In essence, quartz tubes are high-performance containers used in scientific and industrial processes that demand extreme temperature stability, chemical purity, and often, optical transparency. They primarily function as reaction chambers in laboratory furnaces and are indispensable in the manufacturing of semiconductors, where preventing contamination is paramount.

A quartz tube is not merely a piece of glass; it is a precisely engineered environment. Its value lies in its unique ability to remain inert and stable under conditions that would cause other materials to fail, making it a critical component for high-purity, high-temperature applications.

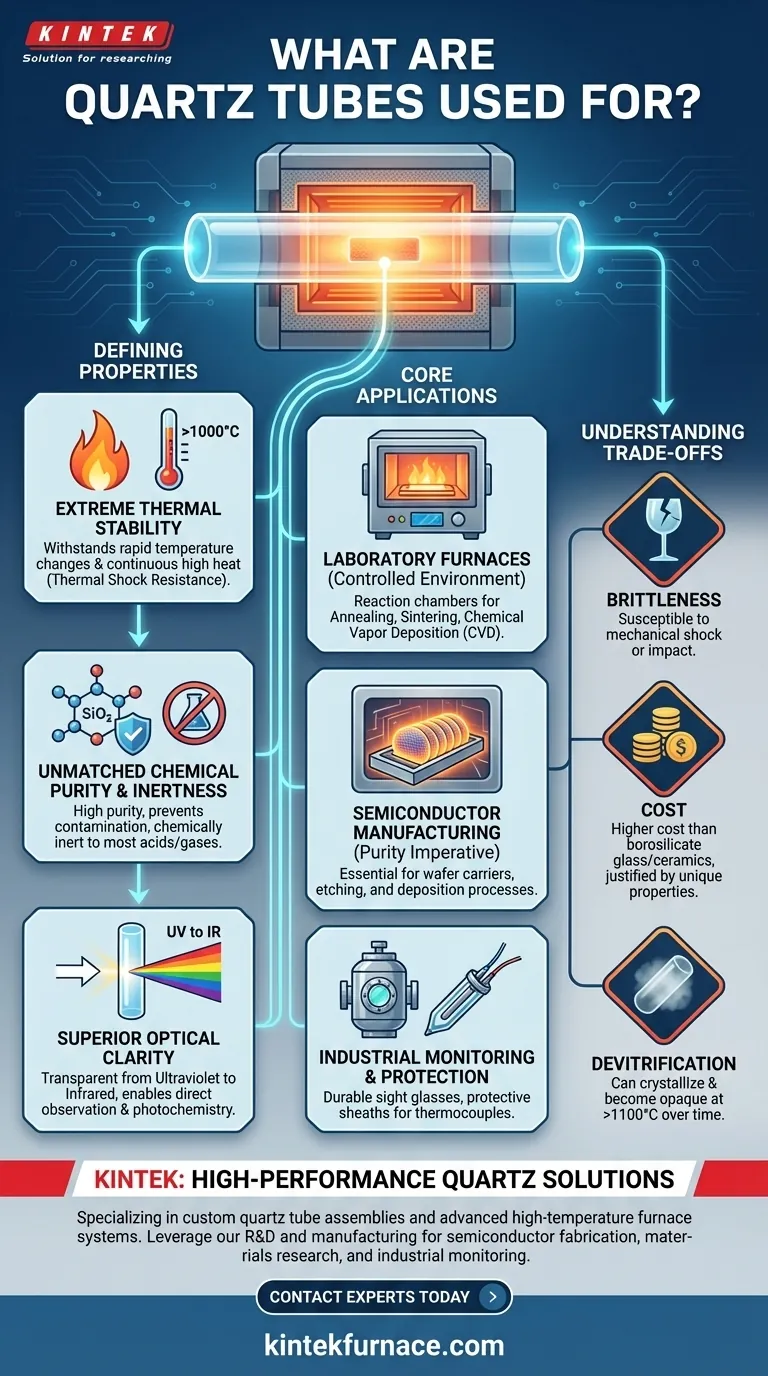

The Defining Properties of Quartz

To understand the applications of quartz, we must first understand the material itself. Its use is not arbitrary; it is a direct result of a powerful combination of physical and chemical properties.

Extreme Thermal Stability

Quartz glass possesses an exceptionally low coefficient of thermal expansion. This means it can withstand rapid temperature changes without cracking—a phenomenon known as thermal shock resistance.

It maintains its structural integrity at continuous temperatures exceeding 1000°C, making it the default choice for many high-temperature processes.

Unmatched Chemical Purity & Inertness

Quartz tubes are valued for their high purity, typically composed of silicon dioxide (SiO₂) with minimal impurities. This purity is critical in applications like semiconductor manufacturing, where even trace contaminants can ruin a microchip.

Furthermore, quartz is chemically inert and does not react with most acids, compounds, or process gases, ensuring that the experiment or process remains uncontaminated.

Superior Optical Clarity

Unlike many ceramics, quartz is transparent across a wide spectrum of light, from the ultraviolet (UV) to the infrared (IR).

This optical clarity allows for direct observation of processes inside the tube. It also enables applications that use light to initiate reactions (photochemistry) or for in-situ analysis.

Core Applications in Science and Industry

These properties make quartz tubes essential in a range of highly technical fields.

Laboratory Furnaces: The Controlled Environment

The most common application is as a reaction chamber within a tube furnace. By placing materials inside a quartz tube and sealing the ends with flanges, a tightly controlled atmosphere can be created.

This setup is fundamental for processes like annealing (heat-treating to alter material properties), sintering (creating a solid mass from powder by heat), and chemical vapor deposition (CVD).

Semiconductor Manufacturing: The Purity Imperative

The electronics industry relies heavily on quartz. Its high purity prevents contamination of silicon wafers during the manufacturing of integrated circuits.

Quartz is used to create wafer boats and carriers that hold silicon wafers during high-temperature treatments. It also forms the chambers for etching and deposition processes where chemical inertness is vital.

Industrial Monitoring & Protection

In broader industrial settings, quartz serves several practical functions. Its durability and clarity make it ideal for sight glasses in high-pressure or high-temperature vessels.

Because it withstands heat and is an excellent electrical insulator, it is frequently used as a protective sheath for thermocouples, shielding the sensitive sensor from a harsh environment without distorting the temperature reading.

Understanding the Trade-offs

While exceptionally useful, quartz is not without its limitations. A true technical assessment requires acknowledging its trade-offs.

Brittleness and Mechanical Shock

Like any glass, quartz is brittle. It is susceptible to failure from mechanical shock or impact. In environments with significant vibration or risk of physical contact, metallic alloys may be a more robust, albeit less pure, choice.

Cost

High-purity quartz is more expensive than standard borosilicate glass or many ceramic alternatives. Its use is typically justified only when its unique thermal and chemical properties are a strict requirement.

Devitrification

At very high temperatures (typically above 1100°C) and over long periods, quartz can begin to crystallize, a process called devitrification. This causes it to become opaque and more brittle, eventually requiring replacement. The presence of surface contaminants can accelerate this process.

Making the Right Choice for Your Application

Selecting the correct material is critical for procedural success, safety, and budget.

- If your primary focus is high-temperature processing in a controlled atmosphere: Quartz is the default and often best choice for processes like annealing or CVD below 1100°C.

- If your primary focus is ultra-high purity: For semiconductor fabrication, trace element analysis, or pharmaceutical research, the inertness of quartz is non-negotiable.

- If your primary focus is mechanical durability or extreme temperatures (>1200°C): You should consider alternatives like high-purity alumina ceramic tubes, which offer higher temperature resistance but are opaque.

Ultimately, selecting a quartz tube is a decision to prioritize purity and stability in the most demanding thermal and chemical environments.

Summary Table:

| Key Property | Key Application |

|---|---|

| Extreme Thermal Stability (>1000°C) | Laboratory Tube Furnaces (Annealing, CVD) |

| High Chemical Purity & Inertness | Semiconductor Wafer Processing |

| Superior Optical Clarity (UV to IR) | Photochemistry, In-situ Analysis |

| Durability & Electrical Insulation | Thermocouple Sheaths, Sight Glasses |

Need a high-performance quartz tube solution for your demanding application?

KINTEK specializes in providing advanced high-temperature furnace systems, including custom quartz tube assemblies. Leveraging our exceptional R&D and in-house manufacturing, we deliver the purity, thermal stability, and optical clarity your processes require—whether for semiconductor fabrication, materials research, or industrial monitoring.

Our product line, including Tube Furnaces, CVD/PECVD Systems, and more, is complemented by strong deep customization capabilities to precisely meet your unique experimental and production needs.

Contact our experts today to discuss how we can enhance your lab's capabilities with a tailored quartz tube solution.

Visual Guide

Related Products

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Vertical Laboratory Quartz Tube Furnace Tubular Furnace

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

People Also Ask

- What happens to convective and radiative heat transfer effects at high furnace gas temperatures? Radiation Dominates for Superior Heating

- What factors should be considered when purchasing a quartz tube furnace? Ensure Reliable High-Temperature Processing

- How should a quartz tube furnace be cleaned? Essential Steps for Safe, Contamination-Free Maintenance

- What is a Quartz Tube Furnace and what is its primary function? Essential for Real-Time Material Observation

- How does the work process of a quartz tube furnace typically proceed? Master Precision Heating for Advanced Materials