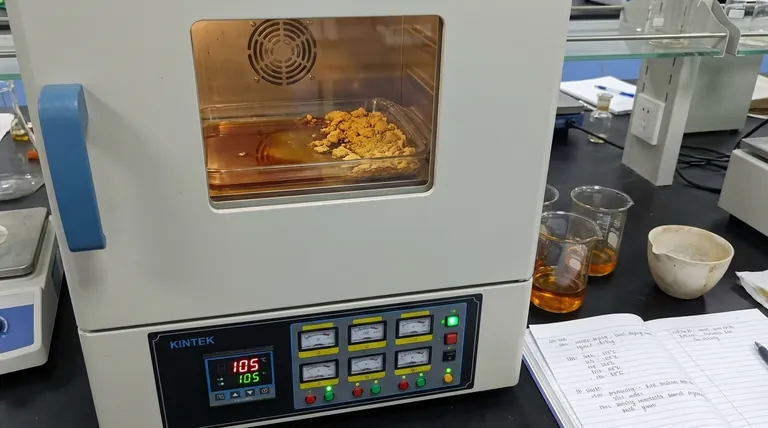

A laboratory blast drying oven facilitates the conversion of liquid polyaluminum ferric sulfate (PAFS) into solid form by utilizing controlled hot air circulation to drive moisture removal and chemical stabilization. By maintaining a constant temperature, the oven transforms the intermediate polymerized brown liquid into a durable solid suitable for industrial application.

The drying oven does more than simply evaporate water; it serves as a reactor for the final stage of synthesis. By sustaining a constant 105 °C environment, it drives the polycondensation of aluminum and iron complexes, resulting in a stable flocculant with a polycrystalline structure optimized for storage and dosing.

The Mechanism of Transformation

Controlled Thermal Dehydration

The core function of the laboratory blast drying oven is to remove moisture from the polymerized brown liquid.

The oven utilizes forced hot air circulation to ensure even heat distribution. This process slowly and consistently evaporates the solvent from the acid leach liquor derivative without degrading the active components.

Polycondensation of Hydroxyl Complexes

Beyond simple drying, the oven promotes a critical chemical reaction known as polycondensation.

Under the specific thermal condition of 105 °C, the aluminum and iron hydroxyl complexes within the liquid undergo further dehydration. This chemical bonding process increases the molecular weight and complexity of the flocculant, which is essential for its coagulation performance.

Structural Evolution and Stability

Formation of Polycrystalline Phases

The transition from liquid to solid results in a specific physical structure described as a polycrystalline phase coexistence structure.

This structural arrangement indicates that the material has moved past a simple amorphous state. The heat treatment ensures the material crystallizes in a way that locks in the chemical properties required for effective water treatment.

Ensuring Long-Term Viability

The conversion to a solid state addresses the instability often inherent in liquid flocculants.

By removing the liquid medium and finalizing the polymerization, the blast drying oven produces a material suitable for long-term storage. This prevents the degradation or settling that might occur if the PAFS remained in its liquid acid leach liquor form.

Understanding the Operational Advantages

Precision in Application

A primary reason for using the blast drying oven is to improve the usability of the final product.

Liquid flocculants can be difficult to dose accurately due to viscosity changes or concentration gradients. The solid flocculant produced by the oven allows for precise quantitative dosing, ensuring consistent performance in water treatment applications.

Critical Process Control

It is vital to adhere strictly to the temperature parameters established during this phase.

The primary reference highlights a constant condition of 105 °C. Deviating significantly from this temperature could fail to achieve the necessary polycondensation or potentially alter the desired polycrystalline structure.

Making the Right Choice for Your Goal

To maximize the effectiveness of your PAFS production, consider your specific end-use requirements:

- If your primary focus is long-term inventory management: Utilize the drying oven to fully convert the liquid to solid, as this stabilizes the material for extended storage without degradation.

- If your primary focus is process efficiency and accuracy: Ensure the material is dried to a solid state to enable precise quantitative dosing, eliminating the variability found in liquid handling.

Controlled thermal treatment is the bridge between a raw chemical intermediate and a reliable, industrial-grade flocculant.

Summary Table:

| Stage of Process | Mechanism | Outcome |

|---|---|---|

| Thermal Dehydration | Forced hot air circulation | Evaporation of moisture from polymerized liquid |

| Chemical Synthesis | Polycondensation at 105°C | Increased molecular weight and complex formation |

| Structural Evolution | Phase transformation | Formation of stable polycrystalline structures |

| Product Finalization | Solidification | Enhanced stability for storage and precise dosing |

Elevate Your Chemical Synthesis with KINTEK Precision

Transitioning from liquid intermediates to high-performance solid flocculants requires absolute thermal accuracy. At KINTEK, we understand that the difference between a successful reaction and a failed batch lies in the consistency of your equipment.

Backed by expert R&D and manufacturing, KINTEK offers a comprehensive range of high-performance lab equipment, including Muffle, Tube, Rotary, Vacuum, and CVD systems, along with specialized laboratory ovens. Our systems are fully customizable to meet the unique needs of your acid leach liquor processing and material synthesis research.

Ready to optimize your lab’s thermal processing? Contact us today to discover how our customizable high-temperature solutions can bring precision and stability to your chemical production.

References

- Zhilei Zhen, Haotian Ma. A Novel Method of Synthesizing Polymeric Aluminum Ferric Sulfate Flocculant and Preparing Red Mud-Based Ceramsite. DOI: 10.3390/ma17061239

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1200℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Vacuum Dental Porcelain Sintering Furnace for Dental Laboratories

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Vacuum Induction Melting Furnace

People Also Ask

- What is the purpose of a laboratory vacuum system in photocatalytic hydrogen evolution? Ensure Accurate Data Results

- What function does a PTFE liner serve in NiWO4 synthesis? Ensure Purity & Prevent Corrosion in Hydrothermal Reactors

- How does the use of a high-purity quartz crucible affect silicate inclusions? Master Industrial Melt Simulation

- Why is the use of high-purity alumina crucibles essential for the synthesis of Ni3In2Se2? | Precision Material Purity

- What role does a high-purity graphite mold play during the SPS of TiB2-SiC? Expert Material Densification Insights

- What is the function of ceramic alumina furnace tubes for Ti–Nb–Si alloys? Key Roles in Sintering & Purity

- What is the function of a vacuum system in PLD? Ensure High-Density, Pure Electrolyte Thin Films

- What are the main composition percentages of alumina tubes? Optimize Performance for High-Temperature Applications