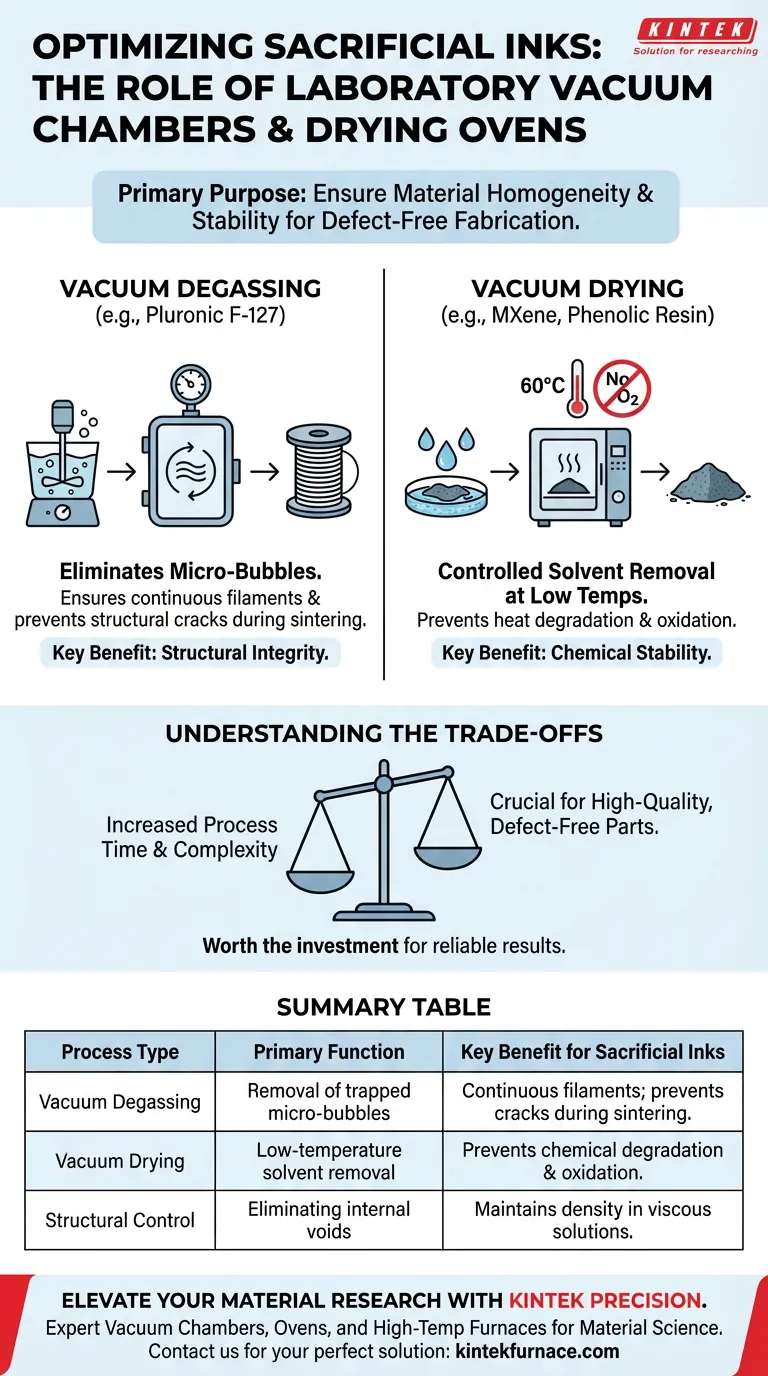

The primary purpose of a laboratory vacuum chamber or vacuum drying oven in this context is ensuring material homogeneity and stability. Specifically, for sacrificial inks like Pluronic F-127, the vacuum chamber is used to degas the solution, removing trapped micro-bubbles introduced during mixing. This ensures the extruded filaments remain continuous and dense, preventing structural failure in the final component.

By creating a void-free and chemically stable material, vacuum processing acts as a critical quality assurance step. It prevents physical defects like cracking during sintering and protects sensitive chemical components from oxidation during drying.

Ensuring Structural Integrity via Degassing

The Problem of Micro-Bubbles

When preparing viscous sacrificial inks, such as those based on Pluronic F-127, the stirring process inevitably traps air within the mixture.

If left untreated, these micro-bubbles compromise the density of the concentrated polymer solution.

Enhancing Filament Continuity

A vacuum chamber removes these trapped gases before the material is loaded into a 3D printer.

This degassing step is vital to ensure that the extruded filaments are continuous.

Without this process, air pockets would cause interruptions in the material flow, resulting in gaps within the printed structure.

Preventing Post-Processing Defects

The benefits of vacuum degassing extend beyond the printing phase into post-processing.

By ensuring a dense, bubble-free ink, you prevent the formation of defects in functional channels.

Furthermore, eliminating these voids is crucial for avoiding structural cracking that can occur during the high-stress sintering process.

Preserving Chemical Stability via Vacuum Drying

Controlled Solvent Removal

In the preparation of complex precursors, such as N-TiO2@NC, a vacuum drying oven is utilized to remove residual solvents.

This allows for effective drying at significantly lower temperatures, such as 60 degrees Celsius.

Lowering the thermal requirement protects the material from heat-induced degradation before it is ready for final processing.

Prevention of Oxidation

Operating in a vacuum environment excludes oxygen and moisture from the drying process.

This is essential for protecting reactive components, such as MXene nanosheets, from oxidation.

It also helps maintain the structural integrity of coatings, such as phenolic resin, ensuring the material is chemically prepared for subsequent high-temperature thermal treatments.

Understanding the Trade-offs

Process Time vs. Material Quality

Utilizing vacuum chambers adds a distinct step to the workflow, increasing the total preparation time for the ink.

However, skipping this step creates a high risk of part rejection due to internal voids that are often invisible until the sintering phase.

Equipment Complexity

Vacuum drying requires precise control over pressure and temperature to prevent rapid boiling of solvents, which could damage the material structure.

While this requires specialized equipment and monitoring, it is the only reliable method to dry oxidation-prone materials without altering their chemical composition.

Making the Right Choice for Your Goal

To apply this to your specific project, determine whether your primary challenge is physical consistency or chemical preservation.

- If your primary focus is printability and physical structure: Prioritize using a vacuum chamber for degassing to remove micro-bubbles and ensure continuous, crack-free filaments.

- If your primary focus is preventing oxidation in sensitive precursors: Prioritize using a vacuum drying oven to remove solvents at low temperatures while excluding oxygen.

Mastering the vacuum environment is the difference between a theoretical ink formulation and a functional, defect-free application.

Summary Table:

| Process Type | Primary Function | Key Benefit for Sacrificial Inks |

|---|---|---|

| Vacuum Degassing | Removal of trapped micro-bubbles | Ensures continuous filaments and prevents cracks during sintering. |

| Vacuum Drying | Low-temperature solvent removal | Prevents chemical degradation and oxidation of sensitive components (e.g., MXenes). |

| Structural Control | Eliminating internal voids | Maintains density in viscous solutions like Pluronic F-127. |

Elevate Your Material Research with KINTEK Precision

Don't let micro-bubbles or oxidation compromise your breakthrough. Backed by expert R&D and manufacturing, KINTEK offers high-performance Vacuum Chambers, Vacuum Drying Ovens, and customizable lab high-temp furnaces designed to meet the rigorous demands of material science.

Whether you are preparing Pluronic F-127 inks or sensitive MXene nanosheets, our systems provide the precise control needed for defect-free results. Contact us today to find the perfect solution for your lab and see how our customizable equipment can optimize your workflow.

Visual Guide

References

- Highly Stable Low‐Temperature Phosphate Glass as a Platform for Multimaterial 3D Printing of Integrated Functional Microfluidic Devices. DOI: 10.1002/adem.202501603

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- Vacuum Heat Treat Sintering and Brazing Furnace

- Vacuum Induction Melting Furnace

People Also Ask

- Why use a PLC and touch screen for magnesium vacuum distillation? For Superior Control and Safety

- What is the specific function of a laboratory high-temperature furnace? Master Lost-PLA Burnout Success

- What are the key properties of quartz tubes that make them versatile across industries? Discover Their Thermal, Chemical, and Optical Benefits

- Can alumina ceramic furnace tubes be customized for specific applications? Enhance Your High-Temperature Processes

- What is the role of a laboratory oven in the pre-treatment of Date Palm Stones? Enhance Torrefaction & Grinding Efficiency

- Why are high-purity zirconia grinding balls preferred over steel? Achieve Ultra-Pure Ceramic Grinding Results

- How are laboratory vacuum pumps utilized in 1T-TaS2 crystal preparation? Ensure Peak Sample Purity

- What accessories are used with silicon carbide heating elements and their functions? Ensure Reliable Performance and Longevity