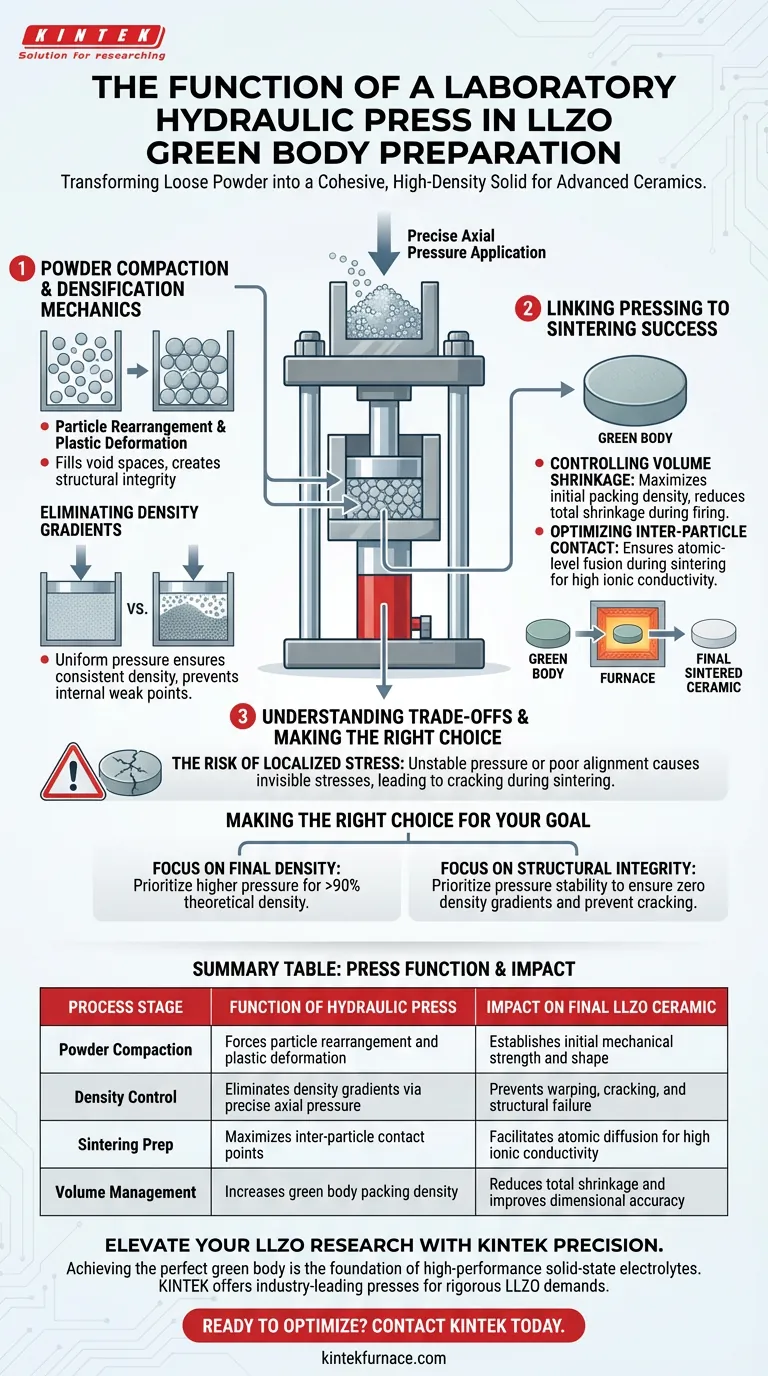

The primary function of a laboratory hydraulic press in LLZO preparation is to transform loose powder into a solid, cohesive form known as a "green body." By applying precise axial pressure within a mold, the press forces the powder particles to rearrange and undergo plastic deformation. This creates a compact shape with sufficient mechanical strength to withstand handling prior to the high-temperature sintering process.

The quality of the green body directly dictates the success of the final ceramic. Precise pressure application is the single most critical variable for establishing the uniform density required to prevent cracking and ensure high ionic conductivity in the final sintered pellet.

The Mechanics of Densification

Particle Rearrangement and Deformation

When pressure is applied, loose LLZO particles do not merely compress; they physically move. The hydraulic press forces particles to slide past one another to fill void spaces.

As pressure increases, the particles undergo plastic deformation, changing shape to interlock more tightly. This creates the initial structural integrity necessary for the material to hold its shape once removed from the mold.

Eliminating Density Gradients

A high-precision press utilizes sensitive pressure sensors and closed-loop control systems to ensure the load is applied evenly. This uniformity is vital for eliminating density gradients—areas where powder is packed tighter in some spots than others.

If the powder is not packed uniformly, the green body will have internal weak points. These inconsistencies inevitably lead to structural failure when the material is stressed during heating.

The Link Between Pressing and Sintering

Controlling Volume Shrinkage

The pressing stage sets the baseline for how much the material will shrink when fired. By maximizing the initial packing density, the hydraulic press reduces the total volume shrinkage that occurs during sintering.

Controlled shrinkage is essential for maintaining dimensional accuracy. It drastically reduces the risk of the pellet warping or deforming as it densifies at high temperatures.

Optimizing Inter-Particle Contact

For LLZO to become a dense ceramic, the particles must fuse together at the atomic level. The press ensures optimal inter-particle contact, closing the gaps between grains.

This tight contact facilitates the diffusion process during sintering. Without it, the final material will remain porous, leading to low density and poor electrochemical performance.

Understanding the Trade-offs

The Risk of Localized Stress

While high pressure is generally beneficial for density, it must be applied with extreme stability. Fluctuations in pressure or poor mold alignment can introduce localized stress concentrations.

These stresses often remain invisible in the green body but release catastrophically during sintering. This results in cracking or delamination, rendering the LLZO pellet unusable for electrical measurements or battery assembly.

Making the Right Choice for Your Goal

To achieve the best results with your LLZO preparation, tailor your pressing strategy to your specific end-goal:

- If your primary focus is Final Density: Prioritize higher pressure loads to maximize plastic deformation and inter-particle contact, aiming for a green density that supports reaching >90% theoretical density after sintering.

- If your primary focus is Structural Integrity: Focus on the stability of the pressure application (closed-loop control) to ensure zero density gradients, which is the primary cause of cracking during the heating ramp.

The hydraulic press is not just a shaping tool; it is the instrument that establishes the fundamental microstructure of your final electrolyte material.

Summary Table:

| Process Stage | Function of Hydraulic Press | Impact on Final LLZO Ceramic |

|---|---|---|

| Powder Compaction | Forces particle rearrangement and plastic deformation | Establishes initial mechanical strength and shape |

| Density Control | Eliminates density gradients via precise axial pressure | Prevents warping, cracking, and structural failure |

| Sintering Prep | Maximizes inter-particle contact points | Facilitates atomic diffusion for high ionic conductivity |

| Volume Management | Increases green body packing density | Reduces total shrinkage and improves dimensional accuracy |

Elevate Your LLZO Research with KINTEK Precision

Achieving the perfect green body is the foundation of high-performance solid-state electrolytes. KINTEK provides industry-leading laboratory hydraulic presses designed for the rigorous demands of LLZO preparation. Backed by expert R&D and manufacturing, we offer customizable solutions—including vacuum systems and high-temp furnaces—to ensure your materials achieve maximum density and zero defects.

Ready to optimize your ceramic synthesis? Contact KINTEK today for a consultation and discover the power of precision engineering.

Visual Guide

References

- Degradation mechanisms in low-voltage Wadsley–Roth TiNb<sub>2</sub>O<sub>7</sub> electrodes upon cycling with Li. DOI: 10.1039/d4ta06441k

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- Vacuum Hot Press Furnace Machine Heated Vacuum Press

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

People Also Ask

- What substances are prohibited from being introduced into the furnace chamber? Prevent Catastrophic Failure

- What is the function of the laboratory-scale condensation collection device? Optimize Multi-Stage Magnesium Separation

- What role does a high-precision lab stirring device play in KR experiments? Optimizing Desulfurization Simulation

- How does a laboratory drying oven ensure the structural stability of microcapsule granules? Expert Drying Guide

- Why are Zirconium Dioxide (ZrO2) crucibles used for slag-metal experiments? Ensure High-Temperature Chemical Purity

- Why is a rotary evaporator used to process separated fractions in hydrotreated coal tar analysis? Enhance Sample Purity

- What are the maximum working pressure specifications for water circulating vacuum pumps? Ensure Safe Operation and Avoid Failure

- What are the power specifications for a typical circulating water vacuum pump? Key Specs for Lab Efficiency