In a laboratory setting, efficiency and versatility are non-negotiable. The water circulating vacuum pump is uniquely suited for this environment because it integrates a compact, mobile design with the dual functions of creating a vacuum and providing cooling water. This multi-purpose approach saves space, energy, and water, making it a highly practical tool for common lab procedures.

This pump is more than just a vacuum source; it is a resource-efficient utility designed for the specific constraints of a modern lab. Its core advantage lies in using a simple, robust water-based mechanism to perform multiple tasks—vacuum generation and cooling—quietly and safely, even when handling corrosive vapors.

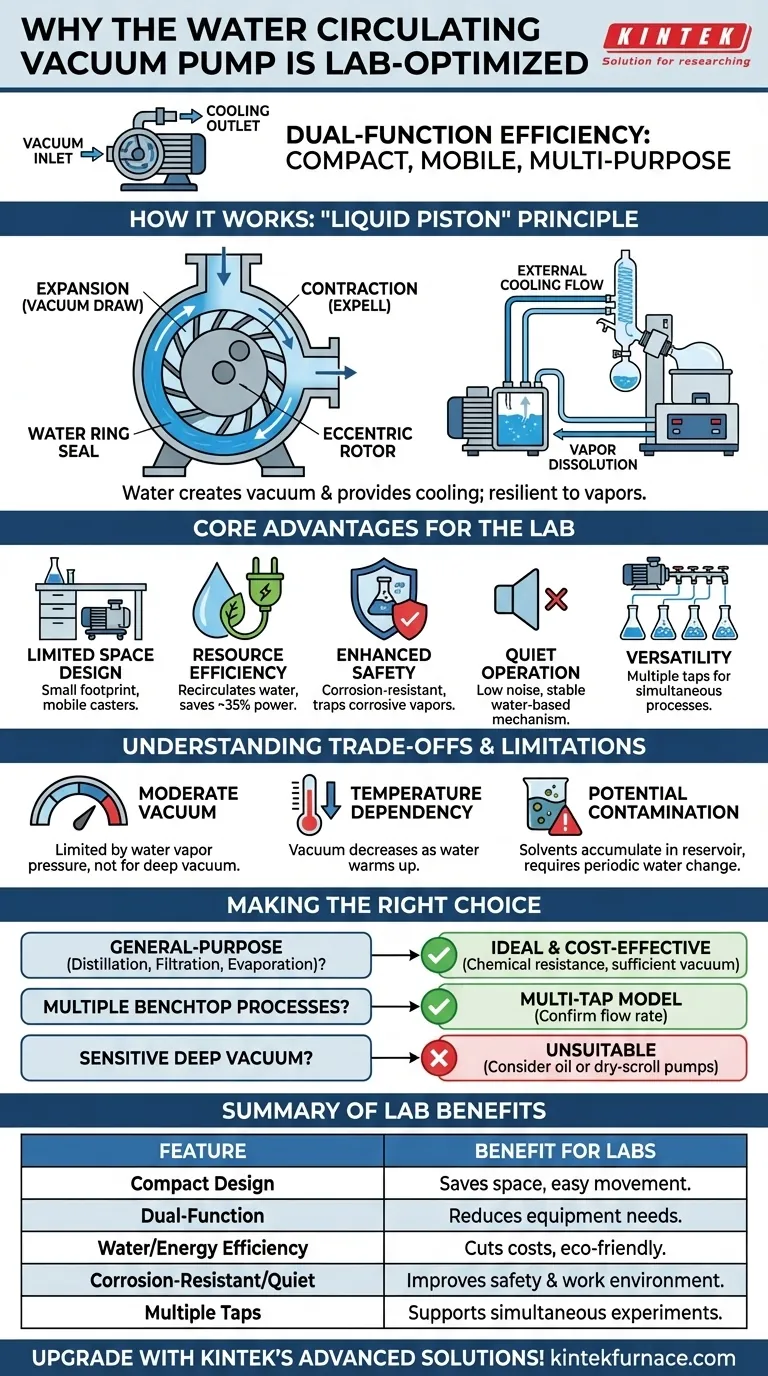

How It Works: The "Liquid Piston" Principle

The ingenuity of the water circulating vacuum pump lies in its use of a readily available fluid—water—to perform mechanical work. This design choice leads to several of its most significant laboratory advantages.

Using Water to Create a Vacuum

At its heart, the pump operates using an eccentric rotor with blades spinning inside a casing. Centrifugal force creates a ring of water that seals against the casing wall.

Because the rotor is off-center, the space between the blades and the water ring continuously expands and contracts. This expansion draws gas in (creating a vacuum), and the subsequent contraction compresses and expels the gas. This process effectively uses a "liquid piston" of water, which is far more resilient to chemical vapors than the mechanical parts of a dry pump.

The Dual-Function Advantage

The "circulating water" in its name is a key feature. This same body of water used to generate the vacuum can also be circulated externally.

This allows the pump to simultaneously provide cooling water for reaction equipment, such as the condenser on a rotary evaporator or a distillation apparatus. A single piece of equipment thus serves two essential lab functions.

Core Advantages for the Laboratory Environment

A water circulating pump is not the most powerful vacuum available, but its design is optimized for the daily realities of lab work.

Designed for Limited Space

These pumps are engineered with a small footprint and are often equipped with casters. This makes them easy to move between workstations or store under a bench, a critical feature in crowded lab spaces.

Resource Efficiency: Water and Power

By continuously recirculating a small reservoir of water, the pump avoids the massive water waste associated with single-pass water aspirators. Furthermore, they are designed for energy efficiency, saving more than 35% in electricity compared to other vacuum pump types.

Enhanced Safety with Corrosive Vapors

Many lab procedures, like evaporation and distillation, pull solvent vapors into the vacuum line. In a water circulating pump, these vapors dissolve into the water reservoir, preventing them from damaging the pump's mechanical parts or being exhausted into the lab's atmosphere. The pump itself is built with corrosion-resistant materials and a sealed motor to protect it from this harsh environment.

Quiet and Stable Operation

The use of water as the working medium, often combined with a specialized fluid muffler, makes these pumps significantly quieter than dry scroll or oil-sealed rotary vane pumps. This reduces ambient noise in the lab, creating a better working environment.

Versatility for Multiple Processes

Many models come with two or four outlet taps. This allows a single pump to provide a vacuum for multiple experimental setups simultaneously, such as two separate filtration stations or rotary evaporators, maximizing equipment utilization.

Understanding the Trade-offs and Limitations

To use this equipment effectively, it is crucial to understand its limitations. A water pump is a specific tool for a specific job, not a universal solution.

Vacuum Level is Moderate

The ultimate vacuum a water pump can achieve is limited by the vapor pressure of the water itself. This means it cannot produce the deep vacuum required for high-vacuum applications like freeze-drying or molecular distillation.

Temperature Dependency

The vacuum level is directly dependent on the water's temperature—colder water produces a better (lower pressure) vacuum. On a hot day or after prolonged use, the water in the reservoir will warm up, and the pump's performance will decrease.

Potential for Contamination

Solvents and acids pulled into the vacuum will accumulate in the water reservoir. This can reduce vacuum performance and requires that the water be changed periodically to maintain efficiency and prevent cross-contamination between experiments.

Making the Right Choice for Your Application

Selecting the correct vacuum source depends entirely on your experimental needs.

- If your primary focus is general-purpose distillation, filtration, or rotary evaporation: A water circulating pump is an ideal and cost-effective choice due to its chemical resistance and sufficient vacuum level.

- If your primary focus is running multiple benchtop processes at once: Seek out a model with multiple taps (2- or 4-port) and confirm its flow rate can support all connected applications.

- If your primary focus is achieving a very deep vacuum for sensitive applications: This pump is unsuitable; you must consider a two-stage rotary vane (oil) pump or a dry-scroll pump instead.

By understanding its principles and limitations, you can leverage the water circulating pump as a robust and efficient workhorse for your laboratory's core processes.

Summary Table:

| Feature | Benefit for Labs |

|---|---|

| Compact, mobile design | Saves space and allows easy movement in crowded labs |

| Dual-function (vacuum and cooling) | Reduces equipment needs and enhances versatility |

| Water and energy efficiency | Cuts costs by recirculating water and using less power |

| Corrosion-resistant and quiet operation | Improves safety and reduces noise for a better work environment |

| Multiple outlet taps | Supports simultaneous experiments, increasing productivity |

Upgrade your lab's efficiency with KINTEK's advanced solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with high-temperature furnace systems like Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we precisely meet your unique experimental requirements. Contact us today to discuss how our products can enhance your lab's performance and reliability!

Visual Guide

Related Products

- Ultra Vacuum Electrode Feedthrough Connector Flange Power Lead for High Precision Applications

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

People Also Ask

- What role does the planetary ball mill play in LLZO mixing? Unlock High-Performance Solid-State Electrolyte Synthesis

- How many taps does the water circulating vacuum pump have? Choose the Right Model for Your Lab

- What is the advantage of the circulating water multifunctional vacuum pump being one machine for multiple purposes? Streamline Lab Work Efficiently

- Why are high-purity alumina crucibles required for high-temperature melting studies of sintering ores? Expert Insights

- Why is a high-performance vacuum pumping system required for DLC coatings? Achieve 3.0 x 10^-5 Pa Purity

- What are the primary functions of the vacuum pump system and inert gases? Achieve High-Purity Atomization

- What are the main components of a Laboratory Furnace? Essential Parts for Precise High-Temperature Processing

- What are the key advantages of using quartz tubes in high-temperature applications? Achieve Unmatched Thermal Stability and Purity