High-purity alumina crucibles function as the primary barrier protecting both your sample and your equipment during high-temperature calcination. They serve as chemically inert carriers that isolate reactive multi-component oxides, specifically preventing the escape of volatile alkali elements and blocking contamination from the furnace environment.

The central role of the crucible is physical and chemical isolation. By effectively containing corrosive agents like Lithium or Sodium, these vessels ensure the phase purity of your target product while simultaneously preventing your sample from reacting with the furnace lining.

The Mechanics of Sample Isolation

Chemical Inertness at High Heat

The fundamental function of high-purity alumina is to provide a stable environment for reactions. These crucibles maintain excellent thermal stability and chemical inertness, making them ideal carriers for sintering and calcination processes.

Containing Volatile Elements

During the calcination of multi-component oxides, particularly those containing alkali metals (such as Lithium, Sodium, or Potassium), containment is critical.

These elements often have low melting points and can be highly corrosive. The alumina crucible effectively effectively holds these compounds, preventing them from volatilizing and damaging the furnace body.

Preventing Furnace Interaction

At elevated temperatures, there is a risk of chemical reaction between the sample and the furnace lining.

By acting as a physical shield, the crucible prevents the sample from adhering to or reacting with the furnace interior. This isolation is crucial for preserving the mechanical and chemical integrity of both the sample and the heating element.

Preserving Material Integrity

Ensuring Phase Purity

The ultimate goal of using high-purity alumina is to guarantee the quality of the final product.

By eliminating cross-contamination, these crucibles ensure the phase purity of complex materials, such as quaternary phosphates or borates.

Protecting Dielectric Performance

For advanced ceramics, external impurities can drastically alter performance metrics.

Isolating the ceramic green bodies ensures that external contaminants do not negatively impact sensitive properties, such as microwave dielectric loss performance.

Understanding the Operational Limits

Temperature Constraints

While high-purity alumina is robust, it is essential to adhere to specific temperature ranges to maintain inertness.

Primary usage often occurs during air atmosphere sintering up to 1000°C, though specific applications can utilize these crucibles effectively at temperatures as high as 1400°C.

Reactivity Factors

"Inert" is a relative term. While alumina is excellent for containing alkali metals, the specific chemistry of your multi-component oxide matters.

You must ensure that your specific oxide mixture does not have a unique affinity for reacting with alumina at your target temperature, although for most standard alkali compounds, it remains the standard protective vessel.

Making the Right Choice for Your Goal

When selecting a vessel for calcination, consider your primary objective:

- If your primary focus is Equipment Protection: High-purity alumina is essential for containing corrosive alkali metals (Li, Na, K) to prevent damage to your furnace body.

- If your primary focus is Data Integrity: The crucible is required to prevent cross-contamination from the furnace lining, ensuring the phase purity and dielectric accuracy of your sample.

High-purity alumina offers the necessary balance of thermal stability and chemical isolation to secure both your equipment and your scientific results.

Summary Table:

| Feature | Function in Calcination | Benefit to User |

|---|---|---|

| Chemical Inertness | Prevents reactions between sample & crucible | Ensures high phase purity |

| Alkali Containment | Blocks volatile Li, Na, K from escaping | Protects furnace heating elements |

| Physical Barrier | Separates sample from furnace lining | Prevents cross-contamination |

| Thermal Stability | Maintains integrity up to 1400°C | Reliable performance in high-heat cycles |

| Dielectric Protection | Isolates green bodies from impurities | Maintains sensitive material performance |

Optimize Your Calcination Process with KINTEK

Don't compromise your material integrity or risk expensive furnace damage. KINTEK provides premium high-purity alumina crucibles designed for the most demanding multi-component oxide calcinations.

Backed by expert R&D and world-class manufacturing, we offer a full range of Muffle, Tube, Rotary, Vacuum, and CVD systems, all of which can be customized to your specific laboratory requirements. Whether you are sintering advanced ceramics or processing corrosive phosphates, our technical team is ready to help you select the perfect thermal solution.

Contact KINTEK Today for a Custom Quote

References

- Jiadong Chen, Wenhao Sun. Navigating phase diagram complexity to guide robotic inorganic materials synthesis. DOI: 10.1038/s44160-024-00502-y

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

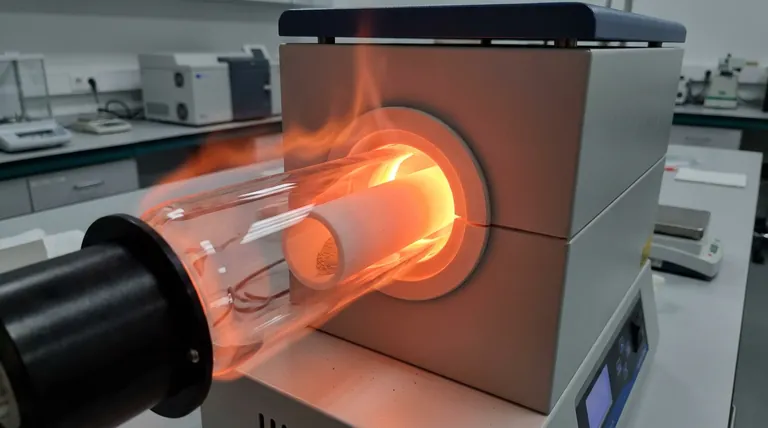

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1200℃ Muffle Oven Furnace for Laboratory

People Also Ask

- Why are high-purity alumina crucibles used for containing molten high-silicon steel? Ensure Purity & Thermal Stability

- What material are quartz tubes made from and what temperature can they withstand? Discover High-Temp Solutions for Your Lab

- What roles do high-purity graphite molds perform in A357 sintering? Enhancing Aluminum Matrix Composite Performance

- How does a heating stage contribute to the quality of multi-material 3D printing? Optimize Precision and Stability

- What role do substrate heaters play in Ga2O3:Er thin films? Unlock Crystalline Beta-Phase Transitions

- Why is a graphite thermal baffle necessary for thermal field control? Master Single-Crystal Growth Quality

- What are the functions of high-purity, high-strength graphite molds in SPS? Optimize Al2O3-TiC Ceramic Sintering

- What is the purpose of using integrated temperature controllers for CuInP2S6? Master CIPS Electrical Characterization