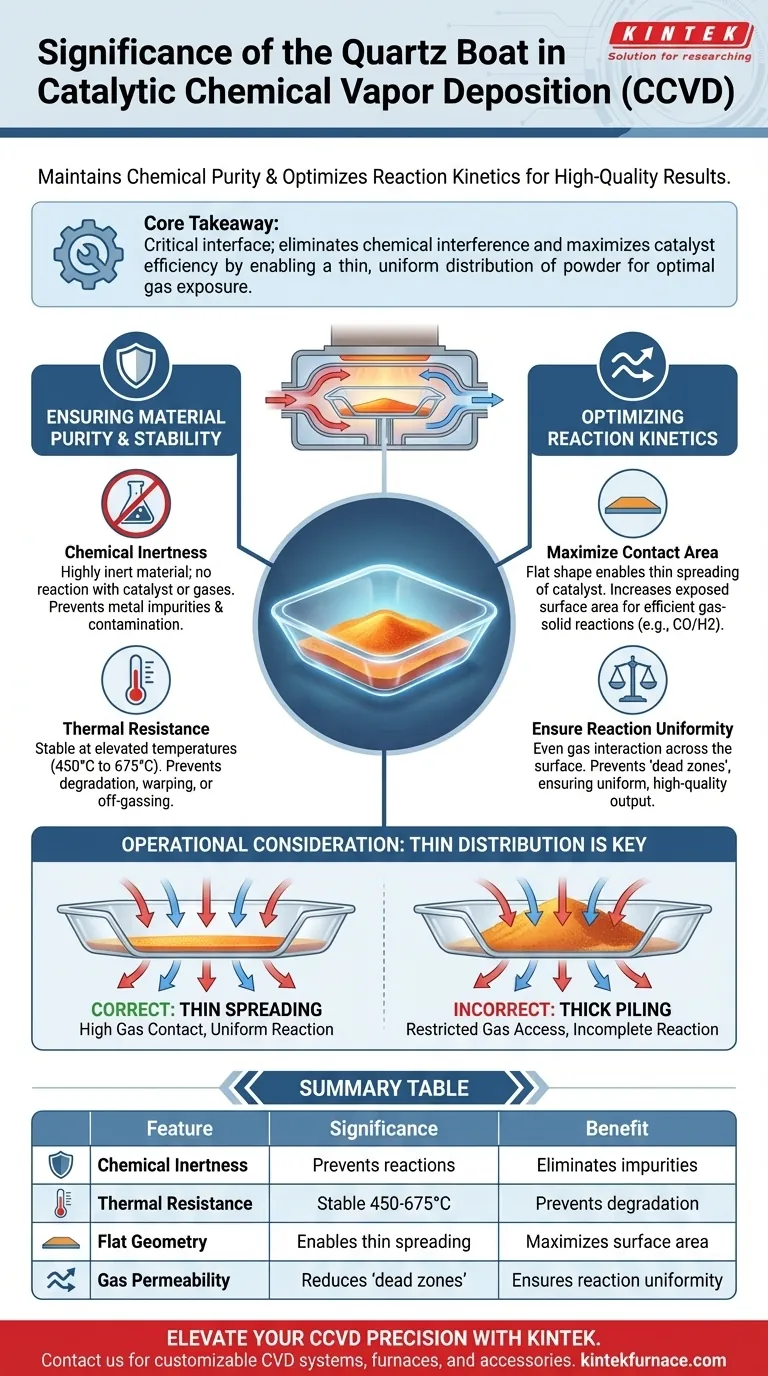

The significance of using a quartz boat in Catalytic Chemical Vapor Deposition (CCVD) lies in its ability to maintain chemical purity while optimizing reaction kinetics. This component acts as a stable, inert carrier that withstands temperatures between 450 °C and 675 °C without contaminating the process, while its physical design enhances the efficiency of the gas-solid interactions.

Core Takeaway The quartz boat serves as a critical interface in the CCVD process; it eliminates chemical interference through high inertness and maximizes catalyst efficiency by enabling a thin, uniform distribution of powder for optimal gas exposure.

Ensuring Material Purity and Stability

The primary role of the quartz boat is to provide a neutral environment that does not alter the chemical composition of the reaction.

Maintaining Chemical Inertness

The success of CCVD relies on the specific interaction between the catalyst and the reaction gases. Quartz is highly chemically inert, meaning it does not react with the catalyst or the gases involved.

This inertness ensures that no metal impurities or unwanted chemical interferences are introduced into the system. The boat acts solely as a holder, not a participant, preserving the integrity of the synthesis.

Withstanding High Thermal Loads

CCVD processes occur at elevated temperatures, specifically within the 450 °C to 675 °C range.

The quartz boat possesses the necessary high-temperature resistance to remain structurally and chemically stable under these conditions. This prevents the carrier from degrading, warping, or off-gassing, which would otherwise compromise the reaction environment.

Optimizing Reaction Kinetics

Beyond material properties, the physical geometry of the quartz boat plays a decisive role in how the reaction proceeds.

Maximizing Catalyst Contact Area

The efficiency of the CCVD process depends heavily on the gas-solid reaction between the catalyst powder and the reaction gases (such as CO/H2).

The flat shape of the quartz boat is engineered to facilitate the thin spreading of powder catalysts. This thin distribution significantly increases the exposed surface area of the catalyst.

Ensuring Reaction Uniformity

By spreading the catalyst thinly across a flat surface, the setup ensures that the reaction gases can interact with the material evenly.

This geometry guarantees the sufficiency and uniformity of the reaction. It prevents "dead zones" where gas cannot penetrate deep piles of powder, leading to a consistent and high-quality output.

Operational Considerations

While the quartz boat is the ideal carrier, its effectiveness relies on correct usage regarding catalyst loading.

The Necessity of Thin Distribution

The benefits of the quartz boat are negated if the catalyst is piled too thickly. The significance of the boat's design is specifically to allow for thin spreading.

Failing to utilize the flat surface to spread the catalyst will reduce the contact area. This restricts the access of CO and H2 gases to the catalyst material, leading to an incomplete or non-uniform reaction.

Making the Right Choice for Your Goal

To maximize the effectiveness of your CCVD process, ensure your operational techniques align with the advantages provided by the quartz boat.

- If your primary focus is high purity: Rely on the quartz boat's chemical inertness to prevent metal contamination, ensuring the boat is clean prior to loading.

- If your primary focus is reaction efficiency: Utilize the boat's flat geometry to spread the catalyst as thinly as possible, maximizing the gas-solid contact area.

Proper utilization of the quartz boat transforms it from a simple container into an active tool for process optimization.

Summary Table:

| Feature | Significance in CCVD | Benefit to Process |

|---|---|---|

| Chemical Inertness | Prevents reactions between carrier and catalyst | Eliminates metal impurities and contamination |

| Thermal Resistance | Stable at 450°C to 675°C | Prevents structural degradation or off-gassing |

| Flat Geometry | Enables thin spreading of catalyst powder | Maximizes surface area for gas-solid interactions |

| Gas Permeability | Reduces "dead zones" in catalyst layers | Ensures reaction uniformity and high-quality output |

Elevate Your CCVD Precision with KINTEK

Unlock superior material purity and reaction efficiency in your lab. Backed by expert R&D and world-class manufacturing, KINTEK provides high-performance CVD systems, Muffle, Tube, Rotary, and Vacuum furnaces—all fully customizable to meet your specific high-temperature research needs.

Ready to optimize your thermal processing? Contact our technical experts today to find the perfect furnace and accessory solution for your application.

Visual Guide

References

- Minki Sung, Seong‐Ho Yoon. Preparation Uniform Thin Tubular Carbon Nanofiber Using Novel Bimetallic Catalyst at Low Temperature and Its Structural Feature. DOI: 10.1021/acsomega.4c10295

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Vertical Laboratory Quartz Tube Furnace Tubular Furnace

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

People Also Ask

- How does a laboratory blast drying oven facilitate the conversion of acid leach liquor into solid PAFS? Key Mechanism

- What is the specific purpose of using a graphite crucible equipped with a plug during the melting process of Mg3Sb2?

- Why is precise temperature sensor placement critical in high-temp viscometers? Expert Insights for Accurate Melt Data

- Why are desiccators containing saturated salt solutions used when evaluating the hygroscopicity of modified wood?

- Why are Zirconium Dioxide (ZrO2) crucibles used for slag-metal experiments? Ensure High-Temperature Chemical Purity

- Alumina vs. Platinum Crucibles for Lithium Titanate (LTO) Synthesis: Which is Right for You?

- What is the role of a Teflon-lined autoclave in CeO2 synthesis? Achieve Pure, Monodisperse Nanomaterials

- What is the importance of using spot-welded K-type thermocouples in DP steel heat treatment? Master Thermal Precision