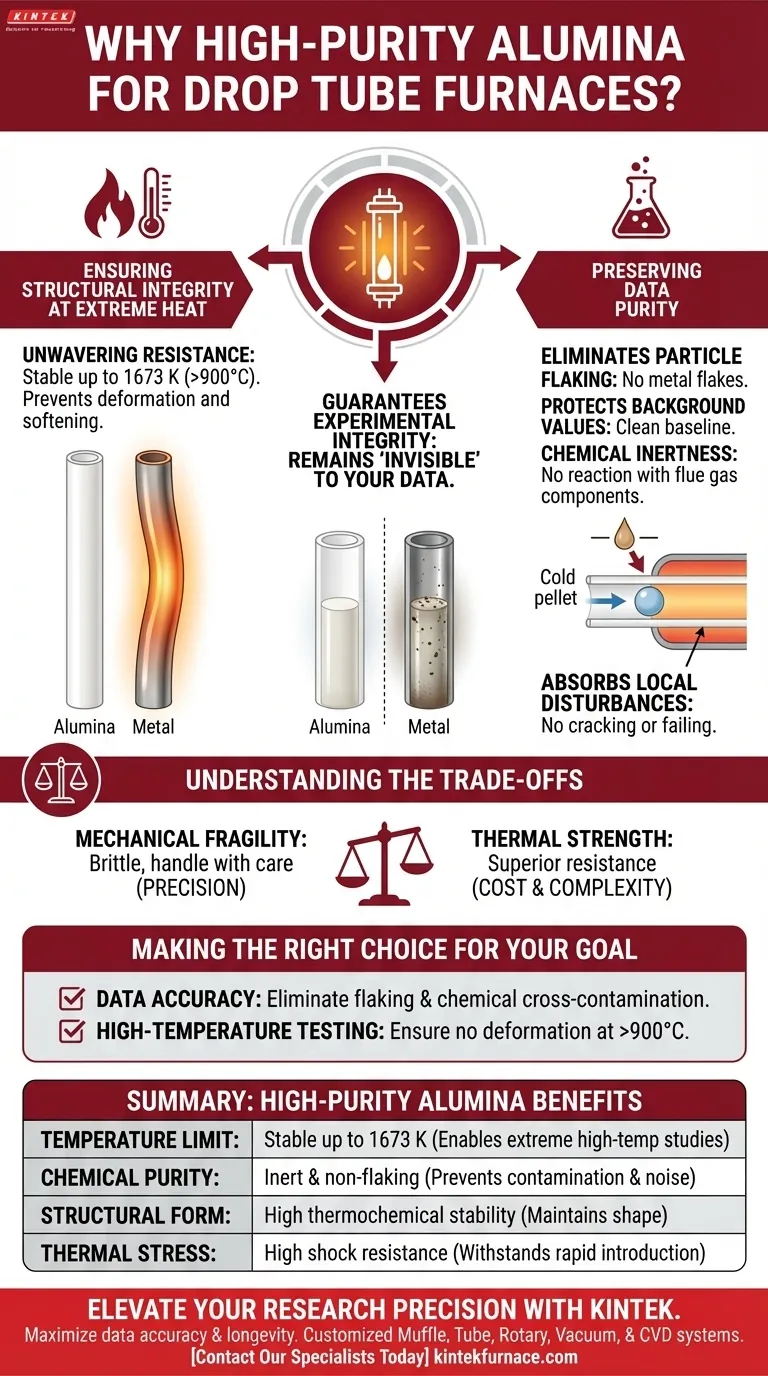

High-purity alumina is the material of choice for reaction tubes in Drop Tube Furnaces because it guarantees experimental integrity under harsh conditions. It offers a critical combination of stability at temperatures exceeding 900 °C (up to 1673 K), resistance to chemical interaction, and the durability to withstand the thermal shock of introducing cold samples into a hot zone.

The decisive advantage of high-purity alumina is its ability to remain "invisible" to your data. By preventing physical flaking and chemical reactions, it ensures your results reflect the sample properties, not equipment byproducts.

Ensuring Structural Integrity at Extreme Heat

Unwavering High-Temperature Resistance

Drop Tube Furnaces often operate at temperatures of 900 °C or significantly higher (up to 1673 K). High-purity alumina excels in these environments where other materials might fail.

Prevention of Deformation

At these elevated temperatures, many materials soften or warp. Alumina maintains excellent thermochemical stability, ensuring the tube retains its shape and structural integrity throughout the heating cycle.

Preserving Data Purity

Eliminating Particle Flaking

One of the most critical reasons for choosing alumina over metal is the prevention of contamination. Metal tubes frequently produce flaking particles when exposed to high heat.

protecting Background Values

These metal flakes can interfere with experimental background values, compromising data accuracy. High-purity alumina does not flake, ensuring a clean baseline for your experiments.

Chemical Inertness

Alumina acts as a neutral barrier. It does not react with flue gas components or combustion products, preventing chemical distortion of your results.

Managing Thermal Dynamics

Superior Thermal Shock Resistance

The operation of a Drop Tube Furnace involves a specific stressor: the introduction of materials (such as wood pellets) into the heated zone.

Withstanding Local Disturbances

This action creates immediate local thermal disturbances. Alumina's superior thermal shock resistance allows it to absorb this rapid temperature change without cracking or failing.

Understanding the Trade-offs

Mechanical Fragility vs. Thermal Strength

While alumina offers superior thermal resistance compared to metal, it lacks the ductility of metal alloys. It is mechanically brittle, meaning it requires careful handling during installation and maintenance to prevent physical breakage.

Cost and Complexity

High-purity ceramics are generally more specialized than standard metal tubes. While they extend service life by preventing corrosion and deformation, they represent a commitment to precision over ruggedness.

Making the Right Choice for Your Goal

- If your primary focus is Data Accuracy: Rely on high-purity alumina to eliminate the risk of metal flaking and chemical cross-contamination in your background values.

- If your primary focus is High-Temperature Testing: Utilize alumina to ensure the reaction tube does not deform or lose structural integrity at temperatures above 900 °C.

By choosing high-purity alumina, you are prioritizing the chemical and physical isolation necessary for valid scientific results.

Summary Table:

| Feature | High-Purity Alumina Benefit | Impact on Research |

|---|---|---|

| Temperature Limit | Stable up to 1673 K (1400°C+) | Enables extreme high-temp combustion studies |

| Chemical Purity | Inert & non-flaking material | Prevents sample contamination & background noise |

| Structural Form | High thermochemical stability | Maintains tube shape without warping or softening |

| Thermal Stress | High thermal shock resistance | Withstands rapid sample introduction without cracking |

Elevate Your Research Precision with KINTEK

Maximize your data accuracy and equipment longevity with KINTEK’s high-performance laboratory solutions. Backed by expert R&D and precision manufacturing, KINTEK offers a comprehensive range of Muffle, Tube, Rotary, Vacuum, and CVD systems, all of which can be customized with high-purity alumina components to meet your unique experimental needs.

Don't let equipment contamination compromise your results. Contact our specialists today to discuss how our customizable high-temperature furnaces can provide the chemical inertness and thermal stability your research demands.

Visual Guide

References

- Guillaume Gerandi, Valérie Tschamber. Particulate and gaseous emissions during combustion of wood pellets under low and high heating rates in a drop tube furnace. DOI: 10.2139/ssrn.5600417

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Magnesium Extraction and Purification Condensing Tube Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

People Also Ask

- Why is a high-purity Alumina (Al2O3) tube selected as the gas lance? Durable 1600°C Hydrogen Injection Solutions

- What is the function of a graphite crucible in iron ore softening tests? Simulate Blast Furnace Conditions Perfectly

- What role do quartz tubes and vacuum sealing play in synthesis? Master High-Reactivity Compounds like U0.92Mn3Si2C

- Why are high-purity zirconia grinding balls preferred over steel? Achieve Ultra-Pure Ceramic Grinding Results

- What are the functions of BN crucibles and embedding powders in Si3N4 sintering? Expert Guide to Material Stability

- What industries benefit from the use of alumina ceramic tubes? Essential for High-Temp, Corrosive Environments

- What role does a rotary evaporator play in microalgae-based nanomaterials? Protect Bio-Reductive Activity for Synthesis

- What is the function of a high-purity porcelain crucible? Expert Guide to Chromium-Doped Borosilicate Glass Preparation