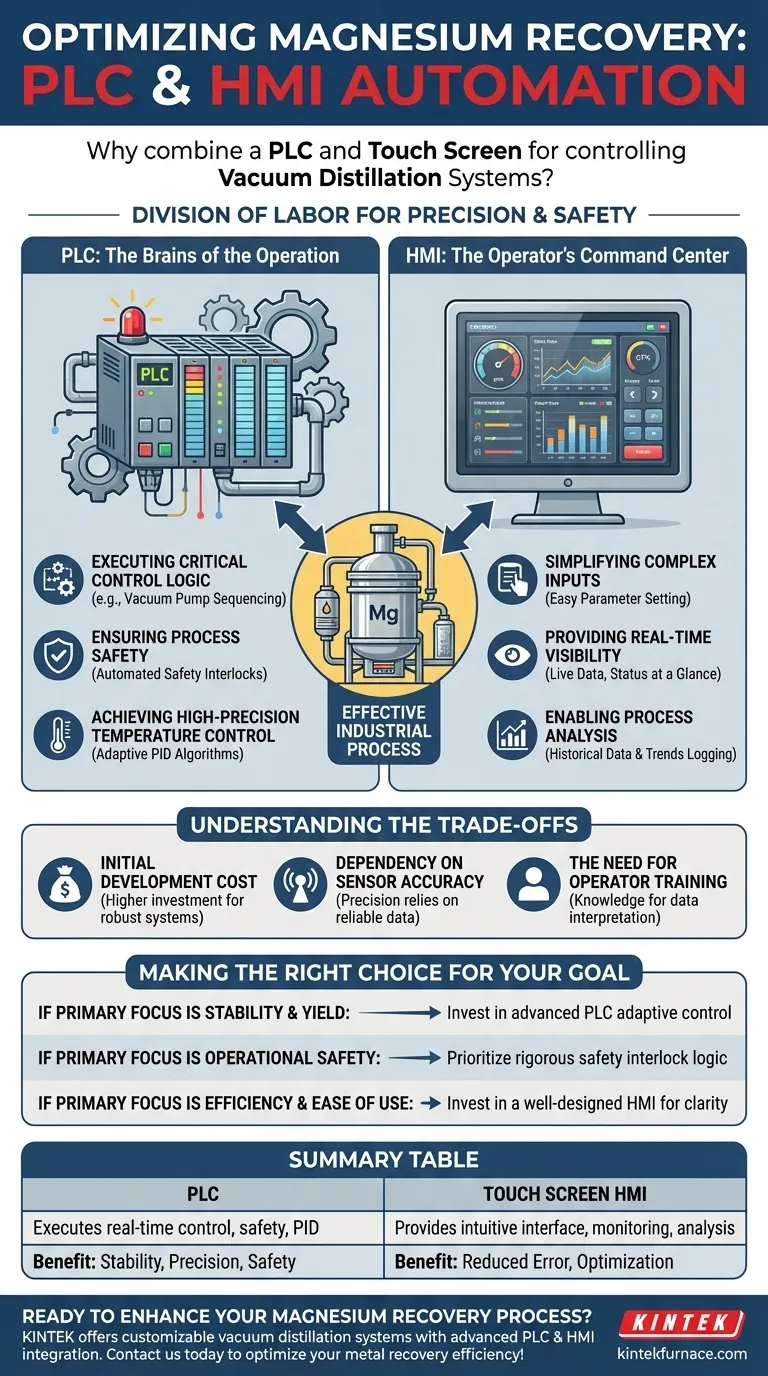

At its core, an automation solution combining a PLC and a touch screen is used for magnesium vacuum distillation because it separates the two most critical functions: the robust, real-time process control handled by the PLC, and the intuitive operator interface provided by the touch screen. This division of labor allows the system to achieve the high levels of precision, safety, and repeatability required for an effective industrial process.

The fundamental challenge in magnesium distillation is managing a complex process with extremely tight tolerances for temperature and vacuum. The PLC/HMI combination solves this by delegating the demanding, high-speed control logic to the PLC, while giving the human operator a clear, simplified window for supervision and management through the HMI.

The PLC: The Brains of the Operation

The Programmable Logic Controller (PLC) is the industrial computer that executes the core logic of the distillation system. It operates independently and is designed for extreme reliability in harsh environments.

Executing Critical Control Logic

The PLC runs the step-by-step program that controls the entire process. This includes complex tasks like vacuum pump sequencing, ensuring different pumps activate in the correct order to achieve the required vacuum level without damaging the equipment.

Ensuring Process Safety

Safety is paramount. The PLC constantly monitors the system for unsafe conditions and executes pre-programmed safety interlocks. For example, it can automatically shut down a heating element if a critical temperature is exceeded or a vacuum leak is detected.

Achieving High-Precision Temperature Control

Recovering magnesium requires exceptionally stable temperatures. The PLC can run advanced algorithms like adaptive PID (Proportional-Integral-Derivative) control, which continuously adjusts heating output to maintain temperature with a high degree of accuracy, far beyond what is possible with manual control.

The HMI: The Operator's Command Center

The touch screen, or Human-Machine Interface (HMI), acts as the dashboard for the entire system. It translates the PLC's complex data into a visual, interactive format for the operator.

Simplifying Complex Inputs

Instead of manipulating physical dials or switches, operators can use the touch screen to easily set key process parameters, such as temperature setpoints, ramp rates, and vacuum targets. This reduces the chance of human error.

Providing Real-Time Visibility

The HMI displays critical data in real-time through graphs, gauges, and numerical readouts. Operators can instantly see the current furnace temperature, vacuum levels, and the status of all equipment at a single glance.

Enabling Process Analysis

A key function of the HMI is to log and display historical data and trends. This allows engineers and operators to review past cycles, troubleshoot issues, and optimize the process for better yield and efficiency.

Understanding the Trade-offs

While this combination is the industry standard for good reason, it's important to understand the associated considerations.

Initial Development Cost

Designing and programming a robust PLC/HMI system requires specialized expertise. The initial investment in hardware and software development is higher than for simpler, less capable control systems.

Dependency on Sensor Accuracy

The entire control system is only as good as the data it receives. The precision of the PLC is entirely dependent on the accuracy and reliability of the thermocouples, vacuum gauges, and other sensors connected to it.

The Need for Operator Training

While an HMI simplifies operation, it does not eliminate the need for knowledgeable operators. Personnel must still understand the underlying distillation process to interpret the data correctly and respond effectively to alarms or unexpected events.

Making the Right Choice for Your Goal

When implementing such a system, your specific priorities will shape the design.

- If your primary focus is process stability and yield: The PLC's ability to execute advanced adaptive control algorithms for temperature is the most critical feature to invest in.

- If your primary focus is operational safety: Prioritize the comprehensive design and rigorous testing of the PLC's safety interlock logic to cover all potential failure scenarios.

- If your primary focus is efficiency and ease of use: Invest heavily in a well-designed HMI that presents complex data clearly, minimizing the cognitive load on the operator.

Ultimately, this integrated automation approach transforms a demanding industrial process into a highly controlled, predictable, and efficient operation.

Summary Table:

| Component | Key Function | Benefit in Magnesium Distillation |

|---|---|---|

| PLC | Executes real-time control logic, safety interlocks, and adaptive PID temperature control. | Ensures process stability, high precision, and equipment safety. |

| Touch Screen HMI | Provides intuitive interface for parameter setting, real-time monitoring, and historical data analysis. | Reduces operator error and enables easy troubleshooting and optimization. |

Ready to enhance your magnesium recovery process with a reliable, automated control system?

Backed by expert R&D and manufacturing, KINTEK offers customizable vacuum distillation systems with advanced PLC and HMI integration. Our solutions ensure precise temperature control, robust safety interlocks, and user-friendly operation tailored to your unique needs.

Contact us today to discuss how we can optimize your metal recovery efficiency!

Visual Guide

Related Products

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- Vacuum Hot Press Furnace Machine Heated Vacuum Press

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

People Also Ask

- How do atmosphere furnaces contribute to ceramic manufacturing? Enhance Purity and Performance

- What are the primary inert gases used in vacuum furnaces? Optimize Your Heat Treatment Process

- How do argon and nitrogen protect samples in vacuum furnaces? Optimize Your Thermal Process with the Right Gas

- What are some specific applications of atmosphere furnaces in the ceramics industry? Enhance Purity and Performance

- What is inert gas technology used for in high-temperature atmosphere vacuum furnaces? Protect Materials and Speed Up Cooling