In short, inert gas technology serves two primary functions in high-temperature atmosphere and vacuum furnaces. First, it creates a chemically non-reactive environment to protect materials from oxidation and other unwanted reactions. Second, it is used as a medium for controlled, rapid cooling, which can significantly shorten process cycle times and influence the final properties of the material.

At high temperatures, materials become highly vulnerable to chemical changes and thermal stress. Inert gas technology is fundamentally a tool for control—providing precise chemical protection and thermal management to ensure the integrity and desired properties of the final product.

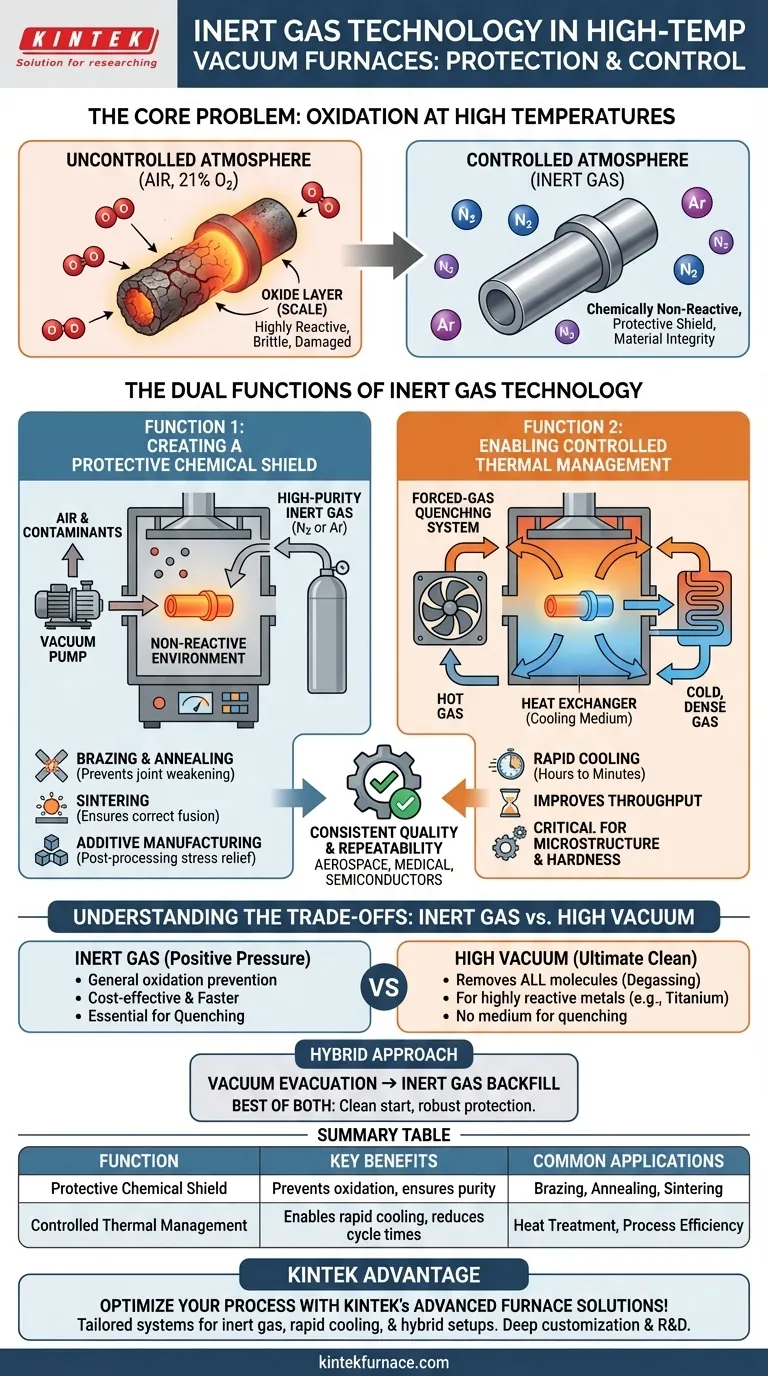

The Core Problem: Why a Controlled Atmosphere is Non-Negotiable

At the elevated temperatures found in these furnaces, materials are in a highly reactive state. Introducing a controlled atmosphere isn't an optional feature; it's a fundamental requirement for achieving a successful outcome.

Preventing Oxidation and Unwanted Reactions

The air we breathe is about 21% oxygen, which is extremely reactive at high temperatures. Exposing a hot workpiece to oxygen can cause immediate and irreversible damage, such as forming a brittle oxide layer (scale) on metals.

Inert gases, most commonly nitrogen and argon, are used because they are non-reactive. They physically displace the oxygen and other atmospheric contaminants, creating a protective shield around the workpiece.

Ensuring Process Repeatability and Quality

An uncontrolled atmosphere is an unpredictable variable. An inert gas atmosphere, however, is a known constant.

This consistency is critical for high-precision industries like aerospace, medical implants, and semiconductors, where even minute variations in material properties can lead to component failure. Using an inert atmosphere ensures that every part processed under the same recipe comes out with identical characteristics.

The Dual Functions of Inert Gas Technology

Inert gas is not just a passive shield; it is an active tool used to manipulate the furnace environment for two distinct purposes.

Function 1: Creating a Protective Chemical Shield

The primary role of inert gas is to create a non-reactive environment. The furnace chamber is first evacuated to remove the air and then backfilled with a high-purity inert gas.

This is essential for processes where material purity and surface finish are paramount, including:

- Brazing and Annealing: Prevents oxidation that would weaken joints or alter material hardness.

- Sintering: Ensures that powdered metals or ceramics fuse correctly without forming unwanted chemical compounds.

- Additive Manufacturing: Used in post-processing 3D-printed metal parts to relieve stress without compromising the material's integrity.

Function 2: Enabling Controlled Thermal Management

The second key function is forced-gas quenching or rapid cooling. After the heating cycle is complete, the workpieces must be cooled in a controlled manner.

A powerful fan circulates the inert gas through a heat exchanger to cool it, then forces it back into the hot zone at high velocity. The cold, dense gas rapidly absorbs heat from the workpiece and furnace insulation, drastically reducing the cooling time from many hours to minutes. This not only improves throughput but is also critical for achieving specific microstructures and hardness in heat-treatable alloys.

Understanding the Trade-offs: Inert Gas vs. High Vacuum

Many furnaces can operate with either an inert gas atmosphere or a high vacuum. The choice depends entirely on the material and the process goal.

When to Choose Inert Gas

Inert gas is ideal for general-purpose oxidation prevention. It is often more cost-effective and faster to achieve a positive pressure of inert gas than to pull and maintain a very deep vacuum. It is also the only option when forced-gas quenching is required, as there is no medium to circulate in a vacuum.

When to Choose High Vacuum

A high vacuum is the ultimate clean environment. It is used when the goal is not just to prevent reactions with oxygen, but to remove all atmospheric molecules, including the inert gas itself. This is critical for degassing materials or processing extremely reactive metals like titanium and refractory metals, which can react even with nitrogen at high temperatures.

The Hybrid Approach: The Best of Both Worlds

The most common industrial practice involves using both. A furnace will first be pumped down to a medium or high vacuum to remove all air and moisture. It is then backfilled with high-purity inert gas to the desired pressure for the heating cycle. This ensures an extremely clean starting environment.

Making the Right Choice for Your Process

Your process requirements will dictate the ideal atmospheric control strategy.

- If your primary focus is preventing surface oxidation on common materials (e.g., steel): A nitrogen atmosphere is typically the most economical and effective solution.

- If your primary focus is processing highly reactive materials (e.g., titanium) or ensuring absolute purity: A high-vacuum process, potentially backfilled with high-purity argon, is necessary.

- If your primary focus is reducing cycle times through rapid cooling: A furnace equipped with an inert gas quenching system is essential.

- If your primary focus is general heat treatment like brazing or sintering: The hybrid approach of evacuating and then backfilling with nitrogen or argon provides robust protection.

By understanding these principles, you can select the precise atmospheric controls needed to guarantee your material's integrity and your process's efficiency.

Summary Table:

| Function | Key Benefits | Common Applications |

|---|---|---|

| Protective Chemical Shield | Prevents oxidation and unwanted reactions, ensures material purity | Brazing, annealing, sintering, additive manufacturing |

| Controlled Thermal Management | Enables rapid cooling (forced-gas quenching), reduces cycle times, influences material properties | Heat treatment of alloys, process efficiency improvement |

Optimize your high-temperature processes with KINTEK's advanced furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with tailored high-temperature furnace systems, including Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures precise alignment with your unique experimental needs, whether for inert gas applications, rapid cooling, or hybrid vacuum setups. Contact us today to enhance material integrity and boost efficiency in your operations!

Visual Guide

Related Products

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- Laboratory Muffle Oven Furnace with Bottom Lifting

- Controlled Inert Nitrogen Hydrogen Atmosphere Furnace

People Also Ask

- What are some specific applications of atmosphere furnaces in the ceramics industry? Enhance Purity and Performance

- What is an atmosphere protection muffle furnace? Unlock Precise Heat Treatment in Controlled Environments

- What are the primary inert gases used in vacuum furnaces? Optimize Your Heat Treatment Process

- How does the pressure range change under vacuum conditions in an atmosphere box furnace? Explore Key Shifts for Material Processing

- What are the development prospects of atmosphere box furnaces in the aerospace industry? Unlock Advanced Material Processing for Aerospace Innovation