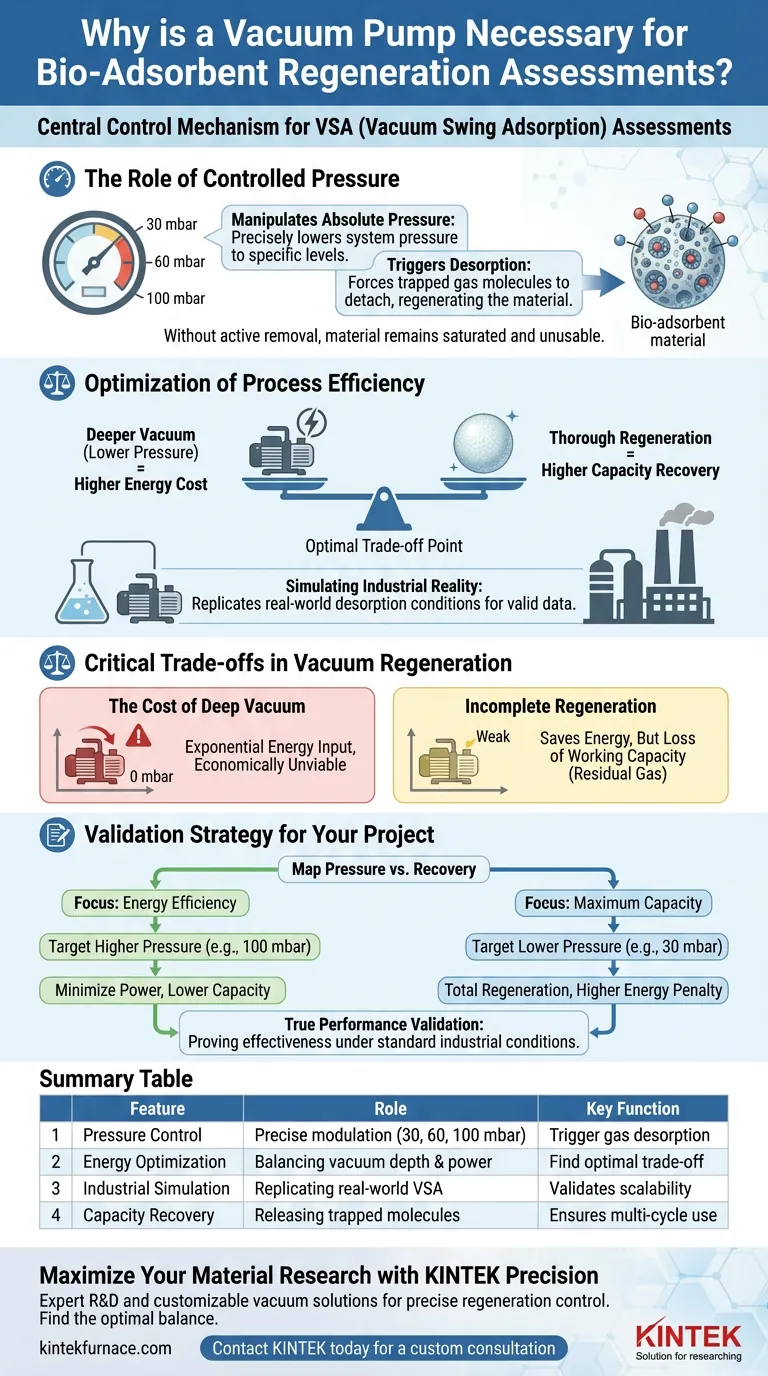

A vacuum pump serves as the central control mechanism for the regeneration phase in Vacuum Swing Adsorption (VSA) assessments. Its primary function is to lower the absolute pressure within the system, forcing the bio-adsorbent material to release trapped molecules so it can be reused. By precisely modulating this pressure, researchers can simulate the exact desorption conditions found in industrial applications.

The vacuum pump allows for the precise adjustment of absolute pressure to determine the optimal balance between energy consumption and the recovery of adsorption capacity. This validation step is strictly necessary to prove a bio-adsorbent’s viability for real-world scaling.

The Role of Controlled Pressure

Manipulating Absolute Pressure

The effectiveness of a bio-adsorbent is not just about how much it can hold, but how easily it releases what it has captured.

The vacuum pump creates a controlled environment where the absolute pressure can be adjusted to specific levels. Common benchmarks for these assessments include pressures such as 30, 60, or 100 mbar.

Triggering Desorption

At these reduced pressures, the physical bond between the adsorbent and the gas molecules weakens.

This forces the gas to desorb, or detach, from the material's surface. Without a vacuum pump to actively remove these molecules and lower the pressure, the material would remain saturated and unusable for subsequent cycles.

Optimization of Process Efficiency

Balancing Energy and Capacity

A deeper vacuum (lower pressure) cleans the material more thoroughly, but it comes at a cost.

The primary goal of using a variable vacuum pump is to identify the optimal trade-off point. Researchers must find the specific pressure level where the material recovers enough capacity to be useful without expending excessive energy to run the pump.

Simulating Industrial Reality

Lab-scale tests must mirror the constraints of large-scale plants to be valid.

By using a vacuum pump to replicate industrial vacuum desorption conditions, assessments provide data that is actually relevant to engineers. It moves the bio-adsorbent from a theoretical concept to a verified solution ready for process integration.

Critical Trade-offs in Vacuum Regeneration

The Cost of Deep Vacuum

Achieving extremely low pressures (e.g., nearing 0 mbar) yields near-perfect regeneration but requires exponential energy input.

Operating at the limits of the vacuum pump can make the VSA process economically unviable, regardless of how good the bio-adsorbent is.

Incomplete Regeneration

Conversely, using a weak vacuum saves energy but leaves residual gas trapped in the material.

This "working capacity" loss means the adsorbent becomes less effective with every cycle. The vacuum pump is the tool used to dial in the exact compromise between these two extremes.

Validation Strategy for Your Project

To ensure your bio-adsorbent assessment is industrially relevant, you must use the vacuum pump to map the relationship between pressure and recovery.

- If your primary focus is Energy Efficiency: Target higher pressure setpoints (e.g., 100 mbar) to minimize pump power, accepting slightly lower capacity recovery.

- If your primary focus is Maximum Capacity: Test at lower pressure setpoints (e.g., 30 mbar) to ensure total material regeneration, while monitoring the associated energy penalty.

True performance validation requires proving that your material regenerates effectively under the specific vacuum conditions available in standard industrial equipment.

Summary Table:

| Feature | Role in Regeneration Assessment |

|---|---|

| Pressure Control | Precise modulation (e.g., 30, 60, 100 mbar) to trigger gas desorption |

| Energy Optimization | Finding the balance between vacuum depth and operational power costs |

| Industrial Simulation | Replicating real-world Vacuum Swing Adsorption (VSA) conditions |

| Capacity Recovery | Ensuring the material releases trapped molecules for multi-cycle use |

Maximize Your Material Research with KINTEK Precision

Transitioning from lab-scale bio-adsorbent tests to industrial-ready solutions requires high-performance vacuum environments. Backed by expert R&D and manufacturing, KINTEK offers a wide range of specialized laboratory equipment, including Muffle, Tube, Rotary, Vacuum, and CVD systems.

Our customizable high-temperature furnaces and vacuum solutions are designed to meet the unique needs of researchers seeking precise control over regeneration conditions. Let our experts help you find the optimal balance between energy efficiency and adsorption capacity.

Ready to elevate your process? Contact KINTEK today for a custom consultation.

Visual Guide

References

- A Coffee-Based Bioadsorbent for CO2 Capture from Flue Gas Using VSA: TG-Vacuum Tests. DOI: 10.3390/en18153965

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- CF KF Flange Vacuum Electrode Feedthrough Lead Sealing Assembly for Vacuum Systems

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- 304 316 Stainless Steel High Vacuum Ball Stop Valve for Vacuum Systems

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

People Also Ask

- What is the necessity of a cylindrical condenser in a microwave-assisted metal reduction system? Key Protection Insights

- How does a laboratory vacuum pump system contribute to the preparation process of TixNbMoTaW refractory alloys?

- What are the requirements for high-temperature heating equipment and quartz crucibles in incineration ash pretreatment?

- What is the purpose of cleaning MgO substrates for ScN growth? Optimize Your Epitaxial Film Quality

- How does a laboratory drying oven function in catalyst synthesis? Secure Precision Metal Precursor Stabilization

- What role does a high-alumina ceramic boat play during Ni-Co doped carbon nanotube growth? Key CVD Synthesis Insights

- Why are high-purity alumina crucibles preferred over quartz crucibles at 1873 K? Ensure Precision at Extreme Heat

- What are the preparation steps for a water circulating vacuum pump? Ensure Optimal Performance and Longevity