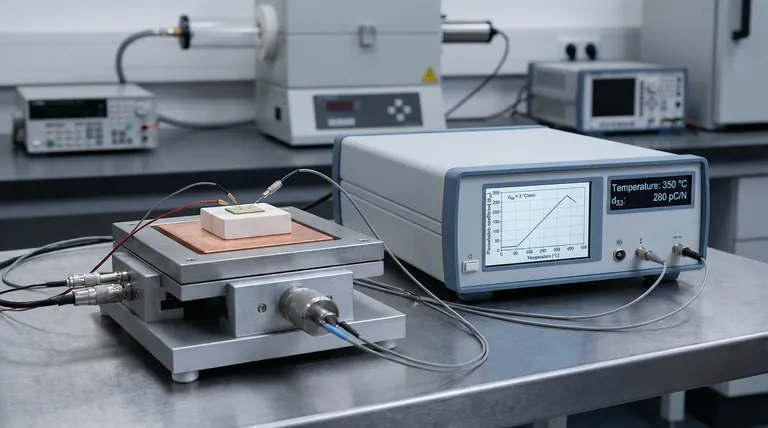

A high-temperature heating stage serves as a precision testing environment designed to quantify how piezoelectric properties degrade or evolve under thermal stress. When integrated with testing instruments, it maintains a controlled heating rate (such as 3 °C/min) from room temperature to over 400 °C, allowing researchers to measure the piezoelectric coefficient ($d_{33}$) directly against annealing temperature.

The core function of this equipment is to simulate operational thermal stress to verify material limits. By isolating the exact temperature at which piezoelectric performance declines, it provides the critical data needed to validate ceramics for high-temperature sensor applications.

The Mechanics of Thermal Characterization

Controlled Thermal Ramping

The primary value of a high-temperature heating stage is its ability to provide a linear, consistent rise in temperature.

Unlike a simple oven, this stage integrates with measurement tools to apply a specific heating rate, often set at 3 °C/min. This slow, steady ramp ensures the ceramic sample is heated evenly, preventing thermal shock from skewing data.

Tracking the Piezoelectric Coefficient ($d_{33}$)

As the temperature rises from room temperature toward 400 °C, the instrument continuously monitors the material's performance.

The key metric observed is the $d_{33}$ coefficient, which indicates the material's charge sensitivity to applied force. By plotting $d_{33}$ against the annealing temperature, engineers can identify the "depoling" temperature—the point where the material loses its piezoelectric properties and becomes unusable for sensors.

Distinguishing Characterization from Manufacturing

It is critical to distinguish the heating stage used for testing from the equipment used for manufacturing.

Testing vs. Densification

The high-temperature heating stage discussed above is a characterization tool operating generally up to 400 °C.

In contrast, the sintering furnace is a manufacturing tool that operates at much higher temperatures, typically between 1050 °C and 1150 °C.

The Role of Microstructure

While the heating stage tests the final performance, the sintering furnace creates the material's structure.

Through diffusion mechanisms at extreme temperatures, the sintering furnace drives grain growth and pore elimination. This process establishes the density and grain size distribution that the heating stage will later evaluate for thermal stability.

Understanding the Trade-offs

Simulation vs. Real-world Application

While a heating stage effectively characterizes thermal stability, it is a controlled simulation.

It applies heat externally and uniformly, which may not perfectly replicate rapid thermal cycling or uneven heating gradients found in dynamic, real-world engine or industrial sensor environments.

Temperature Limits

Most characterization heating stages are limited to the 400 °C range, which covers the operating limits of many standard piezoelectric materials.

However, if you are developing ultra-high-temperature ceramics intended to survive conditions near their Curie point (which can exceed this range), standard heating stages may not reach the temperatures required to observe total failure.

Making the Right Choice for Your Goal

To ensure you are gathering the correct data for your piezoelectric project, consider your immediate objective:

- If your primary focus is validating sensor reliability: Utilize the high-temperature heating stage to determine the maximum operating temperature before the $d_{33}$ coefficient degrades.

- If your primary focus is improving material density: Focus on optimizing the sintering furnace profile (1050–1150 °C) to enhance grain growth and eliminate internal pores.

Ultimately, the heating stage acts as the final quality gate, ensuring the microstructure created during sintering can withstand the thermal demands of the real world.

Summary Table:

| Feature | High-Temperature Heating Stage | Sintering Furnace |

|---|---|---|

| Primary Function | Performance Characterization (Testing) | Material Manufacturing (Densification) |

| Temperature Range | RT to ~400 °C | 1050 °C to 1150 °C |

| Key Metric Measured | Piezoelectric Coefficient ($d_{33}$) | Grain Growth & Porosity |

| Heating Dynamics | Precision Ramping (e.g., 3 °C/min) | High-Temp Diffusion & Sintering |

| Application Goal | Validating Sensor Thermal Limits | Optimizing Microstructure & Density |

Elevate Your Material Research with KINTEK

Precise thermal characterization is the difference between sensor failure and field reliability. Backed by expert R&D and manufacturing, KINTEK offers a comprehensive range of Muffle, Tube, Rotary, Vacuum, and CVD systems, along with specialized lab high-temp furnaces. Whether you are optimizing sintering profiles at 1150 °C or validating thermal stability for piezoelectric ceramics, our customizable solutions are designed to meet your unique laboratory needs.

Ready to achieve superior thermal precision? Contact us today to discuss how our high-temperature systems can empower your next breakthrough.

References

- Novel high-<i>T</i>C piezo-/ferroelectric ceramics based on a medium-entropy morphotropic phase boundary design strategy. DOI: 10.1063/5.0244768

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Molybdenum Disilicide MoSi2 Thermal Heating Elements for Electric Furnace

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Laboratory Muffle Oven Furnace with Bottom Lifting

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

People Also Ask

- What is the general ambient temperature limit for water circulating vacuum pumps? Ensure Peak Performance and Avoid Damage

- What is the function of a high-precision constant temperature oven in LIG composite curing? Achieve Perfect Stability

- What is the function of BN coating in Y2O3-YAM hot-press sintering? Ensure Purity and Smooth Mold Release

- Why is it necessary to use alumina or ceramic crucibles during the high-temperature evaporation of magnesium? Ensure Purity and Process Integrity

- What role does a rotary evaporator play in microalgae-based nanomaterials? Protect Bio-Reductive Activity for Synthesis

- Why is high-purity tantalum foil used when melting Ce2(Fe, Co)17 alloy? Protect Your Rare-Earth Materials

- What is the impact of gas flow meters on catalyst synthesis? Ensure Phase Purity and Precision in (NiZnMg)MoN Production

- What is the specific purpose of using a graphite crucible equipped with a plug during the melting process of Mg3Sb2?