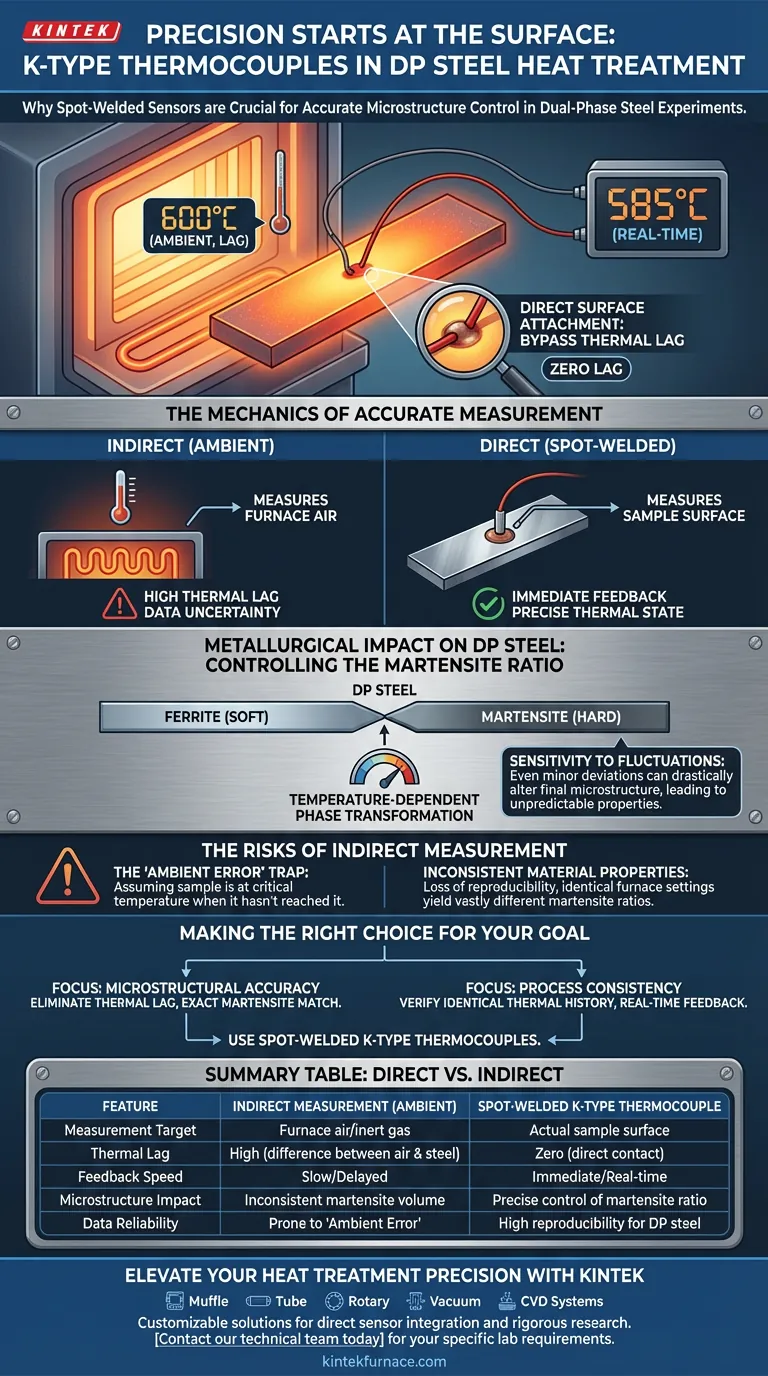

Precision starts at the surface. Spot-welded K-type thermocouples are indispensable in Dual-Phase (DP) steel experiments because they attach directly to the sample, measuring the material's actual temperature rather than the surrounding environment. This provides the real-time monitoring required to maintain strict heat treatment parameters and eliminate the guesswork associated with ambient furnace sensors.

In the processing of DP steel, even minor temperature fluctuations can drastically alter the final martensite ratio. Direct surface monitoring is the only way to secure the precise feedback needed to guarantee consistent microstructural evolution.

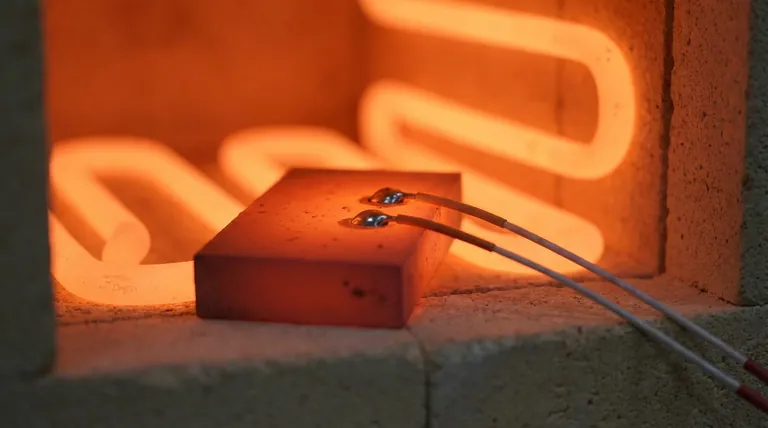

The Mechanics of Accurate Measurement

Direct Surface Attachment

Standard furnace thermocouples measure the air or inert gas inside the chamber, not the sample itself. By using spot-welded K-type thermocouples, you bypass the thermal lag between the heating element and the specimen. This ensures the data reflects the exact thermal state of the steel at any given second.

Real-Time Monitoring

Heat treatment requires adherence to specific heating rates and soak times. Spot-welded sensors provide immediate feedback, allowing for dynamic adjustments during the cycle. This capability is critical for verifying that the programmed parameters align with the physical reality of the sample.

The Metallurgical Impact on DP Steel

Controlling the Martensite Ratio

The mechanical properties of Dual-Phase steel are defined by the balance between soft ferrite and hard martensite. This martensite ratio is established during the annealing phase. Because this phase transformation is temperature-dependent, accurate thermal control is non-negotiable.

Sensitivity to Fluctuations

The primary reference highlights that minor temperature fluctuations can significantly impact the final microstructure. If the temperature deviates even slightly from the target, the volume fraction of martensite will change. This leads to unpredictable mechanical properties and failed experiments.

The Risks of Indirect Measurement

The "Ambient Error" Trap

Relying on indirect temperature measurement (non-contact) introduces uncertainty regarding the sample's core temperature. Without the strict feedback from a spot-welded unit, you risk assuming the sample has reached critical temperature when it has not.

Inconsistent Material Properties

The trade-off for neglecting direct contact monitoring is a loss of reproducibility. Without precise data to confirm that heat treatment parameters are strictly maintained, identical furnace settings may yield samples with vastly different martensite ratios and performance characteristics.

Making the Right Choice for Your Goal

To ensure your DP steel experiments yield valid, reproducible data, you must prioritize direct measurement.

- If your primary focus is Microstructural Accuracy: Use spot-welded thermocouples to eliminate thermal lag, ensuring the martensite ratio exactly matches your theoretical design.

- If your primary focus is Process Consistency: Rely on the real-time feedback from these sensors to verify that every sample experiences the exact same thermal history, regardless of furnace fluctuations.

Direct contact measurement is not just a monitoring tool; it is the control mechanism for material quality.

Summary Table:

| Feature | Indirect Measurement (Ambient) | Spot-Welded K-Type Thermocouple |

|---|---|---|

| Measurement Target | Furnace air/inert gas | Actual sample surface |

| Thermal Lag | High (difference between air & steel) | Zero (direct contact) |

| Feedback Speed | Slow/Delayed | Immediate/Real-time |

| Microstructure Impact | Inconsistent martensite volume | Precise control of martensite ratio |

| Data Reliability | Prone to "Ambient Error" | High reproducibility for DP steel |

Elevate Your Heat Treatment Precision with KINTEK

Don't let minor temperature fluctuations compromise your Dual-Phase steel microstructure. KINTEK provides the high-performance laboratory solutions required for rigorous metallurgical research. Backed by expert R&D and manufacturing, we offer Muffle, Tube, Rotary, Vacuum, and CVD systems, all fully customizable to accommodate direct sensor integration and your unique experimental needs.

Ensure absolute process consistency and microstructural accuracy in every cycle. Contact our technical team today to find the perfect high-temperature furnace for your lab's specific requirements.

Visual Guide

References

- Pedram Dastur, Claire Davis. Development of a High Ductility DP Steel Using a Segregation Neutralization Approach: Benchmarked Against a Commercial Dual Phase Steel. DOI: 10.1007/s11661-024-07427-3

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Molybdenum Disilicide MoSi2 Thermal Heating Elements for Electric Furnace

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- HFCVD Machine System Equipment for Drawing Die Nano Diamond Coating

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Ultra-High Vacuum Flange Aviation Plug Glass Sintered Airtight Circular Connector for KF ISO CF

People Also Ask

- What is the function of a graphite crucible in synthesis? Ensure Purity in Sn0.50Ag0.25Bi0.25Se0.50Te0.50 Production

- What multiple roles do high-purity, high-strength graphite molds play in the Spark Plasma Sintering (SPS) process?

- What is the purpose of using a high-purity quartz boat? Ensure Sample Purity in TiO2@C High-Temp Annealing

- How does a vacuum pump facilitate the synthesis process of rare earth-based halide electrolytes? Boost Chemical Purity

- What is the significance of using a laboratory electric thermostatic blast drying oven for biomass briquette moisture control?

- Why is selecting the right laboratory furnace important for ceramic sintering? Ensure Precise Control for Superior Ceramic Properties

- Why is a molybdenum crucible considered an ideal choice for quartz melting? High-Purity Solutions at 2000°C

- Why must high-pressure microwave reaction vessels maintain excellent sealing performance? Ensure Carbon Synthesis Success