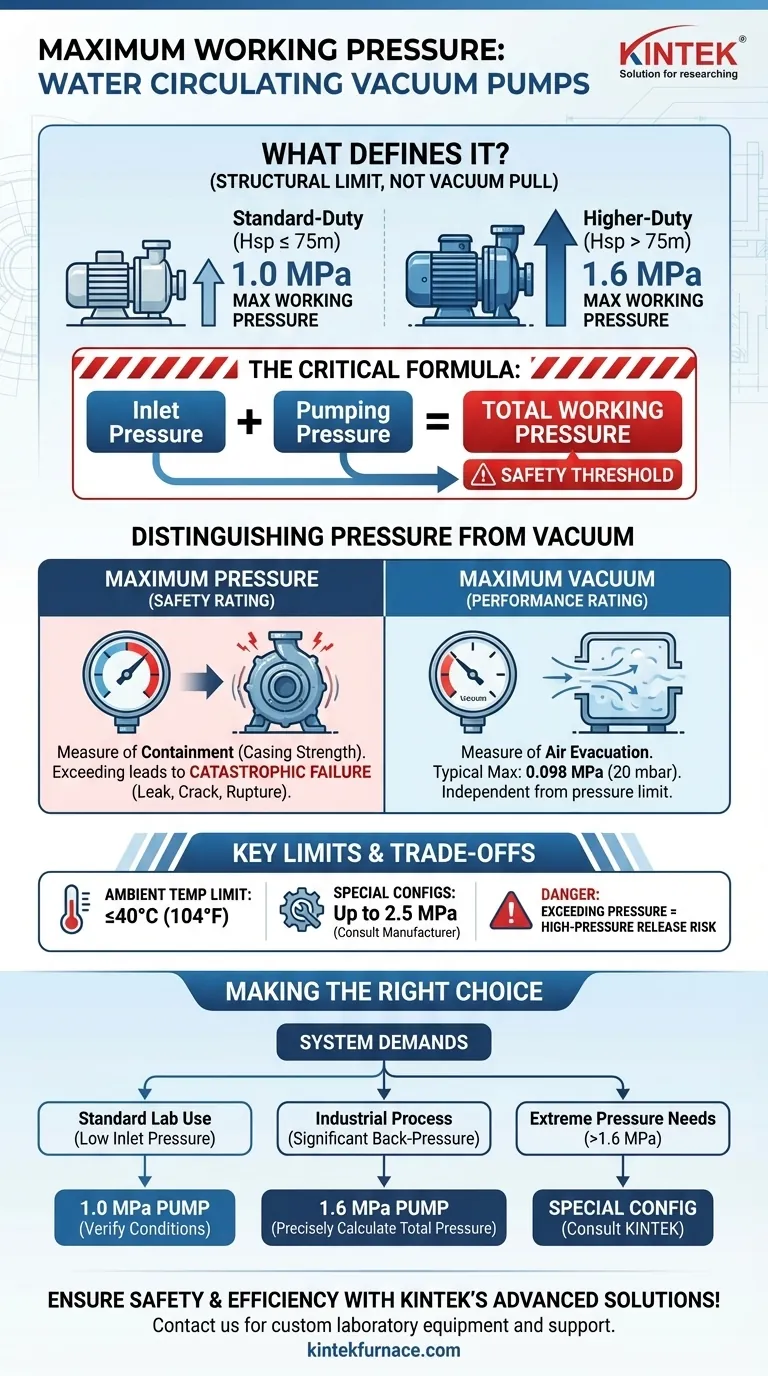

For a water circulating vacuum pump, the maximum working pressure is typically 1.0 MPa for models with a pump head (Hsp) of 75 meters or less, and 1.6 MPa for models with a head greater than 75 meters. It is critical to understand that this value is the sum of the system's inlet pressure and the pressure added by the pump itself. In some cases, special configurations can be specified to handle pressures up to 2.5 MPa.

Understanding "maximum working pressure" is not about the vacuum a pump can pull, but about the structural limit of its casing. Exceeding this combined pressure (inlet + pump) can lead to catastrophic failure, making it a critical safety specification.

What Defines "Maximum Working Pressure"?

The term "working pressure" can be misleading. It does not refer to the vacuum level the pump generates, but rather the total internal pressure the pump's body and seals can safely contain.

The Critical Formula: Inlet + Pumping Pressure

The manufacturer's rating is based on a simple but crucial formula: Total Working Pressure = Inlet Pressure + Pumping Pressure.

This means the pressure of the fluid entering the pump directly impacts its operational limits. If your system already has a high static or line pressure, the pump has less "room" to add its own pressure before exceeding the safety threshold.

The Role of 'Hsp' (Pump Head)

The specification Hsp refers to the pump's head, a measure of its power to move water to a certain height. This value directly correlates to the pump's construction.

- Pumps with Hsp ≤ 75m: These are standard-duty pumps with a maximum working pressure of 1.0 MPa.

- Pumps with Hsp > 75m: These are higher-duty pumps, built more robustly to achieve greater pumping force, and have a maximum working pressure of 1.6 MPa.

Special Configurations for Higher Pressures

For applications that demand even greater pressure tolerance, manufacturers can often supply pumps with special configurations. These reinforced models can achieve ratings of 1.6 MPa or even 2.5 MPa, but they must be explicitly requested.

Distinguishing Pressure from Vacuum

A common point of confusion is the difference between the pump's pressure limit and its vacuum capability. These are two independent performance metrics.

Maximum Pressure: A Measure of Containment

This is a safety rating. It tells you the maximum internal force the pump casing can withstand before it leaks, cracks, or ruptures. The 1.0 MPa or 1.6 MPa rating falls into this category.

Maximum Vacuum: A Measure of Performance

This is a performance rating. It specifies how much air the pump can evacuate from a sealed system. A typical water circulating vacuum pump can achieve a maximum vacuum of 0.098 MPa (or 20 mbar), meaning it can reduce the pressure inside a vessel to near-vacuum conditions.

Understanding the Trade-offs and Key Limits

Properly specifying and operating a pump requires understanding its limitations beyond a single number.

The Danger of Exceeding Working Pressure

Operating a pump beyond its maximum working pressure is extremely dangerous. The primary risk is a failure of the pump casing or seals, causing a high-pressure release of the working fluid.

The Impact of Inlet Pressure

A high inlet pressure is the most common reason for unintentionally exceeding the working pressure limit. As noted, if the inlet pressure is very low (e.g., below 0.03 MPa), system design is simpler and the risk is minimal. Always account for your system's starting pressure when selecting a pump.

Environmental and Temperature Limits

Beyond pressure, other factors affect reliability. These pumps are generally designed to operate in an ambient temperature of 40°C (104°F) or less. Higher temperatures can degrade performance and shorten the life of motor and seal components.

Making the Right Choice for Your Goal

Use the total calculated pressure of your system to guide your selection.

- If your primary focus is standard laboratory use with low inlet pressure: A standard pump rated for 1.0 MPa is likely sufficient, but always verify your system's conditions.

- If your primary focus is an industrial process with significant back-pressure: You must select a higher-rated pump (1.6 MPa) and precisely calculate the total working pressure to ensure a safe margin.

- If your application requires pressure containment above 1.6 MPa: You must consult directly with the manufacturer to source a special, high-pressure configuration.

Correctly matching the pump's pressure rating to your system's demands is the key to ensuring both safety and long-term reliability.

Summary Table:

| Specification | Details |

|---|---|

| Max Working Pressure (Hsp ≤ 75m) | 1.0 MPa |

| Max Working Pressure (Hsp > 75m) | 1.6 MPa |

| Special Configurations | Up to 2.5 MPa |

| Max Vacuum Capability | 0.098 MPa (20 mbar) |

| Ambient Temperature Limit | 40°C (104°F) |

Ensure your laboratory's safety and efficiency with KINTEK's advanced high-temperature furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with reliable equipment like Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability allows us to precisely meet your unique experimental requirements, ensuring optimal performance and durability. Don't risk system failure—contact us today to discuss how we can support your specific needs and enhance your operations!

Visual Guide

Related Products

- Ultra Vacuum Electrode Feedthrough Connector Flange Power Lead for High Precision Applications

- 304 316 Stainless Steel High Vacuum Ball Stop Valve for Vacuum Systems

- Laboratory Vacuum Tilt Rotary Tube Furnace Rotating Tube Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

People Also Ask

- What is the maximum temperature limit for a standard water circulating vacuum pump and what can it reach with special configuration? Discover High-Temp Solutions

- What is the purpose of a laboratory vacuum chamber in sacrificial material ink prep? Ensure Structural Integrity.

- How does the use of Matched Thermal Baffles (MTB) benefit directional solidification? Achieve Superior Crystal Integrity

- What is the importance of using a cooling jacketed sampling probe? Ensure Accurate Drop Tube Furnace Data

- What are the roles of rotameters and digital flow controllers in pneumatic systems? Enhance Precision and Testing

- How does a Mass Flow Controller (MFC) influence CrAlSiN coatings? Precision Ar/N2 Control for Hardness

- What is the function of a high-precision thermogravimetric analyzer? Expert Insights into Moxa Floss Thermal Analysis

- What key functions do graphite molds serve during the hot press sintering? Enhance Ti/Al2O3 Composite Quality