For a typical lab-scale circulating water vacuum pump, the power consumption is 180W. This pump is designed to operate on standard electrical systems, with models available for either 110V (at 60Hz) or 220-240V (at 50/60Hz) single-phase power supplies.

While the 180W power rating is the direct answer, it's an electrical specification that results from the pump's mechanical performance. The crucial task is to understand how this power enables the flow rate, lift, and vacuum level required for your specific application.

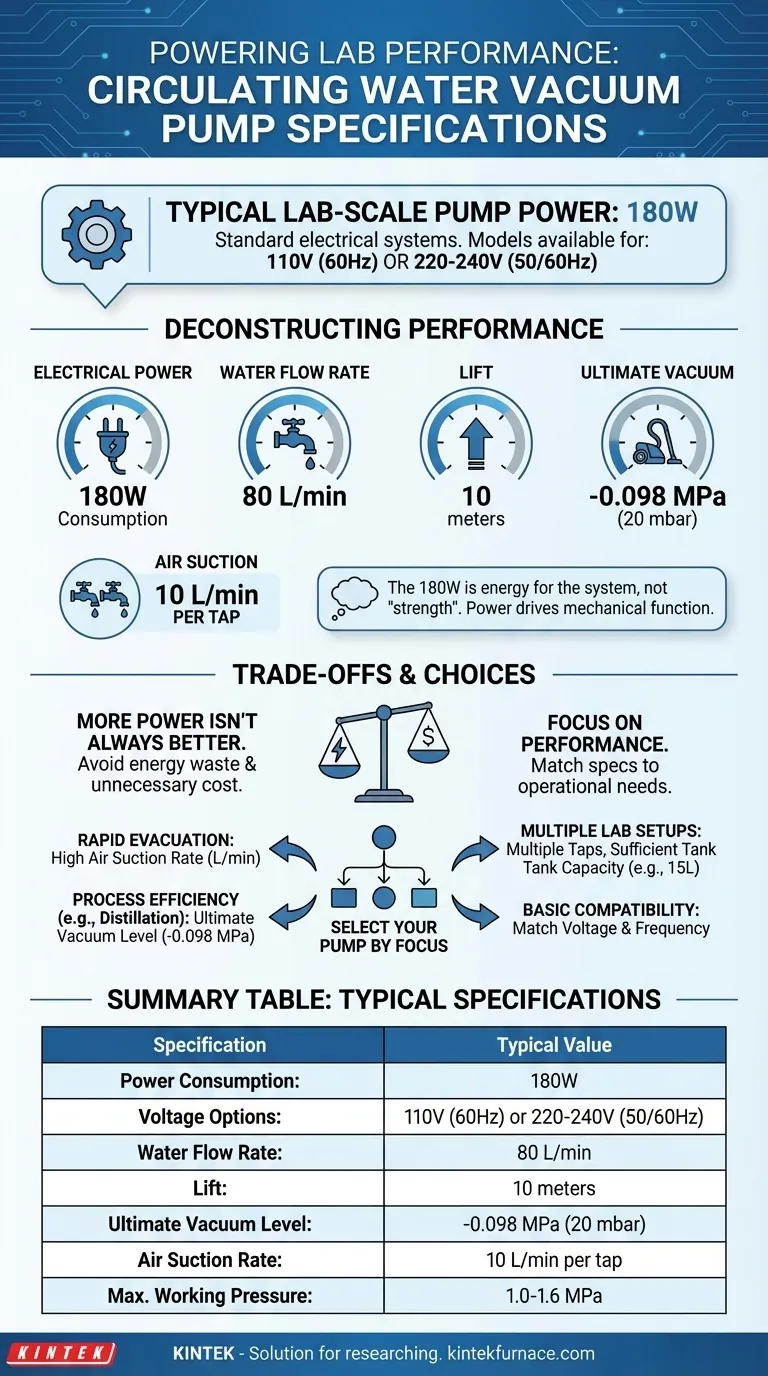

Deconstructing the Performance Specifications

A vacuum pump's power rating is not an isolated number. It is intrinsically linked to the work the pump is designed to do. Understanding the other key metrics provides a complete picture of its capabilities.

Electrical Power and Supply

A 180W rating indicates the electrical power the pump motor consumes during operation. It's crucial to match the pump's required voltage (110V or 220-240V) and frequency (50Hz or 60Hz) to your facility's electrical outlets to ensure safe and correct operation.

Pumping Performance (Water Circulation)

The electrical power drives the pump's primary mechanical function. A typical model specifies a water flow rate of 80 L/min and a lift of 10 meters. This means the pump can circulate 80 liters of water per minute and can push that water vertically up to 10 meters, overcoming system resistance.

Vacuum Capability

The core purpose of this device is to create a vacuum. A common ultimate vacuum level is -0.098 MPa (megapascals), which is equivalent to 2 KPa (kilopascals) or 20 mbar of absolute pressure. This specification defines the lowest pressure the pump can achieve.

Air Suction Rate

Linked to vacuum capability is the air suction amount, often around 10 L/min per tap. This metric tells you how quickly the pump can evacuate air from a connected apparatus, like a distillation or filtration setup. Many units feature two taps, allowing for simultaneous use.

How Power Translates to Performance

The 180W power rating is not a measure of the vacuum's "strength" but rather the energy required to run the entire system.

Power as a Function of Work

The motor's power is what's needed to drive the centrifugal pump mechanism. This work involves moving the circulating water (80 L/min), generating the negative pressure (-0.098 MPa), and overcoming internal friction and pressure losses.

Matching Motor to Application

A more demanding application, such as one requiring a higher water flow rate or a faster evacuation speed, would necessitate a pump with a more powerful motor and thus a higher wattage rating. The 180W specification is typical for common lab applications like evaporation, drying, and vacuum filtration.

Understanding the Trade-offs

Selecting a pump solely based on its power rating is a common mistake. You must consider how the specifications align with your operational needs and constraints.

More Power Isn't Always Better

Choosing a pump that is significantly more powerful than required for your process leads to wasted energy and unnecessary cost. The goal is to find a pump that efficiently meets your performance targets, not to simply maximize a single number.

Flow Rate vs. Air Suction

It's critical not to confuse the water circulation flow rate (e.g., 80 L/min) with the air suction rate (e.g., 10 L/min). The former relates to the pump's cooling and water-moving capacity, while the latter determines how fast you can evacuate your experimental setup.

Operational Pressure Limits

For advanced applications, be aware of the maximum working pressure, which is the sum of the inlet and pumping pressure. This is typically limited to 1.0 MPa or 1.6 MPa and represents a structural and operational safety limit for the pump casing and seals.

Making the Right Choice for Your Application

To select the correct pump, shift your focus from the power input to the performance output you need to achieve your goal.

- If your primary focus is rapid evacuation of a large volume: Prioritize a model with a high air suction rate (L/min) while ensuring the ultimate vacuum level meets your process requirements.

- If your primary focus is process efficiency (e.g., distillation): The ultimate vacuum level (-0.098 MPa) is the most critical factor, as it determines the boiling point of your solvent.

- If your primary focus is supporting multiple lab setups: Look for a pump with multiple suction taps and a sufficient water tank capacity (e.g., 15L) to handle the load without frequent refilling.

- If your primary focus is basic compatibility: Confirm that the pump’s voltage (110V or 220V) and frequency (50/60Hz) match your lab’s power infrastructure.

Choosing the right circulating water vacuum pump is about matching its complete performance profile to the specific demands of your work.

Summary Table:

| Specification | Typical Value |

|---|---|

| Power Consumption | 180W |

| Voltage Options | 110V (60Hz) or 220-240V (50/60Hz) |

| Water Flow Rate | 80 L/min |

| Lift | 10 meters |

| Ultimate Vacuum Level | -0.098 MPa (20 mbar) |

| Air Suction Rate | 10 L/min per tap |

| Maximum Working Pressure | 1.0-1.6 MPa |

Need a reliable vacuum pump tailored to your lab's unique needs? KINTEK leverages exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we can precisely meet your experimental requirements. Contact us today to discuss how our products can enhance your efficiency and performance!

Visual Guide

Related Products

- Ultra Vacuum Electrode Feedthrough Connector Flange Power Lead for High Precision Applications

- CF KF Flange Vacuum Electrode Feedthrough Lead Sealing Assembly for Vacuum Systems

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

People Also Ask

- Why is a laboratory reactor necessary for modified phenolic resin synthesis? Achieve Precision in Polymerization

- How does an evaporation and mixing unit assist in fuel ignition study? Enhance Research with Precise Vapor Control

- What is the purpose of a PTFE-lined autoclave in TiO2 synthesis? Unlock Precision Nano-material Growth

- How does the circulating water multifunctional vacuum pump create a vacuum? Discover Its Oil-Free Mechanism

- How does the geometric design of a sample basket affect measurement accuracy in thermogravimetric analysis?

- Why is a laboratory oven utilized during the pre-treatment stage of chicken bone waste pyrolysis?

- Why are alumina boats used for Bi2Se3 deposition? Ensure High-Purity Synthesis for Topological Insulators

- What are some key terms related to Laboratory Furnaces? Demystify Types Like Muffle and Tube Furnaces