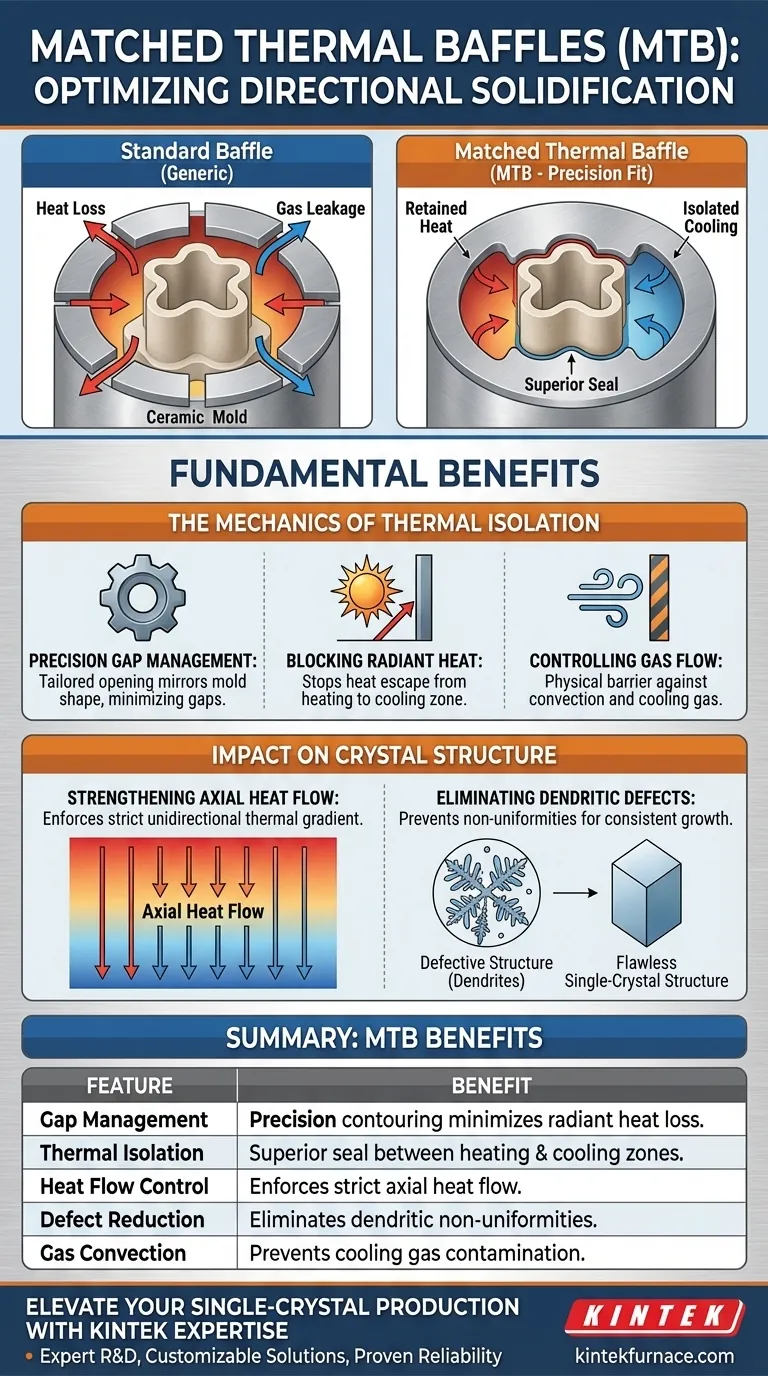

Matched Thermal Baffles (MTB) fundamentally enhance directional solidification by tailoring the baffle opening to contour precisely to the complex shape of the ceramic mold. This high-precision fit creates a superior seal between the furnace's heating and cooling zones, drastically reducing heat loss through the gaps. The result is a more stable thermal environment that enforces strict axial heat flow, which is critical for preventing structural defects in single-crystal components.

By minimizing the physical gap between the baffle and the mold, MTBs maximize thermal isolation. This intensification of the axial temperature gradient is the primary mechanism for eliminating atypical dendritic non-uniformities and ensuring consistent crystal growth.

The Mechanics of Thermal Isolation

Precision Gap Management

Standard baffles often leave gaps when accommodating complex mold geometries. Matched Thermal Baffles solve this by adjusting their opening profiles to closely mirror the external shape of the ceramic mold.

This tight tolerance minimizes the open area between the heating and cooling chambers.

Blocking Radiant Heat Transfer

The primary function of this tighter seal is to prevent radiant heat loss.

By closing the physical gaps, the baffle stops heat from escaping the heating chamber into the cooling zone, maintaining the high temperatures required for the melt while protecting the solidified structure below.

Controlling Gas Flow

Beyond radiant heat, the precise fit acts as a physical barrier against convection.

It prevents cooling gas from flowing upward into the heating zone. This isolation ensures that the cooling medium acts only on the solidified portion of the casting, preventing thermal contamination of the liquid melt.

Impact on Crystal Structure

Strengthening Axial Heat Flow

The goal of directional solidification is to force heat to move in one specific direction: longitudinally along the blade.

MTBs enhance the directionality of this axial heat flow. By isolating the temperature fields, the process ensures that the cooling front moves vertically without lateral thermal interference.

Eliminating Dendritic Defects

When heat flow becomes non-uniform, the internal structure of the metal can develop irregularities.

The improved isolation provided by MTBs helps eliminate atypical dendritic non-uniformities. This results in a homogeneous cross-section, which is essential for the mechanical integrity of single-crystal blades.

Understanding the Operational Requirements

The Necessity of Precision

The effectiveness of an MTB relies entirely on the accuracy of the profile match.

Because the baffle must fit "complex external shapes," the engineering tolerance is critical. A mismatch can either lead to heat leakage (reducing effectiveness) or mechanical interference with the mold.

Specificity vs. Flexibility

Using MTBs implies a move away from generic tooling.

Since the baffle is matched to the specific contour of a mold, it is inherently less flexible than a standard circular opening. This requires a dedicated approach to baffle design for each unique component geometry.

Making the Right Choice for Your Process

## Optimizing for Single-Crystal Integrity

- If your primary focus is defect reduction: Implement MTBs to eliminate atypical dendritic non-uniformities by enforcing a stricter axial temperature gradient.

- If your primary focus is thermal efficiency: Use the precise profiling of MTBs to minimize radiant heat loss and prevent cooling gas recirculation into the hot zone.

True directional solidification requires not just heat, but the precise control of where that heat goes; MTBs provide the geometry required to enforce that control.

Summary Table:

| Feature | Benefit of Matched Thermal Baffles (MTB) |

|---|---|

| Gap Management | Precision contouring to mold shape minimizes radiant heat loss. |

| Thermal Isolation | Creates a superior seal between heating and cooling furnace zones. |

| Heat Flow Control | Enforces strict axial heat flow for uniform crystal growth. |

| Defect Reduction | Eliminates atypical dendritic non-uniformities in single-crystal parts. |

| Gas Convection | Prevents cooling gas from contaminating the heating chamber. |

Elevate Your Single-Crystal Production with KINTEK Expertise

Precision in directional solidification requires absolute control over thermal gradients. At KINTEK, we provide the advanced laboratory and industrial high-temperature solutions necessary to achieve flawless material structures.

Why partner with KINTEK?

- Expert R&D and Manufacturing: Our systems are engineered for the most demanding thermal processes.

- Customizable Solutions: From Muffle and Tube furnaces to advanced Vacuum and CVD systems, we tailor our technology to your specific mold geometries and process requirements.

- Proven Reliability: Ensure consistent axial heat flow and eliminate structural defects with our high-precision equipment.

Ready to optimize your thermal isolation and enhance casting integrity? Contact our technical experts today to discuss your custom furnace needs!

Visual Guide

References

- Effect of Temperature Profile Curvature on the Formation of Atypical Inhomogeneity of Dendritic Microstructure Across the Width of a Single Crystal Blade. DOI: 10.1007/s11661-025-07909-y

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

- Vacuum Heat Treat Sintering and Brazing Furnace

- Vacuum Hot Press Furnace Machine for Lamination and Heating

People Also Ask

- What role does a quartz substrate holder play in MoS2 growth? Optimize Thin Film Deposition with Precision Hardware

- Why are laboratory hydraulic presses critical for FMDS pelletization? Boost Strength Without Heat

- What is the purpose of cleaning MgO substrates for ScN growth? Optimize Your Epitaxial Film Quality

- What is the function of a condensation crystallizer in a magnesium vapor recovery system? Master Purification & Yield

- How does a precise substrate heating system influence fluoride thin film quality? Mastering Structural Integrity

- What are the technical advantages of using a high-purity alumina crucible for the synthesis of MnBi2Te4?

- What creates the pumping action in a circulating water vacuum pump? Discover the Liquid Ring Mechanism

- How do a three-stub tuner and a sliding short contribute to microwave carbothermic reduction? Maximize Energy Efficiency