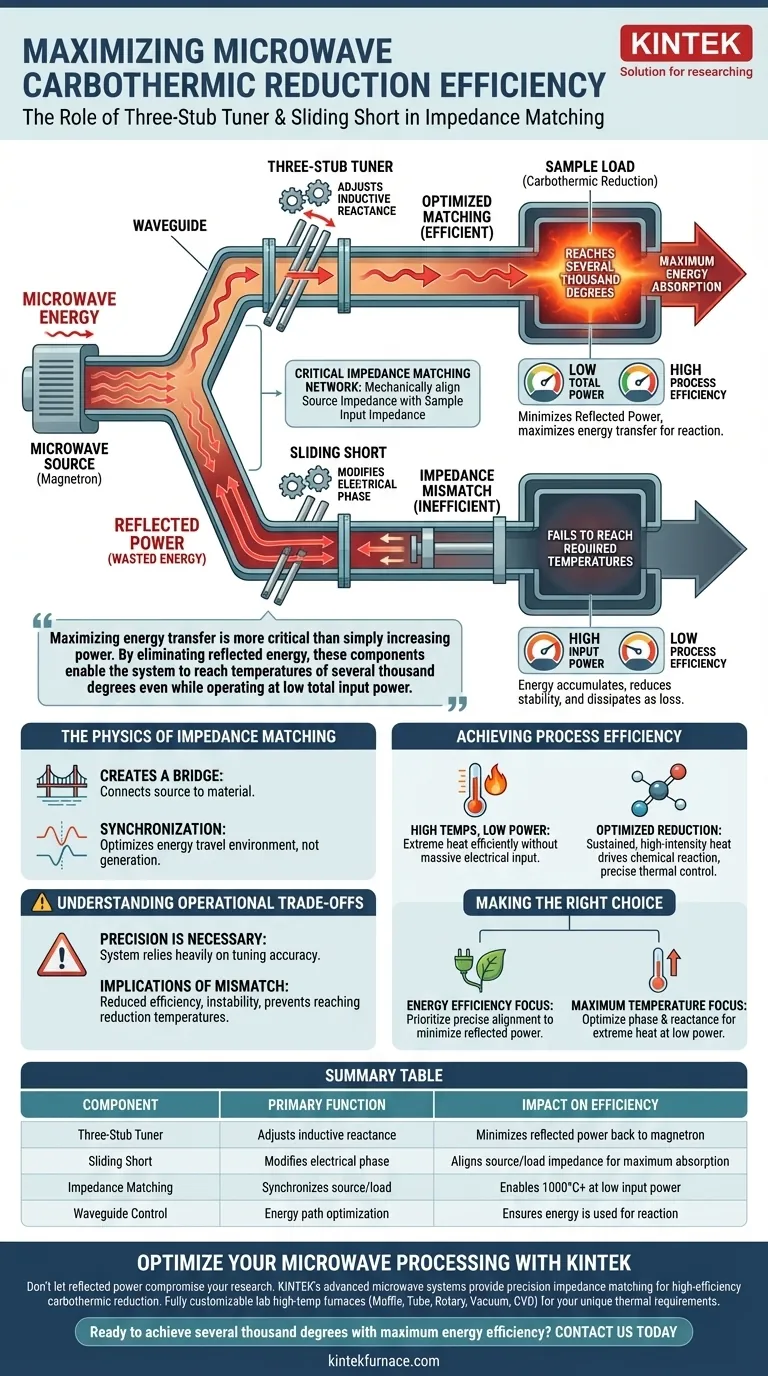

A three-stub tuner and a sliding short serve as the critical impedance matching network within a microwave system. Together, they mechanically adjust the inductive reactance and electrical phase inside the waveguide to align the source impedance of the magnetron with the input impedance of your sample. This synchronization minimizes reflected power, ensuring that the microwave energy is efficiently absorbed by the load rather than bouncing back to the source.

Maximizing energy transfer is more critical than simply increasing power. By eliminating reflected energy, these components enable the system to reach temperatures of several thousand degrees even while operating at low total input power.

The Physics of Impedance Matching

The Function of the Network

The three-stub tuner and sliding short do not generate energy; they optimize the environment through which the energy travels.

They function by modifying the inductive reactance and electrical phase within the waveguide structures.

This modification creates a bridge between the microwave source (the magnetron) and the material being processed (the sample load).

Minimizing Reflected Power

In any microwave system, a mismatch between the source and the load results in energy reflection.

Reflected energy is wasted energy; it travels back toward the magnetron instead of heating the sample.

By tuning these components to match the impedances perfectly, you drastically reduce this reflected power.

Achieving Process Efficiency

High Temperatures at Low Power

The primary contribution of this setup to carbothermic reduction is the ability to achieve extreme heat efficiently.

Because the energy transfer is optimized, the sample can reach several thousand degrees.

Crucially, this is achieved without requiring a massive electrical input, making the process energy-efficient.

Optimizing the Reduction Environment

Carbothermic reduction requires sustained, high-intensity heat to drive the chemical reaction.

The matching network ensures that the energy provided is utilized for this reaction rather than being dissipated as losses.

This allows for precise control over the thermal environment needed for successful reduction.

Understanding the Operational Trade-offs

The Necessity of Precision

While effective, this system relies heavily on the accuracy of the tuning.

If the inductive reactance or phase is not adjusted correctly, the system efficiency drops immediately.

Implications of Impedance Mismatch

Failing to match the impedance does not just result in lower temperatures.

High levels of reflected power can cause energy to accumulate in the waveguide or return to the magnetron.

This reduces the overall stability of the heating process and prevents the system from reaching the required reduction temperatures.

Making the Right Choice for Your Goal

To maximize the efficiency of your microwave carbothermic reduction process, focus on the tuning of your waveguide components.

- If your primary focus is energy efficiency: Prioritize the precise alignment of the tuner and sliding short to minimize reflected power, ensuring every watt of input is absorbed by the sample.

- If your primary focus is reaching maximum temperature: Use the matching network to optimize phase and reactance, allowing the load to reach thousands of degrees without increasing the generator's power output.

The success of your process depends not just on the power you generate, but on how effectively you tune the system to absorb it.

Summary Table:

| Component | Primary Function | Impact on Efficiency |

|---|---|---|

| Three-Stub Tuner | Adjusts inductive reactance | Minimizes reflected power back to the magnetron |

| Sliding Short | Modifies electrical phase | Aligns source and load impedance for maximum absorption |

| Impedance Matching | Synchronizes source/load | Enables temperatures of 1000°C+ at low input power |

| Waveguide Control | Energy path optimization | Ensures energy is used for reaction, not dissipated as loss |

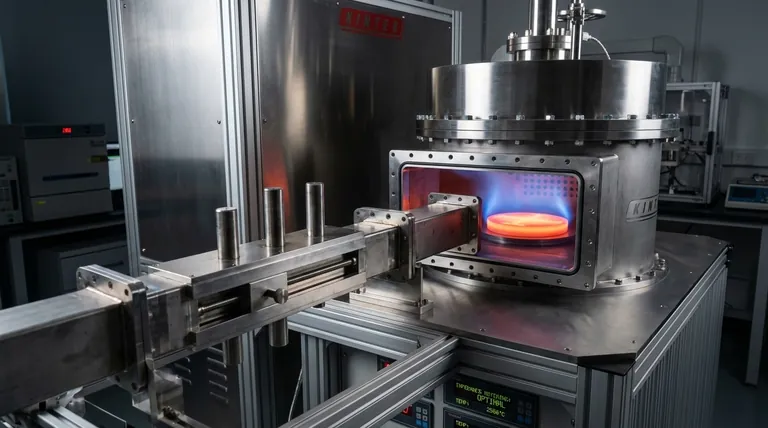

Optimize Your Microwave Processing with KINTEK

Don’t let reflected power compromise your research. KINTEK’s advanced microwave systems, backed by expert R&D and manufacturing, provide the precision impedance matching necessary for high-efficiency carbothermic reduction. Whether you require Muffle, Tube, Rotary, Vacuum, or CVD systems, our lab high-temp furnaces are fully customizable to meet your unique thermal requirements.

Ready to achieve several thousand degrees with maximum energy efficiency? Contact us today to discuss your custom furnace needs!

Visual Guide

References

- Ansan Pokharel, Terence Musho. Microwave-assisted recycling of tantalum and manganese from end-of-life tantalum capacitors. DOI: 10.1038/s41598-025-96574-7

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor

- Cylindrical Resonator MPCVD Machine System for Lab Diamond Growth

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- What is the function of high-purity graphite crucibles in Al-Cu-Mn master alloy prep? Ensure Chemical Purity

- Why is a high-purity Alumina (Al2O3) tube selected as the gas lance? Durable 1600°C Hydrogen Injection Solutions

- What factors influence the lifespan of alumina ceramic furnace tubes? Maximize Durability and Performance

- What is the function of condensers and cold traps in VEA? Master Efficient Reagent Recovery and Closed-Loop Success

- What is the role of a BN crucible in Ca0.5Sr0.5AlSiN3:Eu2+ synthesis? Achieve High-Purity Nitride Phosphors

- What is the function of vacuum systems and sealing connectors? Mastering Pure and Controlled Chemical Environments

- Why is a high-pressure MFC necessary for CHP systems? Achieve Precision in Catalytic Hydropyrolysis Data

- What factors should be considered when selecting a laboratory furnace? Ensure Optimal Performance and Safety