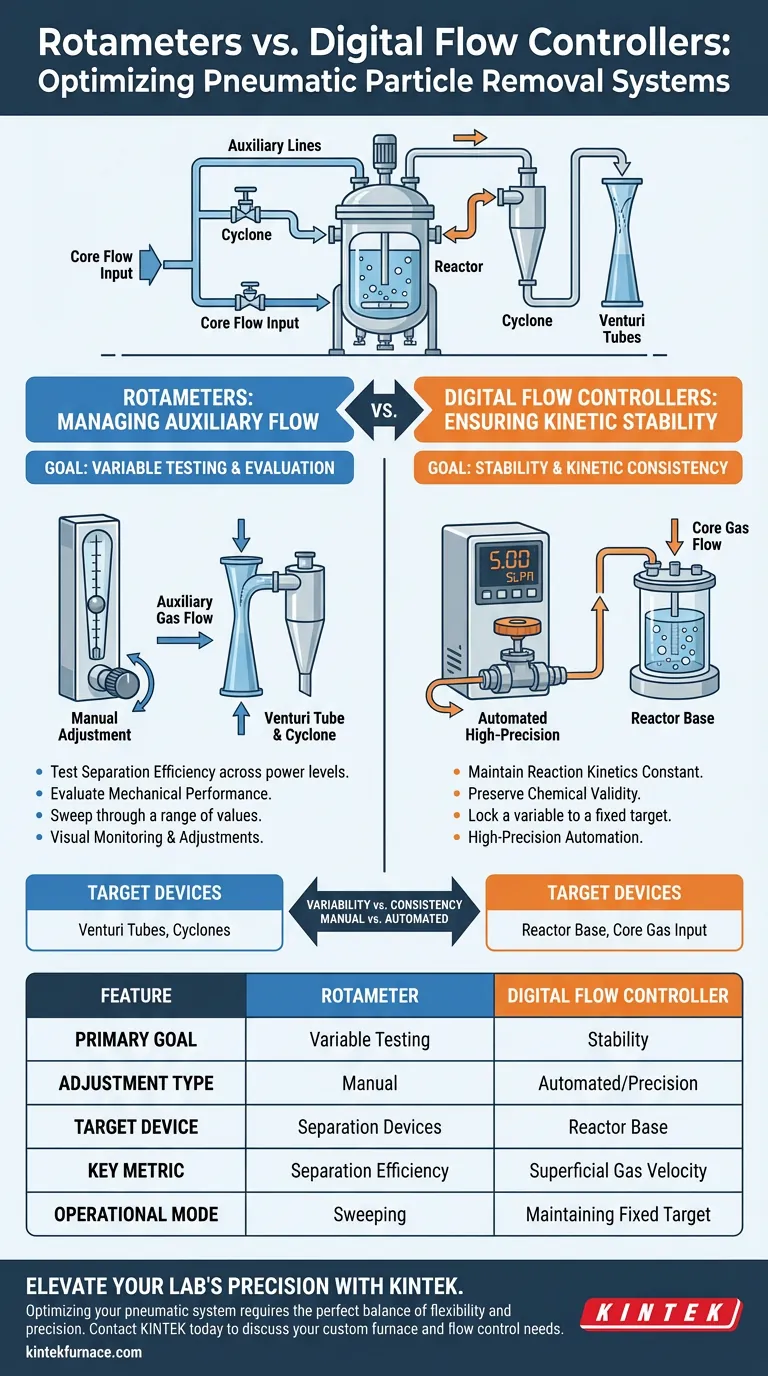

In pneumatic particle removal systems, rotameters and digital flow controllers serve opposite operational goals: variability for testing versus stability for reacting. Rotameters are used to manually adjust auxiliary gas flow to evaluate how removal devices perform under different power levels. Digital flow controllers are utilized to rigorously maintain the core gas flow to ensure reaction kinetics remain constant.

The fundamental difference is that rotameters facilitate variable testing of separation efficiency, whereas digital flow controllers ensure constant conditions for accurate reaction kinetics.

Managing Auxiliary Flow with Rotameters

The Role of Performance Evaluation

Rotameters are primarily assigned to the auxiliary gas flow lines. Their main function is to allow operators to manually adjust and monitor the flow rate entering removal devices.

Testing Separation Efficiency

This manual adjustment is critical for evaluating separation performance. By varying the flow via the rotameter, researchers can test how effective the system is at removing particles across different pneumatic power levels.

Target Devices

These instruments specifically regulate flow entering separation components, such as Venturi tubes or cyclones. The goal is to isolate the variables affecting the physical removal of particles rather than the chemical reaction itself.

Ensuring Kinetic Stability with Digital Flow Controllers

The Role of Core Process Control

Digital flow controllers are assigned to the core gas flow injected at the bottom of the reactor. Unlike the rotameter, which is used to sweep through different values, the digital controller is set to a specific, fixed target.

Maintaining Reaction Kinetics

The primary purpose here is to ensure that reaction kinetic conditions remain unchanged throughout the experiment. Precision is required to prevent fluctuations that could skew the chemical data.

Controlling Superficial Gas Velocity

Specifically, these controllers maintain the flow rate required for consistent bubbling behavior. This ensures that parameters such as superficial gas velocity remain constant, providing a stable baseline for the experiment.

Operational Distinctions and Trade-offs

Variability vs. Consistency

The choice of instrument reflects the need for the variable. Use rotameters when the objective is to sweep through a range of values to test mechanical efficiency (separation). Use digital controllers when the objective is to lock a variable to preserve chemical validity (kinetics).

Manual Monitoring vs. Automated Precision

Rotameters offer visual monitoring for adjustments, which is sufficient for auxiliary evaluations. Digital flow controllers offer the high-precision automation necessary for core reactor conditions, where even minor deviations can alter the bubbling regime and invalidate kinetic data.

Making the Right Choice for Your Goal

To ensure the integrity of your pneumatic removal system data, apply the instruments based on the specific zone of the reactor:

- If your primary focus is testing separation devices (Cyclones/Venturi): Rely on rotameters to vary the auxiliary flow and measure efficiency changes across different power levels.

- If your primary focus is preserving reaction data: Rely on digital flow controllers to lock in the core flow rate and guarantee constant superficial gas velocity.

By isolating the auxiliary testing variables from the core kinetic constants, you ensure accurate characterization of the system's performance.

Summary Table:

| Feature | Rotameter (Auxiliary Flow) | Digital Flow Controller (Core Flow) |

|---|---|---|

| Primary Goal | Variable Testing & Evaluation | Stability & Kinetic Consistency |

| Adjustment Type | Manual | Automated / High-Precision |

| Target Device | Venturi tubes, Cyclones | Reactor Base / Core Gas Input |

| Key Metric | Separation Efficiency | Superficial Gas Velocity |

| Operational Mode | Sweeping through values | Maintaining a fixed target |

Elevate Your Lab's Precision with KINTEK

Optimizing your pneumatic particle removal system requires the perfect balance of manual flexibility and automated precision. KINTEK provides the high-performance laboratory equipment necessary to achieve both.

Backed by expert R&D and manufacturing, KINTEK offers a comprehensive range of Muffle, Tube, Rotary, Vacuum, and CVD systems, along with other lab high-temperature furnaces—all fully customizable to meet your unique research needs. Whether you are testing separation efficiency in cyclones or maintaining strict reaction kinetics, our specialized systems deliver the reliability your data deserves.

Ready to upgrade your laboratory capabilities? Contact us today to discuss your custom furnace and flow control needs!

Visual Guide

References

- Zachary Cooper-Baldock, Mehdi Jafarian. Preliminary Evaluation of Methods for Continuous Carbon Removal from a Molten Catalyst Bubbling Methane Pyrolysis Reactor. DOI: 10.3390/en17020290

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Ultra-High Vacuum Flange Aviation Plug Glass Sintered Airtight Circular Connector for KF ISO CF

- CF KF Flange Vacuum Electrode Feedthrough Lead Sealing Assembly for Vacuum Systems

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- Electric Rotary Kiln Pyrolysis Furnace Plant Machine Small Rotary Kiln Calciner

- Ultra High Vacuum Observation Window KF Flange 304 Stainless Steel High Borosilicate Glass Sight Glass

People Also Ask

- What is the function of a high alumina crucible in chloride salt purification? Protect Purity and Thermal Stability

- What are the key properties of alumina ceramic furnace tubes? Discover Their High-Temp and Chemical Resistance

- What are the advantages of high-temperature BSE detectors? Unlock Real-Time Compositional Analysis up to 1000°C

- What is the function of a vacuum pump in tantalum capacitor recycling? Optimize Purity and Speed

- Why is an alumina crucible used for vacuum carbothermal reduction? Ensure Purity at 1723 K

- What is the role of a laboratory oven in the pre-treatment of Date Palm Stones? Enhance Torrefaction & Grinding Efficiency

- What role do graphite molds play in the Spark Plasma Sintering (SPS)? Enhance Alumina Composite Performance

- What is the specific significance of using high-purity corundum crucibles in oxidation weight gain experiments?