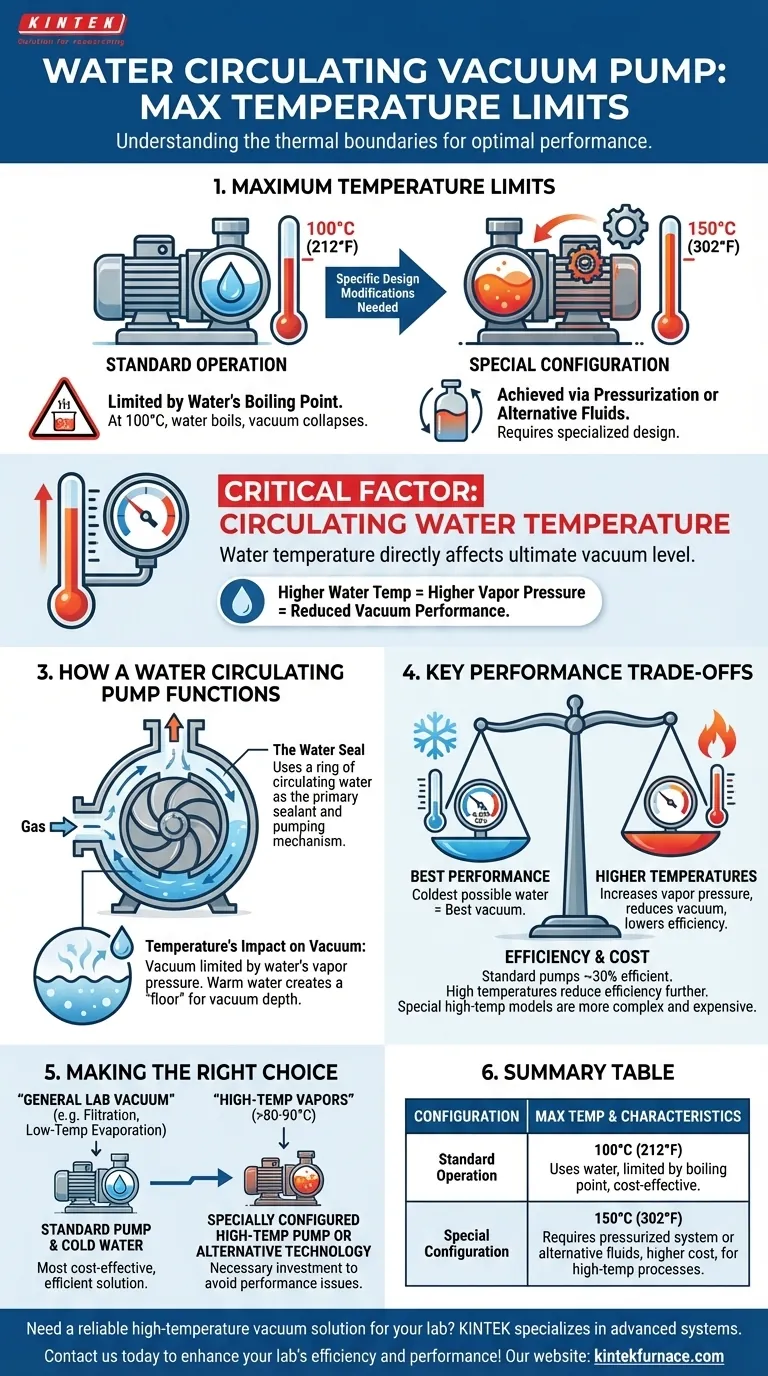

In standard operation, a water circulating vacuum pump has a maximum fluid temperature limit of 100°C (212°F). However, models with special configurations can be engineered to handle fluids up to 150°C (302°F). This higher limit is not a standard feature and requires specific design modifications to achieve.

The temperature of the circulating water is the single most critical factor affecting the pump's ultimate vacuum level. As water temperature increases, its vapor pressure rises, which directly counteracts the vacuum being generated and limits the pump's performance.

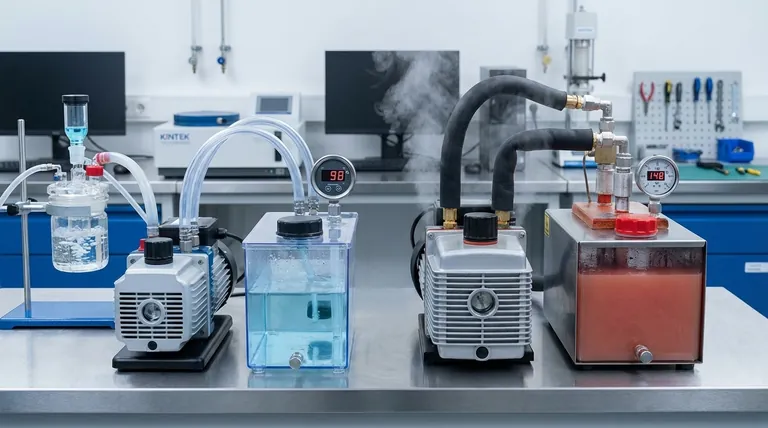

How a Water Circulating Pump Functions

A water circulating vacuum pump, also known as a liquid ring pump, is valued for its simplicity and robustness. Understanding its core mechanism is key to grasping its temperature limitations.

The Role of the Water Seal

These pumps use a ring of circulating water as their primary sealant and pumping mechanism. An impeller spins within the pump casing, throwing the water outwards by centrifugal force to form a stable, liquid ring.

This ring creates a series of sealed chambers between the impeller vanes. As the impeller rotates, these chambers expand, drawing in gas from the inlet port, and then contract, compressing and expelling the gas through the outlet.

Temperature's Impact on Vacuum

The effectiveness of this process is governed by the vapor pressure of the water itself. Every liquid exerts a certain pressure as it evaporates, and this pressure increases exponentially with temperature.

Because the vacuum is being created in direct contact with the water, the ultimate vacuum the pump can achieve can never be lower than the water's current vapor pressure. Warm water has a high vapor pressure, creating a "floor" that limits how deep the vacuum can go.

Understanding the Temperature Limits

The stated temperature limits are not arbitrary; they are based on the physical properties of water and the mechanical integrity of the pump.

The Standard 100°C Limit

The 100°C limit for standard pumps corresponds directly to the boiling point of water at standard atmospheric pressure.

Operating near or above this temperature causes the water in the ring to boil. This turns the stable liquid seal into a chaotic mix of water and steam, causing the vacuum to collapse entirely.

Achieving 150°C with Special Configurations

Reaching 150°C requires moving beyond water's normal physical limitations. This is typically achieved in one of two ways:

- Pressurizing the System: By operating the entire system under pressure, the boiling point of the water can be raised above 100°C, allowing it to remain in a liquid state at higher temperatures.

- Using an Alternative Fluid: The pump can be configured to use a specialized thermal fluid or oil with a much higher boiling point and low vapor pressure as the working liquid instead of water.

These are significant design modifications, not simple adjustments, and require a pump built specifically for such high-temperature service.

Key Performance Trade-offs

Choosing and operating a water circulating pump involves balancing temperature with performance and cost.

Performance vs. Temperature

This is the most critical trade-off. For the best possible vacuum (e.g., approaching the typical maximum of -0.098 MPa or 20 mbar), the circulating water must be kept as cold as possible.

Even well below boiling, every degree increase in water temperature raises the vapor pressure and reduces the pump's maximum achievable vacuum.

Efficiency and Energy Use

These pumps are generally not highly efficient, with standard models operating around 30% efficiency. Higher water temperatures can further reduce overall efficiency as more energy is lost to phase change and turbulence.

Cost and Complexity

A standard water vacuum pump is a cost-effective solution for many applications. However, a specially configured high-temperature model is a more complex and significantly more expensive piece of equipment due to its specialized materials, seals, and potential need for a pressurized system.

Making the Right Choice for Your Application

Your process requirements directly dictate the appropriate pump configuration.

- If your primary focus is general lab vacuum for tasks like filtration or low-temperature evaporation: A standard pump operating with cold tap water is the most cost-effective and efficient solution.

- If your primary focus is pulling a vacuum on processes involving high-temperature vapors (above 80-90°C): You must invest in a specially configured high-temperature pump or consider an alternative technology, such as a dry diaphragm pump, to avoid performance issues.

Understanding these thermal limitations is fundamental to selecting the right pump and ensuring reliable, efficient vacuum performance for your work.

Summary Table:

| Configuration | Max Temperature Limit | Key Characteristics |

|---|---|---|

| Standard Operation | 100°C (212°F) | Uses water, limited by boiling point, cost-effective for general lab use |

| Special Configuration | 150°C (302°F) | Requires pressurized system or alternative fluids, higher cost, for high-temp processes |

Need a reliable high-temperature vacuum solution for your lab? KINTEK specializes in advanced furnace systems like Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. With our strong R&D and in-house manufacturing, we offer deep customization to meet your unique experimental needs. Contact us today to enhance your lab's efficiency and performance!

Visual Guide

Related Products

- Ultra Vacuum Electrode Feedthrough Connector Flange Power Lead for High Precision Applications

- Laboratory Vacuum Tilt Rotary Tube Furnace Rotating Tube Furnace

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- CF KF Flange Vacuum Electrode Feedthrough Lead Sealing Assembly for Vacuum Systems

People Also Ask

- Why is a high-purity quartz glass stirring rod used for phosphor dispersion? Key Benefits for Optical Glass Purity

- Why are high-purity alumina crucibles necessary for Li2Mg3Ti(1-x)ZrxO6 sintering? Ensure Dielectric Excellence

- What advantages do boron nitride (BN) crucibles offer for molten FUNaK salt? Ensure Purity & High-Temp Stability

- How are constant temperature water baths and drying ovens utilized to verify bonding quality? Master EN 314-1 Testing

- Why is the low thermal expansion of quartz important for laboratory applications? Ensure Safety and Precision in High-Heat Experiments

- What is the advantage of the circulating water multifunctional vacuum pump being one machine for multiple purposes? Streamline Lab Work Efficiently

- What are the alternative names for a Laboratory Furnace? Find the Right High-Temperature Tool for Your Lab

- Why is a precision constant temperature drying oven required for BZT ceramic powders? Ensure Perfect Powder Quality