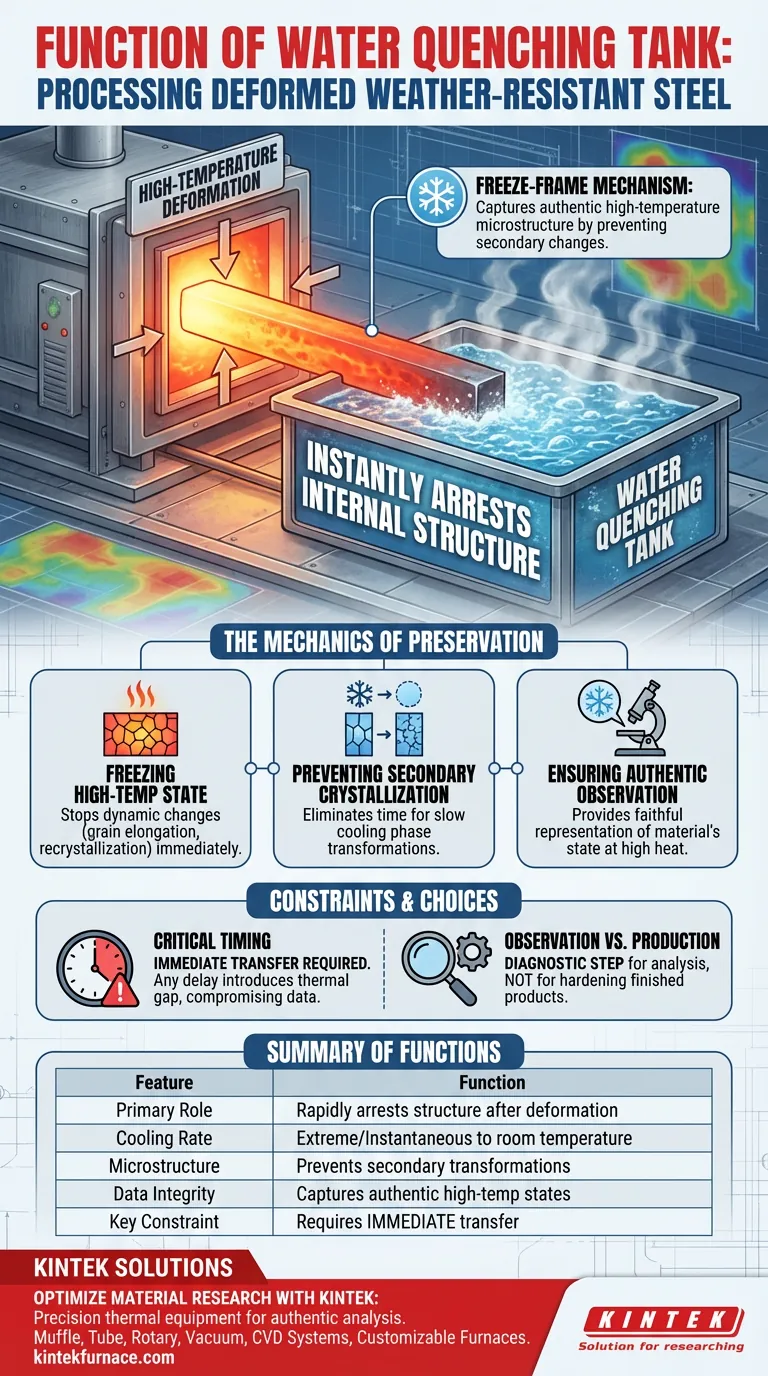

The primary function of a water quenching tank in this context is to rapidly arrest the internal structure of weather-resistant steel immediately following high-temperature deformation. By submerging the specimen in water, the tank delivers an extreme cooling rate that drops the material to room temperature instantly. This process is essential for preserving the specific microstructural state that existed at the precise moment of compression.

Core Takeaway Water quenching acts as a "freeze-frame" mechanism for materials science. By preventing natural cooling processes, it allows researchers to capture and analyze the authentic high-temperature microstructure of the steel before it can be altered by secondary phase transformations.

The Mechanics of Microstructural Preservation

Freezing the High-Temperature State

When steel is deformed at high temperatures, its internal structure changes dynamically. These changes include grain elongation, recrystallization, or the formation of new phases.

To study these changes, researchers must capture the steel exactly as it is during the deformation process. The water quenching tank serves as the "stop button" for these thermal and mechanical reactions.

Preventing Secondary Crystallization

If a hot steel specimen is allowed to cool slowly in the air, the microstructure will continue to evolve. This process is known as secondary crystallization or phase transformation.

Slow cooling allows grains to grow or change shape, obscuring the effects of the deformation. Water quenching eliminates the time window required for these secondary changes to occur.

Ensuring Authentic Observation

The ultimate goal of using a water quenching tank is data integrity. Researchers need to observe the authentic microstructural characteristics formed solely by the hot deformation process.

By freezing the structure instantly, the specimen analyzed under a microscope at room temperature is a faithful representation of the material's state at high heat.

Understanding the Constraints

The Criticality of Timing

The effectiveness of the water quenching tank is entirely dependent on the speed of transfer. The reference emphasizes that cooling must occur immediately following high-temperature compression.

Any delay between the deformation equipment and the water tank introduces a "thermal gap." During this gap, the microstructure may begin to relax or transform, rendering the resulting data inaccurate.

Observation vs. Production Simulation

It is important to distinguish this process from standard heat treatment. In this specific context, the quenching is not intended to harden the steel for use.

Instead, it is a diagnostic step. The resulting specimen represents a frozen moment in time for analysis, rather than a finished product prepared for structural application.

Making the Right Choice for Your Goal

The use of a water quenching tank is a deliberate strategic choice based on what you need to measure.

- If your primary focus is microstructural analysis: Ensure immediate transfer to the water tank to freeze the grain structure and prevent secondary phase transformations.

- If your primary focus is simulating real-world cooling: Avoid the water quenching tank and utilize a cooling method that mimics the actual production environment (such as air cooling) to observe how the steel behaves naturally.

In summary, the water quenching tank is the critical tool that converts a dynamic, high-temperature event into a static, observable specimen.

Summary Table:

| Feature | Function in Deformed Steel Processing |

|---|---|

| Primary Role | Rapidly arrests internal structure after high-temp deformation |

| Cooling Rate | Extreme/Instantaneous cooling to room temperature |

| Microstructure | Prevents secondary crystallization and phase transformations |

| Data Integrity | Captures authentic high-temperature grain states for analysis |

| Key Constraint | Requires immediate transfer to prevent thermal relaxation |

Optimize Your Material Research with KINTEK

Precision in microstructural analysis begins with the right thermal equipment. Backed by expert R&D and manufacturing, KINTEK offers a comprehensive range of Muffle, Tube, Rotary, Vacuum, and CVD systems, along with specialized lab high-temperature furnaces—all fully customizable to meet your unique metallurgical research needs.

Whether you are studying phase transformations in weather-resistant steel or developing new alloys, our advanced heating solutions provide the thermal stability and control essential for authentic data. Ready to elevate your lab's capabilities? Contact us today to discuss your custom furnace requirements!

Visual Guide

References

- Jianwei Cheng. Research on hot deformation characterization of a new weathering steel through processing map and microstructural observation. DOI: 10.1038/s41598-025-86619-2

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Vacuum Heat Treat Sintering and Brazing Furnace

People Also Ask

- What is the purpose of a water-cooling jacket in a methane cracking reactor? Prevent Blockages & Thermal Damage

- How does a vacuum pump facilitate the synthesis process of rare earth-based halide electrolytes? Boost Chemical Purity

- What are the advantages of using a platinum crucible? Essential for High-Purity Alumino-Borosilicate Glass Synthesis

- What is the function of a high-purity porcelain crucible? Expert Guide to Chromium-Doped Borosilicate Glass Preparation

- What are the specific functions of a magnetic stirrer and a condenser reflux apparatus in the synthesis of KCC-1? Expert Insights

- What role does a high-precision mass flow controller play in assessing the gas selectivity of Gallium Sulfide sensors?

- How does a Rapid Thermal Annealing (RTA) system differ from a standard hotplate? Optimize Perovskite Crystallization

- What are the advantages of using high-purity graphite molds for transient exothermic welding? Precision & Pure Bonding