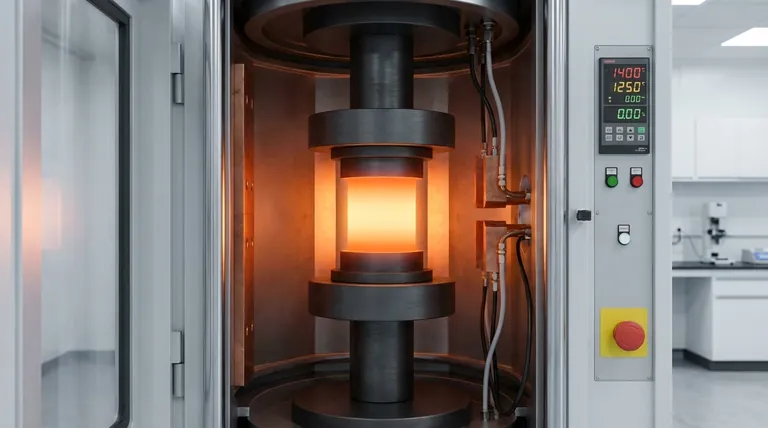

A high-purity graphite mold acts as a multifunctional reactor vessel that serves as the container, heating element, and pressure applicator simultaneously. In the Spark Plasma Sintering (SPS) of TiB2-SiC ceramics, it converts high-frequency pulsed current into intense thermal energy while transmitting massive mechanical force to densify the powder.

Core Takeaway The graphite mold is not a passive container; it is the active "engine" of the SPS process. By functioning simultaneously as an electrical resistor and a hydraulic piston, it creates the specific environment—temperatures exceeding 2000°C combined with high axial pressure—required to drive particle rearrangement and achieve near-theoretical density in refractory ceramics.

The Dual Role of Thermal and Electrical Conduction

Converting Current to Heat

In an SPS system, the graphite mold is the primary resistance heating element. High-frequency pulsed electric current flows directly through the conductive graphite.

Generating Joule Heat

Because graphite offers resistance to this electrical flow, it generates "Joule heat" within the mold walls itself. This thermal energy is immediately and directly conducted to the TiB2-SiC sample inside, allowing for extremely rapid heating rates that conventional sintering cannot match.

Withstanding Extreme Temperatures

TiB2-SiC ceramics require intense heat to sinter properly. The high-purity graphite mold is essential because it maintains structural integrity at temperatures exceeding 2000°C, a range where metal molds would melt or deform.

Mechanical Pressure and Densification

Transmitting Axial Force

While the mold heats the sample, it also serves as a mechanical transmission component. It endures thousands of Newtons of force from the system's hydraulic rams.

Acting as a Piston

The mold plunges act effectively as pistons, transferring this axial pressure (often up to or exceeding 30 MPa) directly into the ceramic powder.

Driving Particle Rearrangement

This mechanical pressure is critical for densification. It forces the powder particles to rearrange physically and helps overcome diffusion barriers, allowing the ceramic to reach full density at temperatures lower than would be required with heat alone.

Operational Trade-offs and Considerations

The Risk of Adhesion

At extreme temperatures, the ceramic sample can bond or stick to the graphite mold walls. To prevent this chemical interaction and ensure easy demolding, a layer of graphite paper is typically inserted between the powder and the mold.

Oxidation Sensitivity

While graphite is thermally robust, it oxidizes and degrades rapidly in air at high temperatures. Therefore, the SPS process must occur within a vacuum or an inert gas atmosphere to protect the structural integrity of the mold.

Making the Right Choice for Your Goal

To maximize the effectiveness of graphite tooling in your SPS process, consider these priorities:

- If your primary focus is Maximum Density: Ensure the mold design has sufficient wall thickness to withstand the maximum axial pressure (30+ MPa) without fracture during the hold time.

- If your primary focus is Sample Purity: Utilize high-quality graphite paper barriers to prevent carbon diffusion from the mold into the TiB2-SiC matrix.

The success of your sintering run depends entirely on the graphite mold's ability to maintain uniform pressure and conductivity under extreme thermal stress.

Summary Table:

| Function | Description | Key Benefit in SPS |

|---|---|---|

| Heating Element | Converts pulsed current into Joule heat via electrical resistance. | Enables rapid heating rates and temperatures >2000°C. |

| Pressure Applicator | Transmits hydraulic axial force (up to 30+ MPa) to the powder. | Drives particle rearrangement and lowers sintering temperature. |

| Reaction Vessel | High-purity structural container for refractory materials. | Maintains integrity under extreme thermal and mechanical stress. |

| Purity Barrier | Utilizes graphite paper to prevent chemical bonding/sticking. | Ensures clean demolding and prevents carbon contamination. |

Optimize Your Advanced Ceramics Sintering with KINTEK

Precision in SPS processing starts with the right equipment and tooling. Backed by expert R&D and manufacturing, KINTEK offers a comprehensive range of Muffle, Tube, Rotary, Vacuum, and CVD systems, all fully customizable to meet your unique laboratory and production needs. Whether you are sintering TiB2-SiC composites or developing next-generation refractories, our high-temperature solutions ensure uniform heating and reliable performance.

Ready to achieve superior material density? Contact KINTEK today to discuss your custom furnace requirements!

References

- German Alberto Barragán De Los Rios, Patricia Fernández‐Morales. Numerical Simulation of Aluminum Foams by Space Holder Infiltration. DOI: 10.1007/s40962-024-01287-8

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Spark Plasma Sintering SPS Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- 9MPa Air Pressure Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

People Also Ask

- Why is a graphite crucible preferred for SiNQ synthesis? Master Heat Management in Magnesiothermic Reduction

- Why is a laboratory drying oven or heating plate necessary for Ba7Nb4MoO20? Optimize Slurry Synthesis Results

- Why is the laboratory water circulating vacuum pump particularly suitable for labs? Boost Efficiency and Safety in Your Lab

- What are the primary functions of a self-preheating heat exchanger? Maximize Thermal Efficiency in Double-P Tubes

- Why is a vacuum drying oven necessary for Al2O3/TiC ceramic powders? Ensure Purity and Prevent Agglomeration

- What is the standard procedure for using a laboratory precision oven to determine the Total Solids (TS) of biomass?

- Why is a vacuum suction system required during the exhaust stage of rice straw-based charcoal carbonization?

- What are quartz tubes used for? Essential for High-Temperature, High-Purity Applications