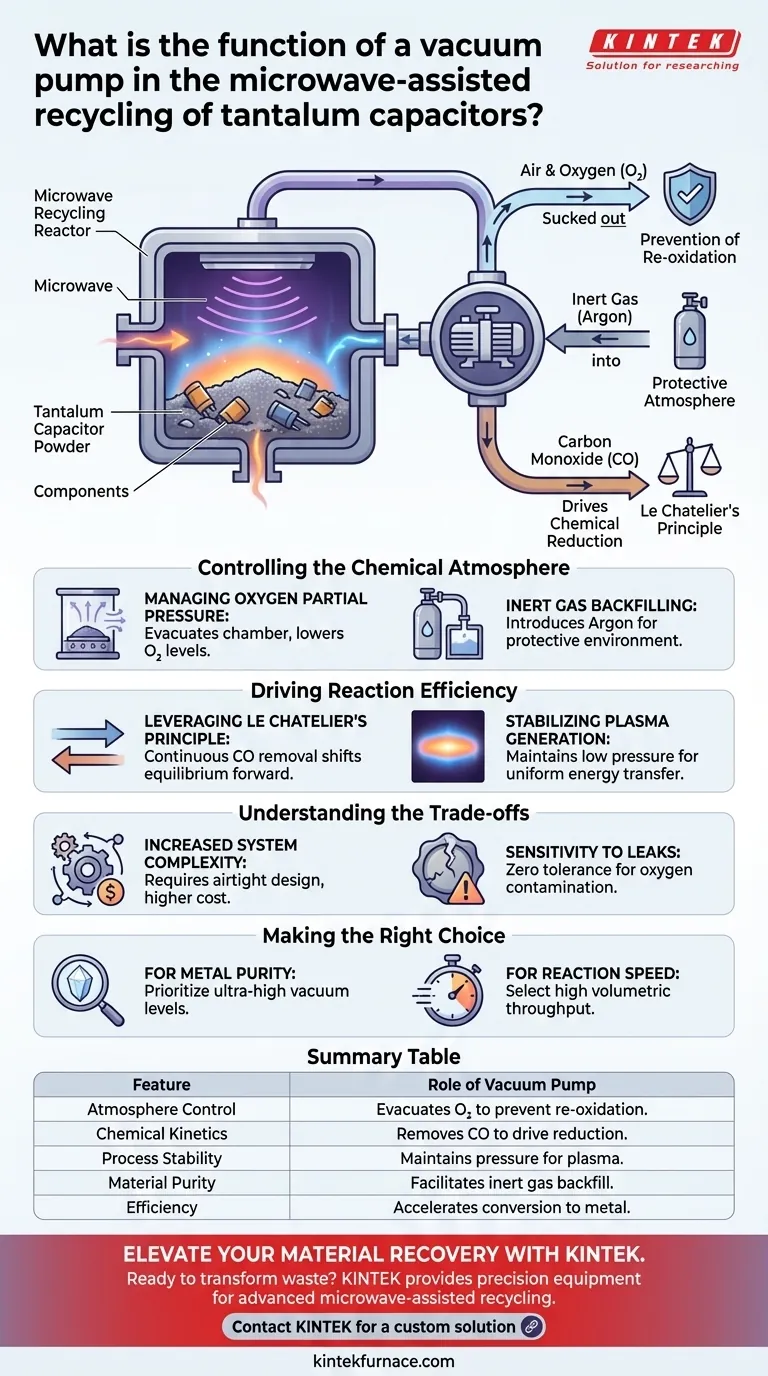

The primary function of a vacuum pump in microwave-assisted recycling is to rigorously control the reaction environment by managing internal pressure and gas composition. It eliminates atmospheric oxygen to prevent re-oxidation of the tantalum and actively drives the chemical reduction process by removing gaseous byproducts.

In microwave-assisted recycling, the vacuum pump acts as a reaction enabler: it ensures metal purity by removing air, stabilizes the heating plasma, and accelerates chemical reduction by extracting carbon monoxide.

Controlling the Chemical Atmosphere

The success of recycling tantalum capacitors hinges on preventing contamination during high-temperature processing. The vacuum pump is the critical component that establishes the necessary inert environment.

Managing Oxygen Partial Pressure

Tantalum is highly reactive with oxygen at high temperatures. The vacuum pump evacuates the reaction chamber to lower the oxygen partial pressure significantly.

Inert Gas Backfilling

Once the chamber is evacuated, the system is backfilled with inert gases, such as argon. The vacuum pump facilitates this exchange, creating a protective atmosphere that prevents the metal from oxidizing during the heating cycle.

Driving Reaction Efficiency

Beyond simple protection, the vacuum pump plays an active role in the chemical kinetics of the recycling process. It is essential for maintaining the thermodynamic conditions required for efficient reduction.

Leveraging Le Chatelier's Principle

The carbothermal reduction of tantalum oxide generates carbon monoxide (CO) gas as a byproduct. The vacuum pump continuously removes this gas, maintaining a low-pressure environment.

By extracting the product (CO) as it forms, the system utilizes Le Chatelier's principle to shift the chemical equilibrium. This drives the reduction reaction forward, ensuring a more complete and faster conversion of oxide to metal.

Stabilizing Plasma Generation

Microwave heating in this context often relies on the generation of plasma around the powder particles. A controlled low-pressure environment is required to initiate and sustain this plasma.

The vacuum pump maintains the specific pressure range needed to stabilize the plasma. This ensures uniform energy transfer to the tantalum powder, preventing hot spots or uneven processing.

Understanding the Trade-offs

While a vacuum system is essential for high-quality results, it introduces specific engineering challenges that must be managed.

Increased System Complexity

Integrating a vacuum pump requires a robust, airtight chamber design. This increases the initial capital cost and adds complexity to the mechanical design of the recycling reactor.

Sensitivity to Leaks

The reliance on low partial oxygen pressure means the system has zero tolerance for leaks. Even a microscopic breach in the vacuum seal can introduce enough oxygen to compromise the purity of the recycled tantalum.

Making the Right Choice for Your Goal

The specification of your vacuum system should align with your specific processing priorities.

- If your primary focus is Metal Purity: Prioritize a pump capable of achieving ultra-high vacuum levels to minimize oxygen partial pressure before argon backfilling.

- If your primary focus is Reaction Speed: Select a pump with high volumetric throughput to rapidly evacuate carbon monoxide and drive the reduction kinetics.

Mastering the pressure environment is the key to transforming waste capacitors into high-value, pure tantalum.

Summary Table:

| Feature | Role of Vacuum Pump in Recycling |

|---|---|

| Atmosphere Control | Evacuates oxygen to prevent tantalum re-oxidation. |

| Chemical Kinetics | Removes CO gas to drive reduction via Le Chatelier's Principle. |

| Process Stability | Maintains specific pressure ranges for stable plasma generation. |

| Material Purity | Facilitates inert gas backfilling (e.g., Argon) for a clean reaction. |

| Efficiency | Accelerates the conversion of tantalum oxide to pure metal powder. |

Elevate Your Material Recovery with KINTEK

Ready to transform waste into high-value tantalum? KINTEK provides the precision equipment necessary for advanced microwave-assisted recycling. Backed by expert R&D and manufacturing, we offer Muffle, Tube, Rotary, Vacuum, and CVD systems, all fully customizable to meet your unique laboratory and industrial high-temperature needs.

Maximize your purity and reaction efficiency today—Contact KINTEK for a custom solution!

Visual Guide

References

- Ansan Pokharel, Terence Musho. Microwave-assisted recycling of tantalum and manganese from end-of-life tantalum capacitors. DOI: 10.1038/s41598-025-96574-7

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- CF KF Flange Vacuum Electrode Feedthrough Lead Sealing Assembly for Vacuum Systems

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- 304 316 Stainless Steel High Vacuum Ball Stop Valve for Vacuum Systems

People Also Ask

- What are the main composition percentages of alumina tubes? Optimize Performance for High-Temperature Applications

- What functions do high-strength graphite molds serve in FAST? Optimize Titanium Alloy Consolidation Today

- What maintenance is required for a water circulating vacuum pump? Ensure Peak Performance and Longevity

- What is the temperature range for Laboratory Type Furnaces? Find Your Ideal Heat Solution

- Why use high-performance insulation bricks in radiant tube simulations? Ensure precision and industrial accuracy.

- What are the reasons for using high-purity alumina material for the reaction tubes in a Drop Tube Furnace? - Guide

- What is the role of a laboratory oven in the pre-treatment of Date Palm Stones? Enhance Torrefaction & Grinding Efficiency

- What customization options are available for laboratory furnaces? Tailor Your Furnace for Precise Thermal Control