High-purity graphite molds offer a critical combination of thermal, electrical, and mechanical stability necessary for precise transient exothermic welding. They provide uniform pressure and mechanical support while conducting the current needed to trigger reactions. Crucially, their chemical inertness prevents contamination, making them indispensable for high-purity applications like semiconductor packaging.

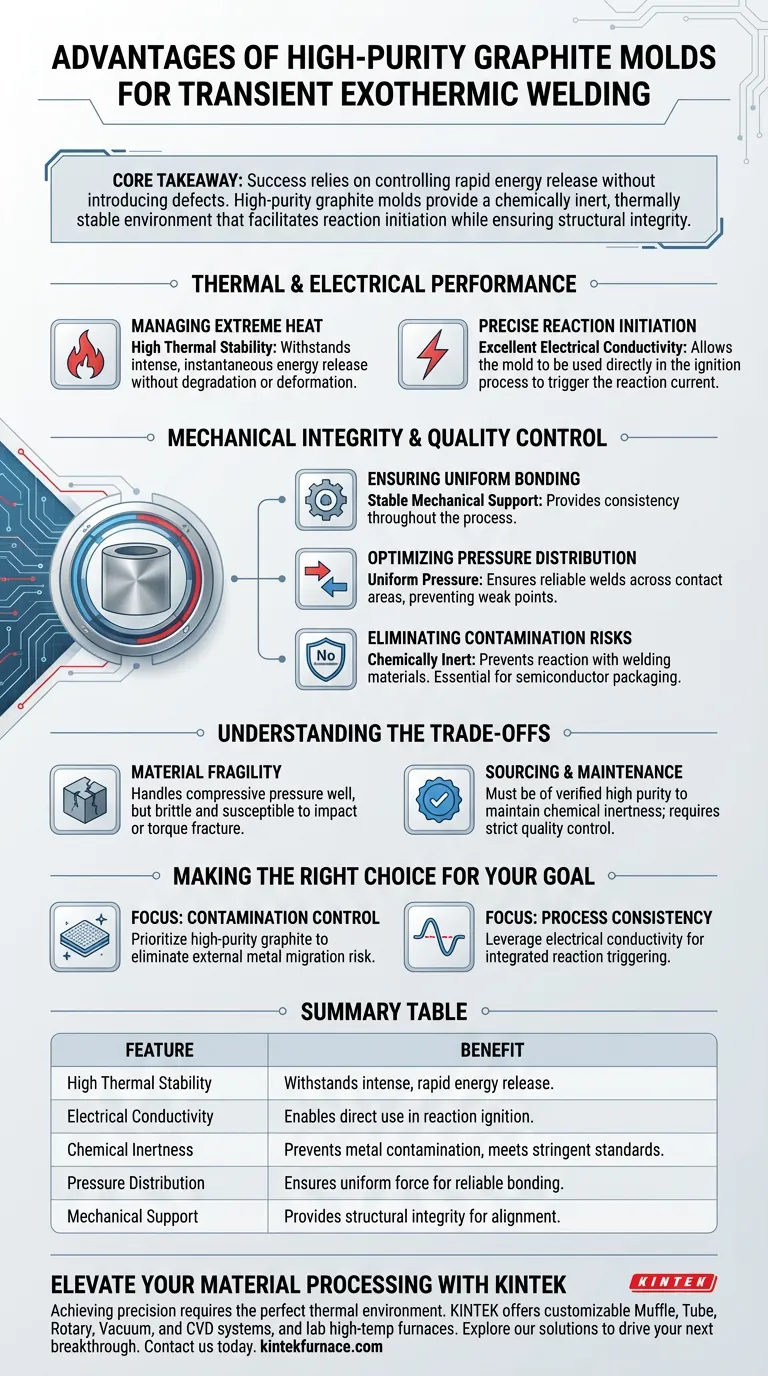

Core Takeaway Success in transient exothermic welding relies on controlling rapid energy release without introducing defects. High-purity graphite molds solve this by offering a chemically inert, thermally stable environment that facilitates reaction initiation while ensuring structural integrity.

Thermal and Electrical Performance

Managing Extreme Heat

Exothermic reactions, such as those in Al/Ni multilayer films, release intense energy in a fraction of a second. Graphite molds possess high thermal stability, allowing them to withstand these instantaneous high temperatures without degrading or deforming.

Precise Reaction Initiation

Unlike insulating mold materials, graphite offers excellent electrical conductivity. This property allows the mold to be utilized directly in the ignition process, effectively helping to trigger the reaction current required to start the weld.

Mechanical Integrity and Quality Control

Ensuring Uniform Bonding

Consistency is paramount in welding micro-components. Graphite molds provide stable mechanical support throughout the process.

Optimizing Pressure Distribution

To achieve a reliable weld, the force applied to the materials must be consistent. Graphite ensures uniform pressure distribution across the contact area, preventing weak points or uneven bonding.

Eliminating Contamination Risks

In sensitive industries, foreign material can ruin a device. Graphite is chemically inert, meaning it does not react with the welding materials.

Suitability for Semiconductor Packaging

Because graphite ensures that no external metal contamination is introduced during the process, it meets the stringent cleanliness standards required for semiconductor packaging and other high-purity electronics.

Understanding the Trade-offs

Material Fragility

While graphite offers excellent thermal stability, it is mechanically different from steel or alloy molds. It acts more like a ceramic; while it handles compressive pressure well, it can be brittle and susceptible to fracture if subjected to impacts or torque outside of its design parameters.

Sourcing and Maintenance

To maintain the advantage of "no external metal contamination," the graphite itself must be of verified high purity. Using lower-grade graphite can negate the chemical inertness benefit, requiring strict quality control over the mold material itself.

Making the Right Choice for Your Goal

- If your primary focus is contamination control: Prioritize high-purity graphite to eliminate the risk of external metal migration into sensitive semiconductor components.

- If your primary focus is process consistency: Leverage graphite’s electrical conductivity to integrate reaction triggering directly into the mechanical support structure.

By utilizing high-purity graphite, you align the welding environment with the physics of the reaction, ensuring a defect-free, high-integrity bond.

Summary Table:

| Feature | Benefit for Exothermic Welding |

|---|---|

| High Thermal Stability | Withstands intense, rapid energy release without deformation or degradation. |

| Electrical Conductivity | Enables the mold to be utilized directly in the reaction ignition process. |

| Chemical Inertness | Prevents metal contamination, meeting stringent semiconductor packaging standards. |

| Pressure Distribution | Ensures uniform force across contact areas for reliable, defect-free bonding. |

| Mechanical Support | Provides the structural integrity needed to maintain alignment during reactions. |

Elevate Your Material Processing with KINTEK

Achieving precision in transient exothermic welding requires not only the right molds but also the perfect thermal environment. Backed by expert R&D and manufacturing, KINTEK offers a comprehensive range of Muffle, Tube, Rotary, Vacuum, and CVD systems, as well as other lab high-temp furnaces—all fully customizable to meet your unique experimental and production needs.

Whether you are working with sensitive semiconductor packaging or advanced multilayer films, our systems provide the stability and control necessary for high-integrity results. Contact us today to explore our solutions and see how our expertise can drive your next breakthrough.

Visual Guide

References

- Wafer Bonding Technologies for Microelectromechanical Systems and 3D ICs: Advances, Challenges, and Trends. DOI: 10.1002/adem.202500342

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Magnesium Extraction and Purification Condensing Tube Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- 915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor

- CF KF Flange Vacuum Electrode Feedthrough Lead Sealing Assembly for Vacuum Systems

- Molybdenum Disilicide MoSi2 Thermal Heating Elements for Electric Furnace

People Also Ask

- What are the technical advantages of using a high-purity alumina crucible for the synthesis of MnBi2Te4?

- What is the temperature resistance of alumina ceramic tubes? Up to 1800°C for Demanding Applications

- Why is a FeCrAl alloy crucible used in CDM experiments? The Key to High-Temperature Stability

- What manufacturing processes rely on laboratory furnaces? Precision Heat Treatment for Advanced Materials

- What are the technical considerations for selecting a stainless steel cylindrical vessel? Magnesium Test Chamber Guide

- What are the benefits of the improved circulating water vacuum pump? Save Costs and Go Green in Your Lab

- Are customization options available for alumina ceramic furnace tubes? Tailor Them for Your Lab's Needs

- Why is a quartz tube selected as the sample container for emissivity measurement? Precision Microwave Heating Benefits