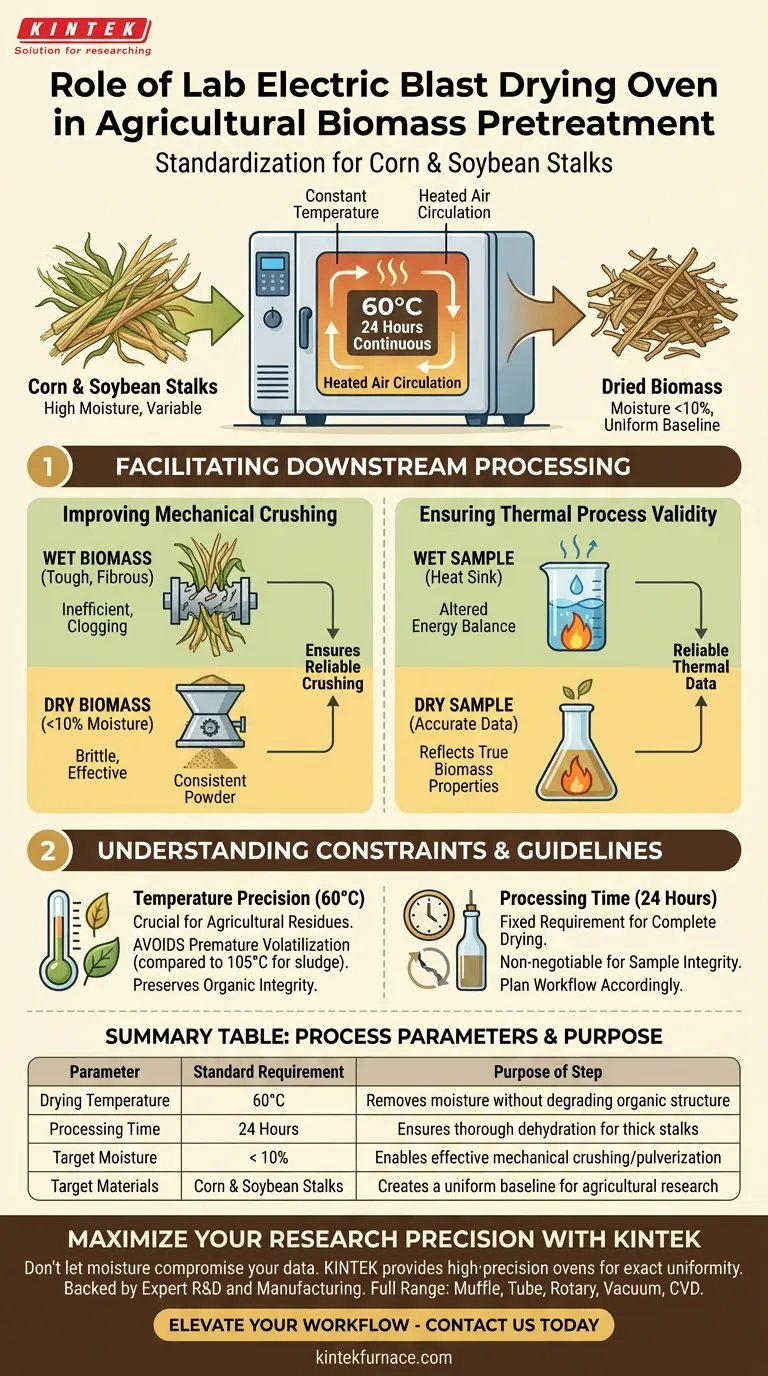

The laboratory electric blast drying oven acts as the foundational standardization step for processing agricultural biomass residues. Its specific function is to subject materials like corn and soybean stalks to a constant temperature of 60°C for 24 hours, effectively reducing the moisture content to below 10%.

By eliminating natural moisture fluctuations found in raw crops, the drying oven creates a stable, uniform baseline that is strictly necessary for accurate crushing and reliable thermal processing data.

The Role of Standardization in Biomass Pretreatment

Establishing a Controlled Environment

Raw agricultural residues vary significantly in moisture content depending on harvest conditions and storage. The electric blast drying oven mitigates this variable by circulating heated air at a precise temperature.

The 60°C / 24-Hour Protocol

For agricultural biomass specifically, the standard operation involves heating at 60°C for a continuous 24-hour cycle.

This specific parameter is crucial. Unlike industrial sludges that may require temperatures over 100°C, agricultural stalks are processed at this moderate heat to remove moisture without aggressively degrading the organic structure before the main experiment begins.

Reaching the Critical Moisture Threshold

The primary target of this process is to lower the biomass moisture content to below 10%.

Achieving this low-moisture state is the definition of a "dried sample" in this context. It ensures that the water weight does not skew mass measurements or chemical analysis later in the workflow.

Facilitating Downstream Processing

Improving Mechanical Crushing

Drying is a prerequisite for the mechanical size reduction of corn and soybean stalks.

Wet biomass is fibrous, tough, and prone to tearing rather than shattering. By reducing moisture to below 10%, the oven renders the stalks brittle, ensuring they can be crushed effectively into a consistent powder.

Ensuring Thermal Process Validity

The blast drying oven prepares the sample for subsequent thermal processing stages.

If moisture is not removed beforehand, it acts as a heat sink during thermal experiments, altering the energy balance. Pre-drying ensures that any thermal data collected reflects the properties of the biomass itself, not the evaporation of excess water.

Understanding the Constraints

The Importance of Temperature Precision

You must adhere strictly to the 60°C set point for agricultural residues.

While other materials (like sludge) are dried at 105°C to remove free water, applying that higher temperature to agricultural biomass could prematurely volatilize organic compounds. This would alter the chemical composition of your sample before the experiment even begins.

Processing Time vs. Throughput

The 24-hour cycle is a fixed requirement for complete drying.

This creates a bottleneck in the workflow; you cannot speed up the process by increasing heat without compromising sample integrity. Planning your experimental timeline must account for this non-negotiable conditioning period.

Making the Right Choice for Your Goal

To ensure your pretreatment yields valid scientific data, apply the following guidelines:

- If your primary focus is Physical Processing: Ensure the 24-hour cycle is fully completed to reach <10% moisture, or the biomass may clog your crushing equipment.

- If your primary focus is Chemical Analysis: Strictly monitor the 60°C limit to preserve the organic integrity of the corn and soybean stalks while removing water weight.

Reliable data begins with a consistent sample; the drying oven is the tool that guarantees that consistency.

Summary Table:

| Process Parameter | Standard Requirement | Purpose of Step |

|---|---|---|

| Drying Temperature | 60°C | Removes moisture without degrading organic structure |

| Processing Time | 24 Hours | Ensures thorough dehydration for thick stalks |

| Target Moisture | < 10% | Enables effective mechanical crushing/pulverization |

| Target Materials | Corn & Soybean Stalks | Creates a uniform baseline for agricultural research |

Maximize Your Research Precision with KINTEK

Don't let moisture fluctuations compromise your biomass data. KINTEK provides high-precision laboratory ovens and thermal processing systems designed to deliver the exact temperature uniformity your standardization protocols require.

Backed by expert R&D and manufacturing, we offer a full range of Muffle, Tube, Rotary, Vacuum, and CVD systems, all fully customizable to meet the unique needs of agricultural and material science labs.

Ready to elevate your pretreatment workflow? Contact our specialists today to find the perfect drying solution for your lab.

Visual Guide

References

- Đurđica Kovačić, Mladen Jurišić. Influence of Thermal Pretreatment on Lignin Destabilization in Harvest Residues: An Ensemble Machine Learning Approach. DOI: 10.3390/agriengineering6010011

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1200℃ Muffle Oven Furnace for Laboratory

- Electric Rotary Kiln Pyrolysis Furnace Plant Machine Small Rotary Kiln Calciner

- Electric Rotary Kiln Continuous Working Small Rotary Furnace Kiln for Pyrolysis Plant Heating

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

People Also Ask

- How is an industrial electric heating drying oven utilized in the pretreatment of copper-graphite composite materials?

- What is the purpose of using a high-purity argon system for AlCoCrFeNi melting? Preserve Alloy Stoichiometry

- Why is the pore size of refractory materials significant? Unlocking Precision in Bubble Formation and Oxygen Impact

- What are the advantages of water circulating vacuum pumps? Discover Oil-Free, Reliable Solutions for Clean Processes

- What temperature range can graphite crucible furnaces withstand? Achieve Extreme Heat for High-Melting Metals

- What is the specific significance of using high-purity corundum crucibles in oxidation weight gain experiments?

- What roles do high-purity graphite molds play during the Spark Plasma Sintering (SPS) of Ba0.95La0.05FeO3-δ? Essential Guide

- Why is a vacuum pump necessary for bio-adsorbent performance assessments? Ensuring Industrial Viability in VSA