At its core, a circulating water multifunctional vacuum pump is characterized by its oil-free, low-noise, and portable design. It uses water as its working medium to create a vacuum, making it a clean and convenient solution for a wide range of common laboratory and small-scale production tasks without the risk of oil contamination.

The central advantage of this pump is its operational principle: it leverages a simple, robust "liquid piston" mechanism using water. This eliminates the need for oil, resulting in a cleaner vacuum and significantly lower maintenance compared to traditional oil-sealed pumps.

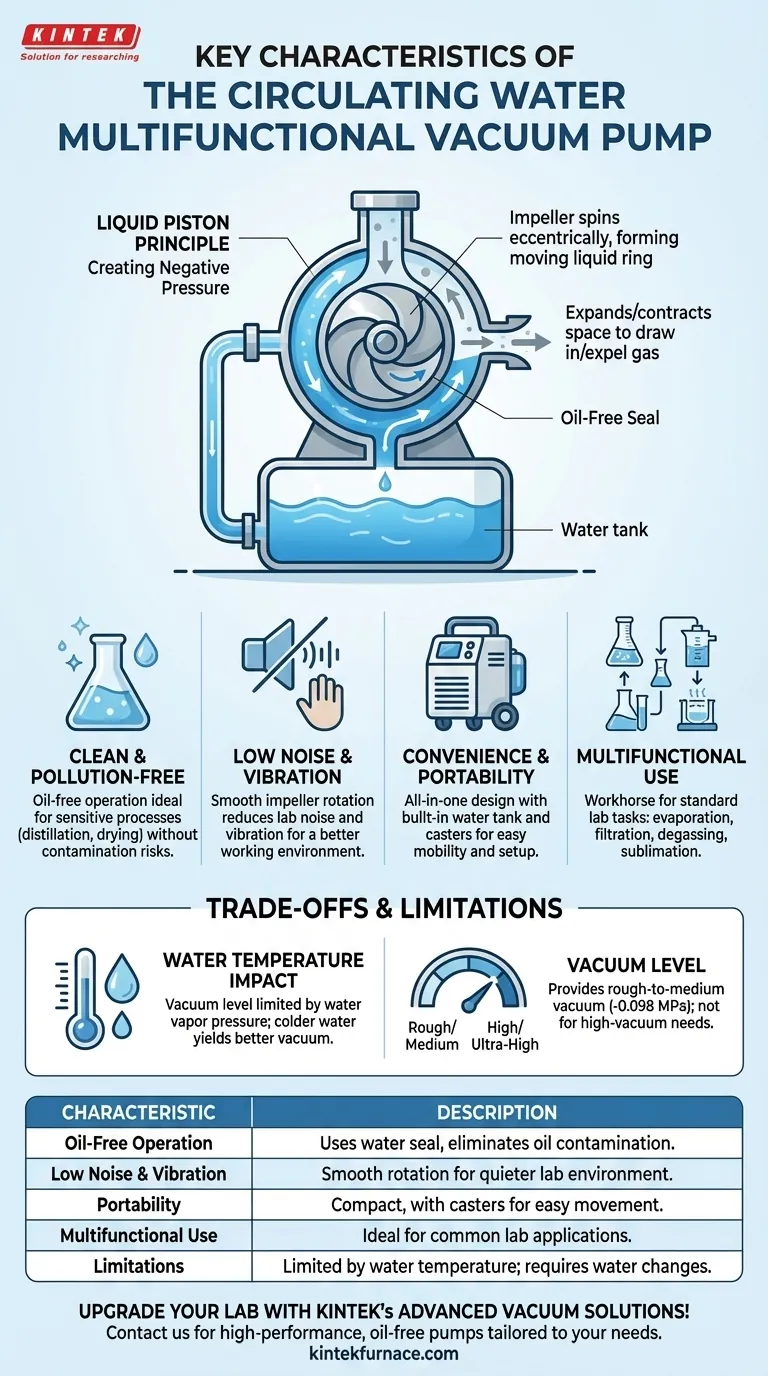

How It Works: The "Liquid Piston" Principle

To understand its characteristics, you must first understand how it operates. Unlike pumps that use mechanical pistons or oil, this device uses the physics of moving water to generate negative pressure.

The Role of Circulating Water

The pump uses water as the exclusive working fluid. This water is held in a self-contained tank and is continuously circulated, which is why it's often called a "water ring" vacuum pump.

Creating Negative Pressure

An impeller spins eccentrically (off-center) inside a cylindrical pump casing. Centrifugal force throws the water against the outer wall, forming a moving ring of liquid.

Because the impeller is off-center, the space between the impeller blades and the water ring continuously expands and contracts. This mimics a series of reciprocating "liquid pistons."

As the volume expands, it draws gas in from the vacuum port. As it contracts, it compresses the gas and expels it, creating a steady vacuum.

Why This Design is Oil-Free

The water itself forms the seal and acts as the compression medium. This elegant design completely eliminates the need for lubricating or sealing oil, preventing any possibility of oil vapor backstreaming and contaminating your experiment.

Key Functional Characteristics

The unique operating principle directly leads to the pump's most valued features.

Clean and Pollution-Free Operation

Because it uses no oil, it is ideal for processes where purity is critical. Applications like distillation, drying, and crystallization benefit from a vacuum source that introduces no foreign contaminants.

Convenience and Portability

These pumps are typically designed as compact, all-in-one units. With a built-in water tank (e.g., 15 liters) and casters for mobility, they can be easily moved around a lab and set up for different experiments without complex installation.

Low Noise and Vibration

The smooth rotation of the impeller within the water ring generates significantly less noise and vibration than the mechanical action of many other pump types, contributing to a better working environment.

Multifunctional Use

This pump is a workhorse for standard laboratory vacuum needs. It is perfectly suited for research experiments and small-scale processes like evaporation, filtration, degassing, and sublimation.

Understanding the Trade-offs and Limitations

While highly effective, it's crucial to understand the limitations inherent in this design to ensure it meets your needs.

The Impact of Water Temperature

The ultimate vacuum level this pump can achieve is physically limited by the vapor pressure of the water being used. Warmer water has a higher vapor pressure, which means it will produce a weaker (less deep) vacuum. For the deepest vacuum, using cold water is essential.

Water Quality and Maintenance

The water in the tank can become contaminated over time, especially if pulling in acidic or corrosive vapors. The water should be changed periodically to maintain performance and prevent damage to the pump's internal components.

Vacuum Level vs. High-Vacuum Pumps

A circulating water pump provides a "rough" to "medium" vacuum (e.g., down to -0.098 MPa). It cannot achieve the "high" or "ultra-high" vacuum levels produced by more complex systems like turbomolecular or oil diffusion pumps.

Making the Right Choice for Your Goal

Selecting a vacuum pump requires matching the technology to the task.

- If your primary focus is general lab applications like filtration, evaporation, or distillation: The circulating water pump is an excellent, clean, and low-maintenance choice.

- If your primary focus is achieving ultra-high vacuum for sensitive surface science or mass spectrometry: You will need a more advanced system, such as a turbomolecular or ion pump.

- If your primary focus is portability and minimizing contamination risk: This pump's oil-free, self-contained design offers significant advantages over traditional oil-sealed rotary vane pumps.

Understanding this pump's simple yet effective principle empowers you to select the right vacuum source for your specific scientific objective.

Summary Table:

| Characteristic | Description |

|---|---|

| Oil-Free Operation | Uses water as a seal, eliminating oil contamination for clean processes. |

| Low Noise and Vibration | Smooth impeller rotation reduces noise, improving the lab environment. |

| Portability | Compact, all-in-one design with casters for easy movement and setup. |

| Multifunctional Use | Ideal for evaporation, filtration, degassing, and other common lab tasks. |

| Limitations | Vacuum level limited by water temperature; requires periodic water changes. |

Upgrade your laboratory with KINTEK's advanced vacuum solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse labs with high-performance, oil-free vacuum pumps tailored to your needs. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by strong deep customization capabilities to precisely meet your unique experimental requirements. Contact us today to discuss how our solutions can enhance your efficiency and ensure contamination-free operations!

Visual Guide

Related Products

- Ultra Vacuum Electrode Feedthrough Connector Flange Power Lead for High Precision Applications

- Laboratory Vacuum Tilt Rotary Tube Furnace Rotating Tube Furnace

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- CF KF Flange Vacuum Electrode Feedthrough Lead Sealing Assembly for Vacuum Systems

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

People Also Ask

- What is a vacuum chamber good for? Mastering Material Processing with Environmental Control

- What is the purpose of applying Boron Nitride (BN) to graphite molds in Mg3Sb2 VHP? Ensure Purity & Easy Demolding

- What is the function of a laboratory electric blast drying oven in biomass pretreatment? Standardize Your Samples

- What role does specialized graphite adhesive play? Expert Bonding Solutions for High-Temp Systems

- What advantages does a vacuum drying oven offer for BiFeO3 electrode sheets? Optimize Your Battery Research

- What role do quartz tubes and vacuum sealing play in synthesis? Master High-Reactivity Compounds like U0.92Mn3Si2C

- Why is it necessary to use alumina or ceramic crucibles during the high-temperature evaporation of magnesium? Ensure Purity and Process Integrity

- Why is a vacuum pump used to evacuate the thermal modification chamber? Ensure Safety and Material Integrity