In essence, quartz tubes are made from high-purity fused quartz, a material that allows them to reliably withstand continuous operating temperatures up to 1200°C (2192°F). Depending on the specific grade and operating conditions, their tolerance can be even higher for short durations.

The true value of quartz is not just its high-temperature tolerance but its unique combination of thermal shock resistance, chemical purity, and optical clarity, making it the default choice for demanding scientific and industrial processes.

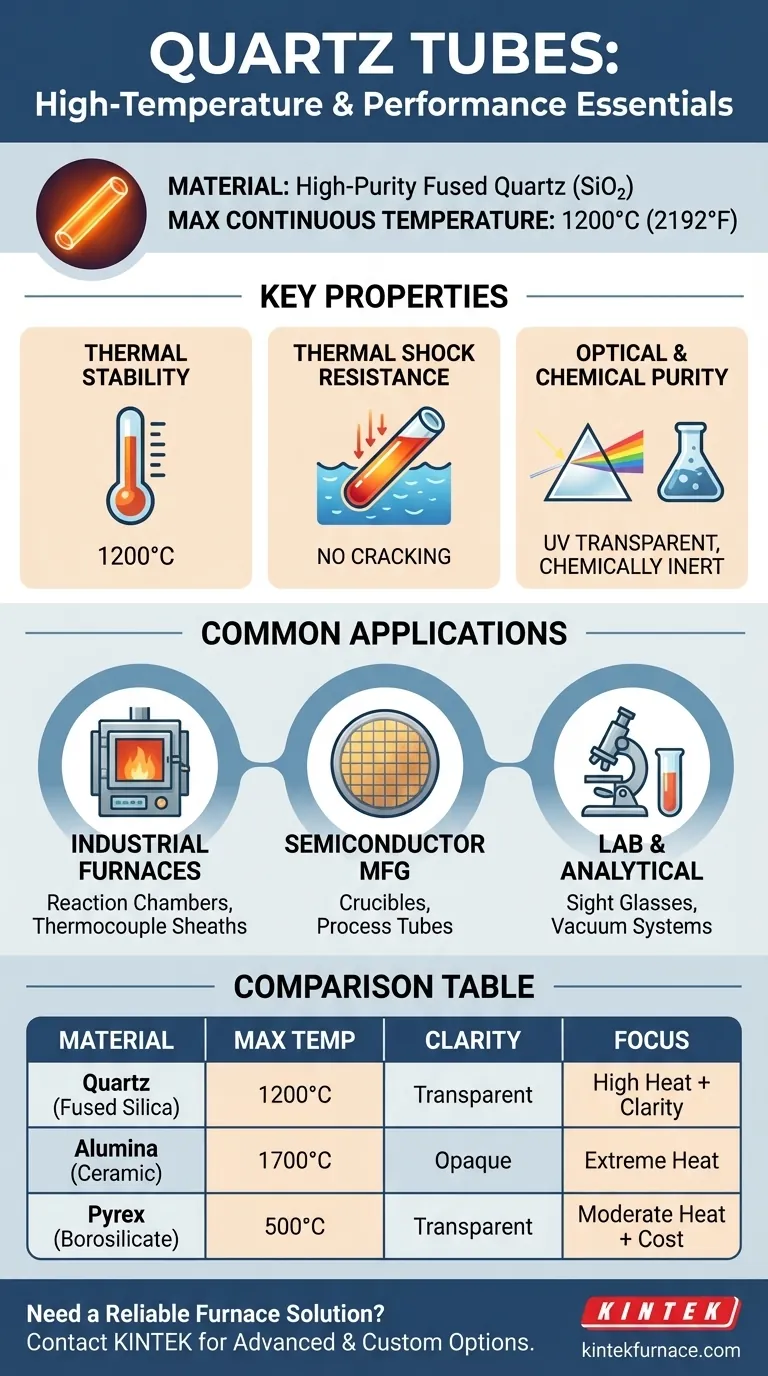

The Properties That Make Quartz Essential

Understanding why quartz is specified for high-temperature work requires looking beyond its melting point. Its performance is a result of several key material properties working in concert.

High-Purity Fused Quartz

Quartz tubes are not made from ordinary glass. They are constructed from fused quartz or fused silica, which is silicon dioxide (SiO₂) in its amorphous, non-crystalline form.

This high-purity composition is critical for preventing contamination in sensitive processes like semiconductor manufacturing or chemical analysis.

Exceptional Thermal Stability

The most cited feature is the ability to operate continuously at temperatures up to 1200°C. Above this point, the material begins to soften and may deform under its own weight, a process known as devitrification.

Resistance to Thermal Shock

Perhaps its most remarkable property is an extremely low coefficient of thermal expansion. This allows a quartz tube to withstand rapid and extreme temperature changes without cracking.

You can, for example, heat a quartz tube to red-hot and then plunge it into cold water without it shattering. This is impossible for most other ceramics or glasses.

Optical and Chemical Purity

Fused quartz is transparent to a wide spectrum of light, including ultraviolet (UV) wavelengths, making it essential for UV lamps and specific photochemical reactions.

Furthermore, it is chemically inert to most acids and compounds, ensuring that the tube itself does not react with the substances being heated inside it.

Common Applications in Industry and Research

The unique properties of quartz make it indispensable in a variety of high-stakes environments.

In Industrial Furnaces

Quartz tubes are frequently used as reaction chambers in tube furnaces. Materials are placed inside the tube, which is then heated externally, allowing for processing in a controlled atmosphere.

They also serve as protective sheaths for thermocouples, shielding the sensitive temperature sensors from harsh chemical or high-temperature environments.

For Semiconductor Manufacturing

The electronics industry relies heavily on quartz for its extreme purity. It is used to create crucibles for growing silicon crystals and as process tubes for depositing thin films onto wafers.

In Laboratory and Analytical Settings

In research labs, quartz tubes function as sight glasses for observing high-temperature reactions, as components in vacuum systems due to their strength, and as cuvettes for spectrophotometry.

Understanding the Trade-offs and Alternatives

While quartz is a superior material, it is not the only option. The right choice depends on your specific temperature requirements and budget.

When Quartz is Overkill

For many general laboratory heating applications below 500°C (932°F), Pyrex (a type of borosilicate glass) is a perfectly suitable and more cost-effective alternative. However, Pyrex cannot handle the extreme temperatures or thermal shock that quartz can.

When Quartz Isn't Enough

For applications requiring continuous operating temperatures well above 1200°C, other ceramic materials are necessary.

Alumina (aluminum oxide) tubes are a common choice for temperatures up to 1700°C (3092°F). The primary trade-off is that alumina is opaque, so you lose the ability to visually monitor the process inside the tube.

Making the Right Choice for Your Application

Selecting the correct material is critical for the safety and success of your work. Base your decision on the maximum operating temperature and the need for visual access.

- If your primary focus is extreme heat (1200°C to 1700°C): Choose an Alumina tube, but be prepared for its opacity.

- If your primary focus is high heat (up to 1200°C) with optical clarity: Fused quartz is the definitive and correct choice for your application.

- If your primary focus is moderate heat (under 500°C) and cost efficiency: A Pyrex (borosilicate) tube is often the most practical solution.

Choosing the right material ensures the integrity of your experiment and the reliability of your results.

Summary Table:

| Property | Details |

|---|---|

| Material | High-purity fused quartz (SiO₂) |

| Max Continuous Temperature | Up to 1200°C (2192°F) |

| Key Features | Thermal shock resistance, chemical purity, optical clarity |

| Common Uses | Tube furnaces, semiconductor manufacturing, laboratory analysis |

Need a reliable high-temperature furnace solution for your lab? KINTEK offers advanced products like Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. With our strong R&D and deep customization capabilities, we can tailor solutions to meet your unique experimental needs. Contact us today to enhance your lab's performance and efficiency!

Visual Guide

Related Products

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What is the primary function of high-purity quartz sealed tubes? Master Sb-Te Alloy Synthesis with Precision Isolation

- What is the primary function of a vacuum-sealed quartz tube in MnBi2Te4 growth? Ensure High-Purity Crystal Synthesis

- How to clean a tube furnace? A Step-by-Step Guide to Safe and Effective Maintenance

- Why is a high-precision vacuum tube furnace essential for CVD graphene? Master Growth Control & Purity

- What is the function of high-vacuum encapsulated quartz tubes for Ce2(Fe, Co)17? Ensure Phase Purity and Stability