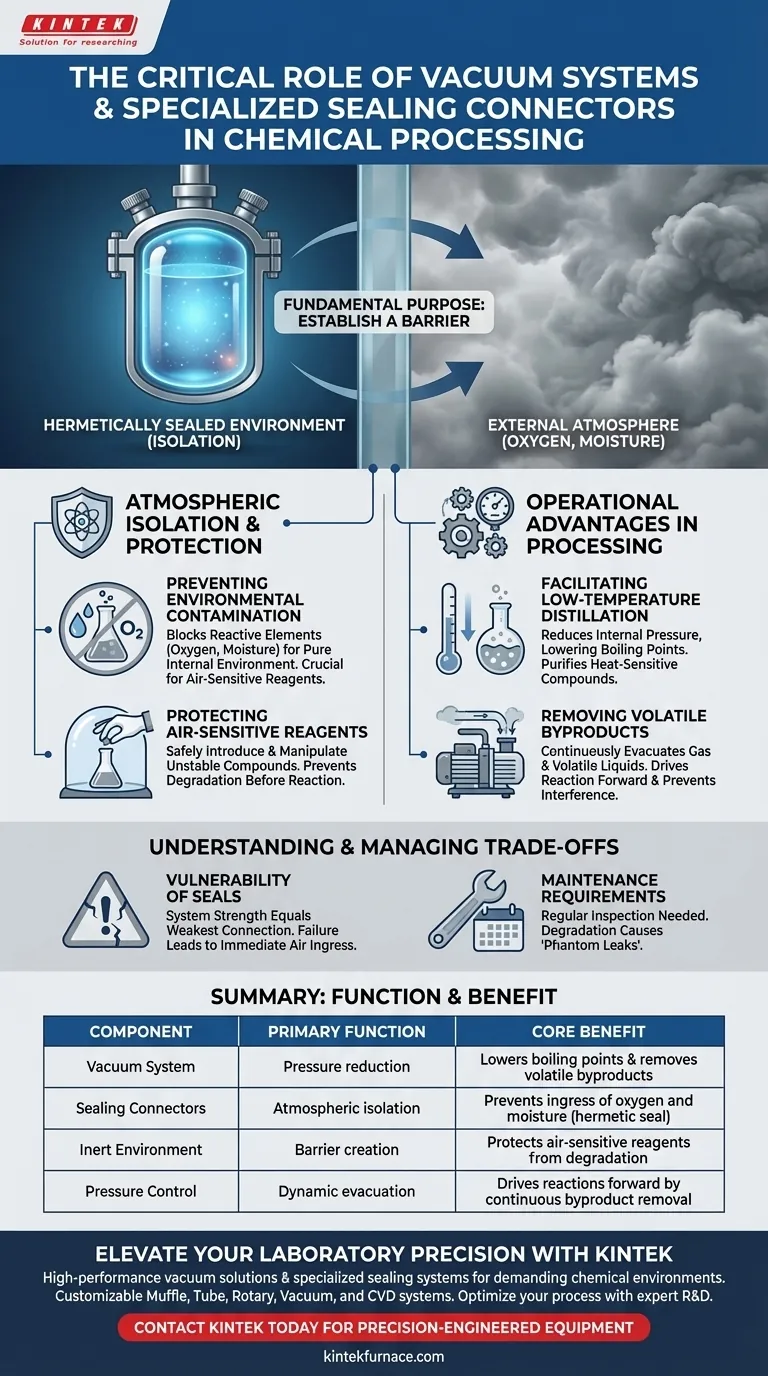

Vacuum systems and specialized sealing connectors serve one fundamental purpose: to establish a hermetically sealed environment that is completely isolated from the external atmosphere. This isolation is the prerequisite for manipulating air-sensitive reagents, efficiently removing volatile byproducts, and performing distillations at reduced temperatures without the risk of environmental contamination.

The core value of these systems is prevention and control. By effectively blocking oxygen and moisture, they transform an unpredictable open system into a controlled environment where chemical processes occur exactly as designed.

The Critical Role of Atmospheric Isolation

The primary function of these components is to create a barrier between the chemical reaction and the ambient environment. This isolation is not merely a safety precaution; it is often a chemical necessity.

Preventing Environmental Contamination

The atmosphere is filled with reactive elements, primarily oxygen and moisture.

If these elements enter a reaction vessel, they can cause immediate experimental failure. Specialized sealing connectors ensure that the internal environment remains pure.

Protecting Air-Sensitive Reagents

Many sophisticated chemical syntheses utilize reagents that degrade or combust upon contact with air.

Vacuum systems allow chemists to introduce and manipulate these unstable compounds safely. Without a robust seal, these reagents would be rendered useless before the reaction even begins.

Operational Advantages in Chemical Processing

Beyond simple isolation, vacuum systems actively assist in the mechanics of chemical processing. They alter the physical conditions within the vessel to facilitate specific outcomes.

Facilitating Low-Temperature Distillation

Vacuum systems reduce the internal pressure of the reaction vessel.

This pressure drop significantly lowers the boiling point of liquids. This allows for low-temperature distillation, which is crucial for purifying compounds that would decompose under high heat.

Removing Volatile Byproducts

Chemical reactions often generate gas or volatile liquids as byproducts.

A functioning vacuum system continuously evacuates these byproducts. Removing them drives the reaction forward and prevents them from interfering with the final product.

Understanding the Trade-offs

While vacuum systems and specialized seals are essential, they introduce specific complexities that must be managed.

The Vulnerability of Seals

The entire system is only as strong as its weakest connection.

If a specialized sealing connector fails or is improperly seated, the vacuum is broken. This leads to immediate ingress of air, potentially ruining the batch or creating a safety hazard.

Maintenance Requirements

Maintaining a perfect vacuum requires diligence.

Seals and connectors degrade over time and require regular inspection. Neglecting maintenance can lead to "phantom leaks" that make reproducible atmospheric conditions impossible to achieve.

Ensuring Process Integrity

To maximize the effectiveness of your vacuum systems and connectors, align your equipment choice with your specific chemical goals.

- If your primary focus is Handling Air-Sensitive Reagents: Prioritize high-integrity sealing connectors to ensure zero ingress of oxygen or moisture.

- If your primary focus is Efficiency and Speed: Ensure your vacuum pump capacity is matched to the system volume to rapidly remove volatile byproducts.

- If your primary focus is Thermal Sensitivity: Focus on system tightness to maintain deep vacuum levels, ensuring distillation occurs at the lowest possible temperature.

Success in these processes ultimately depends on the rigorous exclusion of the outside world to maintain specific, pre-set atmospheric conditions.

Summary Table:

| Component | Primary Function | Core Benefit in Chemical Processing |

|---|---|---|

| Vacuum System | Pressure reduction | Lowers boiling points for distillation & removes volatile byproducts |

| Sealing Connectors | Atmospheric isolation | Prevents ingress of oxygen and moisture (hermetic seal) |

| Inert Environment | Barrier creation | Protects air-sensitive reagents from degradation or combustion |

| Pressure Control | Dynamic evacuation | Drives reactions forward by continuous byproduct removal |

Elevate Your Laboratory Precision with KINTEK

Don’t let atmospheric contamination compromise your research integrity. KINTEK provides high-performance vacuum solutions and specialized sealing systems designed for the most demanding chemical environments.

Backed by expert R&D and world-class manufacturing, we offer a comprehensive range of Muffle, Tube, Rotary, Vacuum, and CVD systems, along with other lab high-temperature furnaces—all fully customizable to your unique specifications.

Ready to optimize your process? Contact us today to discover how KINTEK’s precision-engineered equipment can enhance your lab's efficiency and experimental reproducibility.

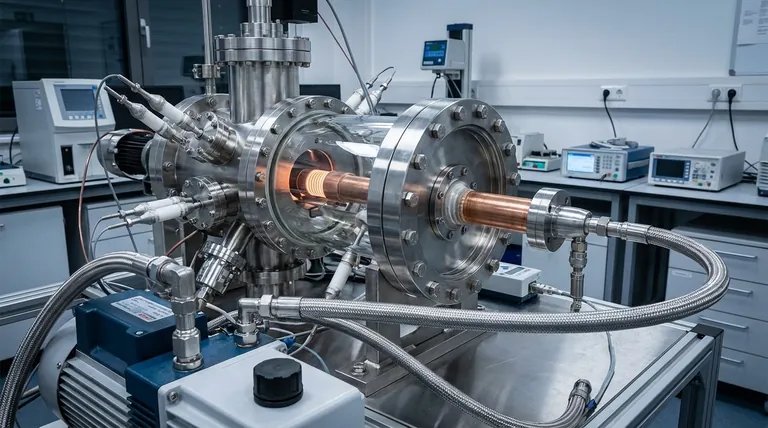

Visual Guide

References

- Nidhi Kushwaha, Kamal Kishore Pant. One‐Pot Microwave Assisted Etherification of Fructose to Sustainable Liquid Fuel Over TiS<sub>2</sub> Catalyst. DOI: 10.1002/cctc.202500504

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Ultra Vacuum Electrode Feedthrough Connector Flange Power Lead for High Precision Applications

- Stainless Steel Quick Release Vacuum Chain Three Section Clamp

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

People Also Ask

- What is the specific purpose of a Boron Nitride (BN) furnace lid? Protecting Molten Steel Purity

- What types of trays are compatible with SiC heating elements? Choose Graphite or Composite Ceramics for Thermal Shock Resistance

- How do carbon composite conveyor belts affect brazing filler metal spreading? Achieve Precision Joint Stability

- Why are high-purity graphite crucibles with lids used for ilmenite reduction? Control Your Micro-Reducing Atmosphere

- How do repeat sintering processes and specialized sintering molds address the technical challenges of manufacturing oversized flywheel rotor components? Expand Scale and Integrity

- Why use high-alumina (Alundum) crucibles for monazite glass-ceramic synthesis? Ensure Purity in High-Heat Research

- How does a vacuum pump facilitate the synthesis process of rare earth-based halide electrolytes? Boost Chemical Purity

- Why use a fusion furnace and platinum crucibles for XRF analysis of magnesium slag? Ensure Accurate Results