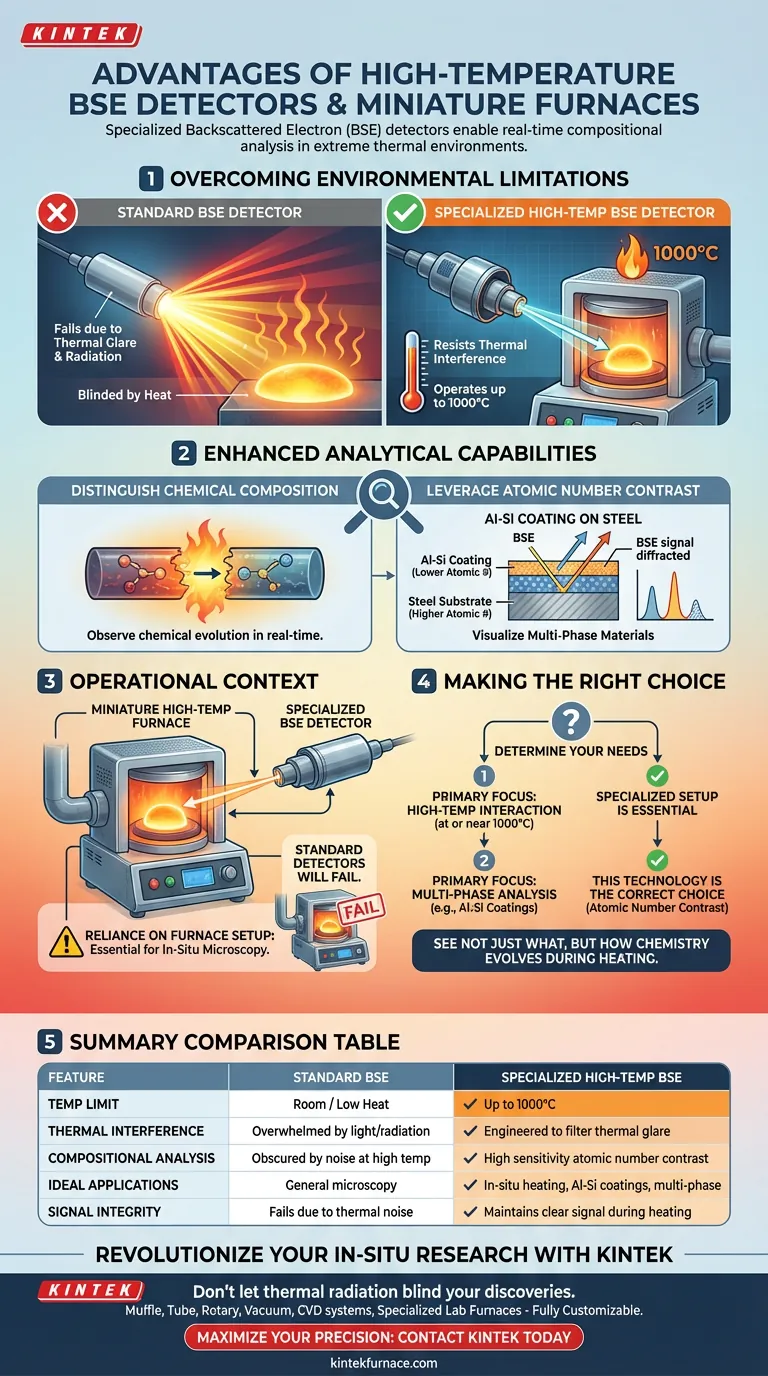

Specialized high-temperature Backscattered Electron (BSE) detectors provide the crucial ability to perform compositional analysis in environments that would blind or damage standard equipment. By effectively resisting the intense thermal radiation and light emitted by heating stages, these detectors enable the observation of chemical changes in materials at temperatures up to 1000°C.

Standard BSE detectors cannot function in high-heat environments because they are overwhelmed by thermal light and radiation. Specialized high-temperature detectors solve this by filtering out this interference, allowing for the precise visualization of material composition via atomic number contrast in real-time.

Overcoming Environmental Limitations

Resisting Thermal Interference

The primary advantage of these specialized detectors is their resistance to the harsh environment inside a miniature high-temperature furnace.

Standard detectors are sensitive to the light and heat radiation emitted by hot samples, which creates noise that obscures the image. Specialized detectors are engineered to ignore this thermal "glare," maintaining signal integrity.

Operating at Extreme Temperatures

These detectors are capable of functioning effectively at temperatures as high as 1000°C.

This capability allows researchers to observe materials under conditions that mimic real-world processing or operating environments, rather than relying solely on post-mortem analysis at room temperature.

Enhanced Analytical Capabilities

Distinguishing Chemical Composition

The core value of using a BSE detector is its ability to reveal differences in chemical composition.

Because specialized detectors maintain their sensitivity at high heat, they allow you to distinguish between different chemical phases within a sample while it is being heated.

Leveraging Atomic Number Contrast

These detectors utilize atomic number contrast to visualize multi-phase materials.

This is particularly valuable for complex samples, such as aluminum-silicon coatings on steel. The detector can clearly differentiate between the coating and the substrate based on their atomic weight, even as the sample undergoes thermal stress.

Understanding the Operational Context

Reliance on Miniature Furnaces

These detectors are specifically optimized for use in conjunction with miniature high-temperature furnaces.

They are part of an integrated system designed for in-situ microscopy. Trying to use them without the appropriate furnace setup, or attempting to use standard detectors in this specific furnace environment, will result in operational failure or poor data quality.

The "Standard" Gap

It is critical to note that standard BSE detectors will fail under these specific conditions.

There is no middle ground here; if your experiment requires reaching 1000°C, a standard detector is not a viable option as it cannot handle the associated thermal radiation.

Making the Right Choice for Your Research

To determine if this technology fits your experimental needs, consider your specific analytical goals:

- If your primary focus is high-temperature interaction: This setup is essential for observing materials at or near 1000°C, as standard gear will not function.

- If your primary focus is multi-phase analysis: This technology is the correct choice for distinguishing complex layers, such as aluminum-silicon coatings, via atomic number contrast during heating.

By pairing specialized BSE detectors with miniature furnaces, you unlock the ability to see not just what a material looks like after heating, but how its chemistry evolves during the process.

Summary Table:

| Feature | Standard BSE Detectors | Specialized High-Temp BSE Detectors |

|---|---|---|

| Temperature Limit | Room Temp / Low Heat | Up to 1000°C |

| Thermal Interference | Overwhelmed by light/radiation | Engineered to filter thermal glare |

| Compositional Analysis | Obscured by noise at high temp | High sensitivity atomic number contrast |

| Ideal Applications | General microscopy | In-situ heating, Al-Si coatings, multi-phase analysis |

| Signal Integrity | Fails due to thermal noise | Maintains clear signal during heating |

Revolutionize Your In-Situ Materials Research with KINTEK

Don't let thermal radiation blind your discoveries. KINTEK provides the specialized equipment needed to observe material evolution in real-time. Backed by expert R&D and manufacturing, we offer a comprehensive range of Muffle, Tube, Rotary, Vacuum, and CVD systems, along with specialized lab high-temp furnaces—all fully customizable to meet your unique research needs.

Whether you are analyzing complex aluminum-silicon coatings or studying multi-phase thermal stress, our team is ready to help you configure the perfect high-temperature setup.

Maximize your lab's analytical precision—contact KINTEK today to discuss your custom solution!

Visual Guide

References

- Jérôme Mendonça, Renaud Podor. Development of a microfurnace dedicated to <i>in situ</i> scanning electron microscope observation up to 1300 °C. III. <i>In situ</i> high temperature experiments. DOI: 10.1063/5.0207477

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- What is the function of high-purity alumina crucibles? Protect Samples and Furnaces During Oxide Calcination

- How does the integration of digital control panels and safety devices enhance industrial electric furnace operation?

- What role does specialized graphite adhesive play? Expert Bonding Solutions for High-Temp Systems

- What are the thermal properties of alumina tubes? Discover Their High-Temp Durability and Stability

- What are the advantages of using high-purity quartz tubes as reaction vessels? Unlock Active Flux Synthesis

- Why are high-purity alumina tubes and crucibles preferred for high-temperature smelting? Ensure Maximum Sample Purity

- What is the function of a precision oven in drying resin-impregnated wood? Optimize Your Bonding & Structural Integrity

- How do 15x80mm technical openings and seals boost electric furnace efficiency? Maximize Thermal Performance Today