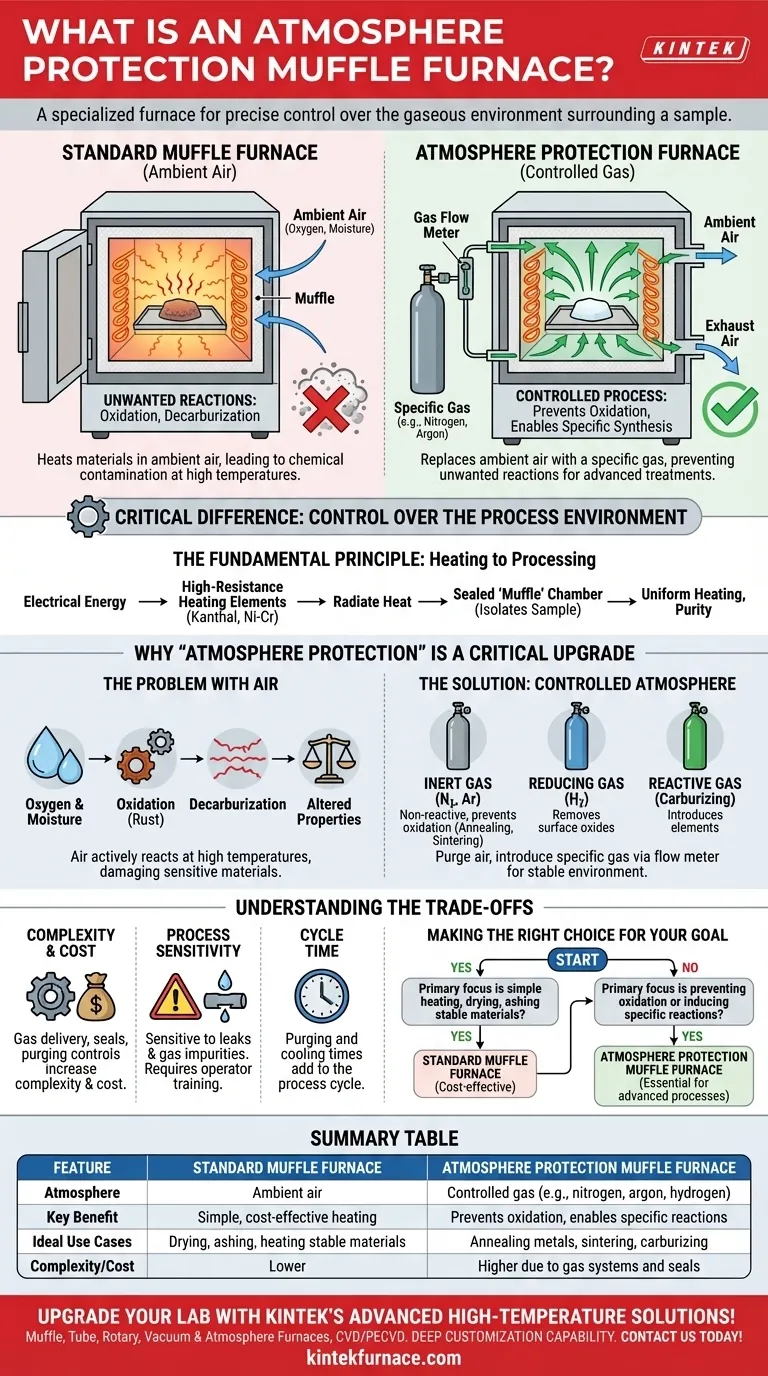

At its core, an atmosphere protection muffle furnace is a specialized type of high-temperature furnace that allows for precise control over the gaseous environment surrounding a sample. While a standard muffle furnace heats materials in ambient air, an atmosphere protection model replaces that air with a specific gas. This control prevents unwanted chemical reactions, such as oxidation, that would otherwise occur at elevated temperatures.

The critical difference is control over the process environment. A standard muffle furnace simply heats a sample in air; an atmosphere protection furnace heats it within a carefully managed gas atmosphere, enabling heat treatments and material synthesis that are impossible in the open air.

The Fundamental Principle: From Heating to Processing

To understand the value of atmosphere protection, we must first understand the basic function of any muffle furnace. It is a tool designed for clean, uniform, and precise heating.

How a Standard Muffle Furnace Works

A muffle furnace operates by converting electrical energy into heat. Electricity passes through high-resistance heating elements, often made of materials like Kanthal or nickel-chromium.

These elements radiate heat into a sealed, insulated chamber known as the "muffle." The sample placed inside this chamber is heated uniformly without any direct contact with flames or combustion byproducts, ensuring purity.

The Role of the Muffle

The term "muffle" refers to the chamber that isolates the sample from the heating elements. This separation is crucial for preventing chemical contamination and ensuring that the temperature across the sample is consistent.

Why "Atmosphere Protection" is a Critical Upgrade

The primary limitation of a standard muffle furnace is the atmosphere itself: ambient air. For many advanced processes, air is not a neutral bystander but an active chemical agent.

The Problem with Air

At high temperatures, the oxygen and moisture present in normal air can aggressively react with many materials. This can cause oxidation (like rust on steel), decarburization, or other unwanted chemical changes that alter the material's properties.

For processes like sintering metal powders or annealing sensitive alloys, exposure to oxygen can ruin the final product.

Introducing a Controlled Atmosphere

An atmosphere protection furnace solves this problem by allowing you to purge the chamber of ambient air and replace it with a specific gas. A gas flow meter is used to regulate the introduction of this new atmosphere, ensuring it remains stable throughout the process.

Common atmospheres include:

- Inert Gas (Nitrogen, Argon): Used to create a non-reactive environment to prevent oxidation during annealing or sintering.

- Reducing Gas (Hydrogen, Forming Gas): Used to actively remove surface oxides from a material.

- Reactive Gas (Carburizing Atmospheres): Used to intentionally introduce elements into the material's surface.

Understanding the Trade-offs

While powerful, atmosphere protection furnaces are not universally necessary. Their specialized nature comes with specific considerations.

Increased Complexity and Cost

The addition of gas delivery systems, airtight seals, and purging controls makes these furnaces significantly more complex and expensive than their standard counterparts. The need for a gas supply also adds to the operational cost.

Process Sensitivity

Achieving and maintaining a perfectly pure atmosphere is challenging. The process is sensitive to leaks in the chamber seals or impurities in the gas supply, which can compromise the results. Proper operator training is essential.

Cycle Time

Purging the chamber of air before heating and ensuring the sample is cool before exposing it to air again can add significant time to the overall process cycle.

Making the Right Choice for Your Goal

Selecting the correct furnace depends entirely on the chemical requirements of your high-temperature process.

- If your primary focus is simple heating, drying, or ashing materials that are stable in air: A standard muffle furnace is the most direct and cost-effective solution.

- If your primary focus is preventing oxidation during heat treatment (e.g., annealing metals, sintering ceramics): An atmosphere protection furnace with an inert gas like nitrogen or argon is essential.

- If your primary focus is to induce a specific surface chemical reaction (e.g., carburizing steel): You must use an atmosphere furnace designed to safely handle the required reactive gases.

Ultimately, your choice depends on a single question: does the air in the room interfere with your desired outcome?

Summary Table:

| Feature | Standard Muffle Furnace | Atmosphere Protection Muffle Furnace |

|---|---|---|

| Atmosphere | Ambient air | Controlled gas (e.g., nitrogen, argon, hydrogen) |

| Key Benefit | Simple, cost-effective heating | Prevents oxidation, enables specific chemical reactions |

| Ideal Use Cases | Drying, ashing, heating stable materials | Annealing metals, sintering, carburizing |

| Complexity/Cost | Lower | Higher due to gas systems and seals |

Upgrade your lab with KINTEK's advanced high-temperature furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with tailored options like Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures precise solutions for your unique experimental needs, enhancing efficiency and results. Contact us today to discuss how we can support your specific applications!

Visual Guide

Related Products

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1400℃ Muffle Oven Furnace for Laboratory

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

- Laboratory Muffle Oven Furnace with Bottom Lifting

People Also Ask

- What is inert gas technology used for in high-temperature atmosphere vacuum furnaces? Protect Materials and Speed Up Cooling

- How does the pressure range change under vacuum conditions in an atmosphere box furnace? Explore Key Shifts for Material Processing

- Can box type high-temperature resistance furnaces control the atmosphere? Unlock Precision in Material Processing

- What are some specific applications of atmosphere furnaces in the ceramics industry? Enhance Purity and Performance

- What are the primary inert gases used in vacuum furnaces? Optimize Your Heat Treatment Process