In ceramic processing, the laboratory furnace is not merely a source of heat; it is the single most critical instrument for controlling the material's final properties. Selecting the right furnace is paramount because it directly dictates the ceramic's density, strength, and microstructure by precisely managing the transformation from a fragile powder compact into a robust, solid component.

The core challenge of sintering is flawlessly executing a specific time-temperature-atmosphere profile. The right furnace provides the necessary precision and control, while the wrong one introduces variability that leads to inconsistent results, failed parts, and wasted resources.

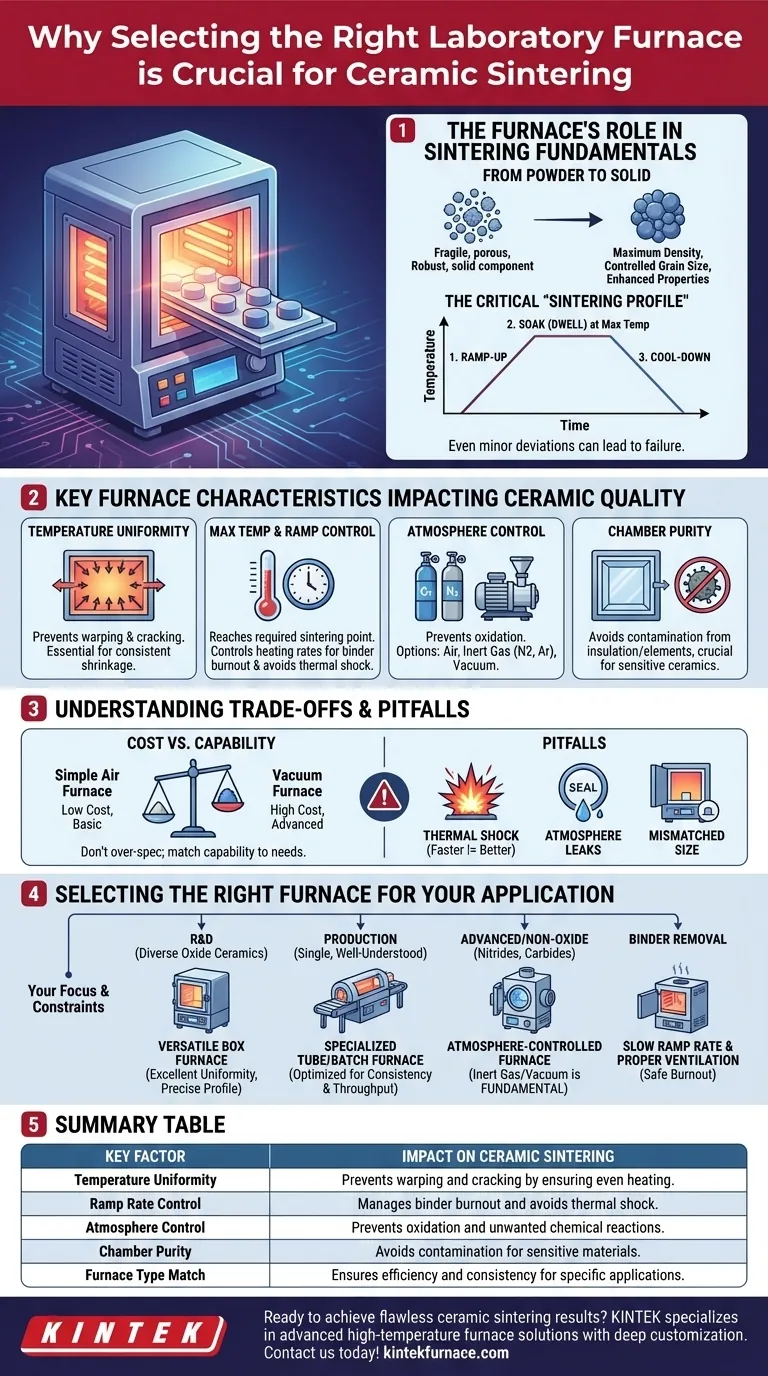

The Furnace's Role in Sintering Fundamentals

To understand why furnace selection is so critical, we must first understand the sintering process itself. It is a delicate thermal treatment that requires absolute control.

From Powder to Solid

Sintering is the process of bonding particles together into a solid mass using heat, but without melting them. At high temperatures, atoms diffuse across the boundaries of the particles, fusing them together and gradually eliminating the pores between them.

The goal is to achieve maximum density with a controlled grain size, as these factors determine the final mechanical and physical properties of the ceramic part.

The Critical "Sintering Profile"

Success depends on the furnace's ability to accurately follow a pre-defined heating recipe, known as the sintering profile. This profile has three main stages:

- Ramp-up: The rate at which the temperature increases.

- Soak (or Dwell): The time the material is held at the maximum sintering temperature.

- Cool-down: The rate at which the material is cooled back to room temperature.

Even minor deviations from this planned profile can fundamentally alter the final ceramic and lead to failure.

Key Furnace Characteristics That Impact Ceramic Quality

The "best" furnace is the one whose characteristics perfectly match the requirements of your specific ceramic material and desired outcome.

Temperature Uniformity

This is arguably the most important factor. Temperature uniformity refers to the furnace's ability to maintain the same temperature throughout the entire heating chamber.

Hot or cold spots cause different parts of the ceramic to shrink at different rates. This creates internal stresses that can lead to warpage, cracking, and a complete loss of dimensional accuracy.

Maximum Temperature and Ramp Rate Control

The furnace must be able to comfortably reach a temperature above the required sintering point for your material.

Equally important is its ability to control the ramp rate. Some processes require a slow, controlled heating to burn out binders without causing defects, while others may benefit from a faster ramp to the soak temperature. A lack of precise ramp control limits your processing window.

Atmosphere Control

Many ceramics react with oxygen at high temperatures, a process known as oxidation. This is often detrimental to the final properties. Atmosphere control is the furnace's ability to maintain a specific gaseous environment.

- Air: Suitable for many oxide ceramics (like alumina or zirconia). These are the simplest and most common furnaces.

- Inert Gas: Non-oxide ceramics (like silicon nitride) or oxygen-sensitive materials require an inert atmosphere (e.g., Argon, Nitrogen) to prevent unwanted chemical reactions.

- Vacuum: A vacuum environment is the ultimate form of atmosphere control, removing reactive gases to an extremely high degree, which is essential for sintering certain advanced materials and metals.

Chamber Contamination

The materials used to construct the furnace's heating chamber and insulation can be a source of contamination. At high temperatures, elements can vaporize from insulation or heating elements and deposit onto your ceramic part, altering its chemistry and performance.

A furnace with high-purity alumina insulation and non-contaminating elements is crucial for sensitive electronic or medical-grade ceramics.

Understanding the Trade-offs and Pitfalls

Choosing a furnace involves balancing capability with cost and complexity. Awareness of the common trade-offs is key to making an informed decision.

Cost vs. Capability

A simple air furnace capable of reaching 1200°C is significantly less expensive than a vacuum furnace rated for 1800°C. Do not over-spec your furnace. Buying a high-end furnace with capabilities you will never use is an inefficient use of capital.

The Myth of "Faster is Better"

Rapid heating and cooling rates can induce thermal shock, causing catastrophic cracking in the ceramic part. The ability to cool slowly and in a controlled manner is often just as important as the ability to heat up.

Neglecting Atmosphere Purity

When using an inert gas furnace, even a small leak in a fitting or door seal can introduce enough oxygen to ruin an entire batch. Ensuring the integrity of the furnace's seals and gas delivery system is non-negotiable for atmosphere-controlled processes.

Mismatching Furnace Size to Part Size

Using a very large production furnace to sinter a single, small research sample is highly inefficient. It wastes enormous amounts of energy and time, and achieving tight temperature uniformity for a small object in a large chamber can be more difficult.

Selecting the Right Furnace for Your Application

Your choice should be guided by your material, your end goal, and your operational constraints.

- If your primary focus is R&D with diverse oxide ceramics: Choose a versatile box furnace with excellent temperature uniformity and precise ramp/soak programming.

- If your primary focus is production of a single, well-understood ceramic: A specialized tube or batch furnace optimized for that exact sintering profile will deliver the best consistency and throughput.

- If your primary focus is advanced or non-oxide ceramics (nitrides, carbides): An atmosphere-controlled furnace (inert gas or vacuum) is not a luxury; it is a fundamental requirement.

- If you are working with binders that must be removed: Prioritize a furnace with slow ramp rate control and proper ventilation to safely and completely burn out these additives before densification begins.

Ultimately, the furnace is a direct partner in your materials development, and choosing the right one is the first step toward achieving repeatable success.

Summary Table:

| Key Factor | Impact on Ceramic Sintering |

|---|---|

| Temperature Uniformity | Prevents warping and cracking by ensuring even heating |

| Ramp Rate Control | Manages binder burnout and avoids thermal shock |

| Atmosphere Control | Prevents oxidation and unwanted chemical reactions |

| Chamber Purity | Avoids contamination for sensitive materials |

| Furnace Type Match | Ensures efficiency and consistency for specific applications |

Ready to achieve flawless ceramic sintering results? At KINTEK, we specialize in providing advanced high-temperature furnace solutions tailored to your unique needs. Leveraging our exceptional R&D and in-house manufacturing, we offer a diverse product line including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. With strong deep customization capabilities, we ensure precise control over temperature, atmosphere, and ramp rates to meet your exact experimental requirements. Don't let furnace variability hold you back—contact us today to discuss how our solutions can enhance your lab's efficiency and deliver consistent, high-quality ceramics!

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

People Also Ask

- How does a vertical tube furnace achieve precise temperature control? Unlock Superior Thermal Stability for Your Lab

- What safety measures are essential when operating a lab tube furnace? A Guide to Preventing Accidents

- What are the key operational considerations when using a lab tube furnace? Master Temperature, Atmosphere & Safety

- Why is a tube furnace utilized for the heat treatment of S/C composite cathode materials? Optimize Battery Stability

- What is an example of a material prepared using a tube furnace? Master Precise Material Synthesis