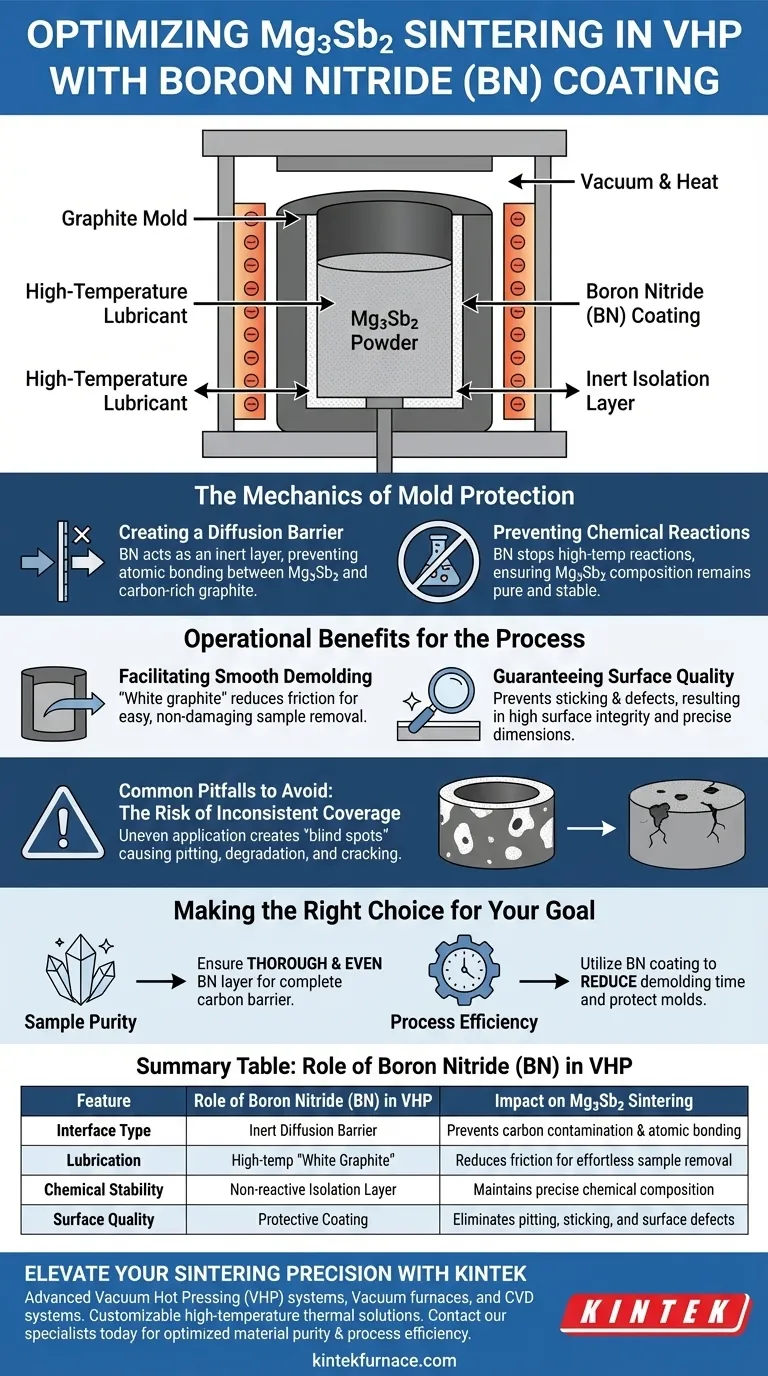

Applying Boron Nitride (BN) to graphite molds serves as a critical protective measure during the Vacuum Hot Pressing (VHP) of Mg3Sb2 powder. This coating functions primarily as a high-temperature lubricant and an isolation layer, preventing the powder from chemically reacting with or sticking to the graphite under intense heat and pressure.

Vacuum Hot Pressing exposes materials to conditions that naturally promote unwanted adhesion and chemical bonding. A Boron Nitride coating neutralizes this risk by acting as an inert interface, ensuring the final sintered body remains pure, intact, and easy to remove from the mold.

The Mechanics of Mold Protection

Creating a Diffusion Barrier

In the high-temperature environment of VHP, materials are prone to diffusion bonding. Boron Nitride acts as an inert isolation layer between the Mg3Sb2 powder and the carbon-rich graphite. This physical separation prevents the sample from bonding with the mold walls at the atomic level.

Preventing Chemical Reactions

Direct contact between the powder and the mold can lead to unwanted chemical changes. The BN coating stops these high-temperature reactions from occurring. This ensures the chemical composition of the Mg3Sb2 remains stable and uncontaminated by the graphite.

Operational Benefits for the Process

Facilitating Smooth Demolding

Boron Nitride is often referred to as "white graphite" due to its lubricious properties. It serves as a release agent that significantly reduces friction between the sintered body and the mold walls. This allows you to remove the sample easily without applying excessive force that could damage it.

Guaranteeing Surface Quality

Adhesion to the mold is the primary cause of surface defects in sintered samples. By preventing sticking and chemical interaction, the BN layer preserves the integrity of the sample's exterior. This results in a final product with high surface quality and precise dimensions.

Common Pitfalls to Avoid

The Risk of Inconsistent Coverage

While Boron Nitride is effective, it must be applied uniformly. Any gaps in the coating create "blind spots" where the Mg3Sb2 can still react with or adhere to the graphite. This leads to localized pitting, surface degradation, and potential cracking during the demolding process.

Making the Right Choice for Your Goal

To maximize the success of your Vacuum Hot Pressing process, consider your specific priorities:

- If your primary focus is Sample Purity: Ensure the BN layer is applied thoroughly and evenly to completely block carbon diffusion from the graphite mold.

- If your primary focus is Process Efficiency: Utilize the BN coating to reduce demolding time and protect the graphite mold for repeated use.

A properly coated mold is the single most effective way to ensure the structural and chemical integrity of your sintered Mg3Sb2.

Summary Table:

| Feature | Role of Boron Nitride (BN) in VHP | Impact on Mg3Sb2 Sintering |

|---|---|---|

| Interface Type | Inert Diffusion Barrier | Prevents carbon contamination and atomic bonding |

| Lubrication | High-temp "White Graphite" | Reduces friction for effortless sample removal |

| Chemical Stability | Non-reactive Isolation Layer | Maintains precise chemical composition of powder |

| Surface Quality | Protective Coating | Eliminates pitting, sticking, and surface defects |

Elevate Your Sintering Precision with KINTEK

Achieving high-quality sintered bodies like Mg3Sb2 requires both technical expertise and superior equipment. KINTEK provides advanced Vacuum Hot Pressing (VHP) systems, Vacuum furnaces, and CVD systems, all supported by our expert R&D and manufacturing teams. Whether you need standard lab equipment or a fully customizable high-temperature furnace tailored to your unique material needs, we are here to help.

Ready to optimize your material purity and process efficiency? Contact our specialists today to find the perfect thermal solution for your laboratory.

Visual Guide

Related Products

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

People Also Ask

- What role do mass flow controllers play in gasification? Achieve Precise Atmosphere Control in Lab Furnaces

- What types of trays are compatible with MoSi2 heating elements? Ensure Optimal Performance and Longevity

- Why is a high-purity quartz glass reactor preferred over a metal reactor? Achieve 4.5N Purity in Al Powder Reduction

- Why use high-alumina (Alundum) crucibles for monazite glass-ceramic synthesis? Ensure Purity in High-Heat Research

- What is the function of a ceramic crucible with a lid during g-C3N4 synthesis? Optimize Your Polycondensation Results

- What is the primary role of laboratory furnaces in manufacturing and scientific processes? Unlock Precision Thermal Control

- What is the primary function of a high-alumina powder crucible? Ensure Purity in Maraging Steel Pre-treatment

- Why use a graphite box for WS2 sulfurization? Essential for High-Quality Thin Film Synthesis