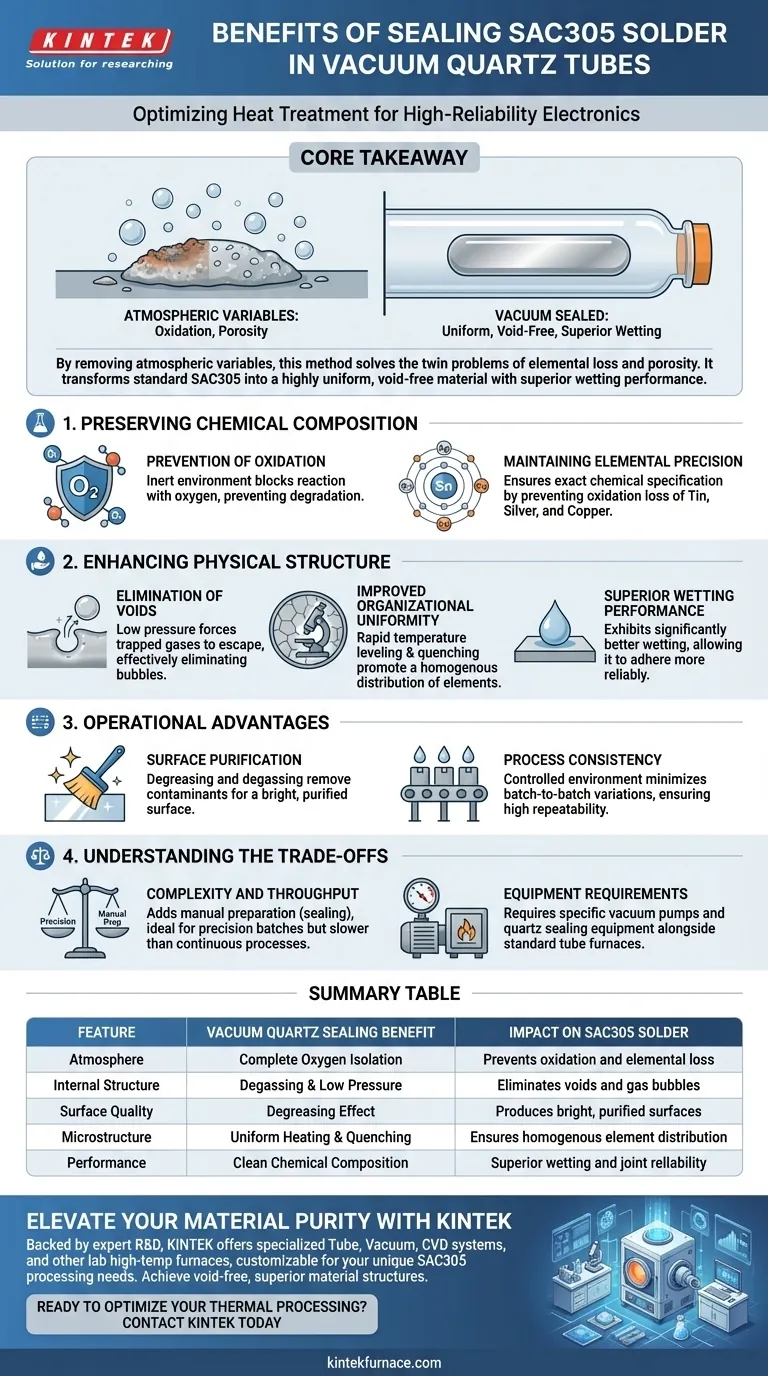

The primary benefit of sealing SAC305 lead-free solder in vacuum quartz tubes is the rigorous preservation of the alloy’s chemical and structural integrity during heat treatment. This isolation technique directly prevents the oxidation of metallic elements at high temperatures, ensuring the chemical composition remains precise, while the low-pressure environment actively eliminates internal gas bubbles.

Core Takeaway By removing atmospheric variables, this method solves the twin problems of elemental loss and porosity. It transforms standard SAC305 alloy into a highly uniform, void-free material with superior wetting performance, essential for high-reliability electronics.

Preserving Chemical Composition

Prevention of Oxidation

High-temperature processing usually exposes metals to oxygen, leading to material degradation. Sealing the solder in a vacuum quartz tube creates an inert environment that effectively blocks this reaction.

Maintaining Elemental Precision

SAC305 relies on a specific ratio of Tin, Silver, and Copper for its mechanical properties. By preventing the oxidation loss of these metallic elements, the vacuum sealing process ensures the final alloy matches its intended chemical specification exactly.

Enhancing Physical Structure

Elimination of Voids

The low-pressure environment created within the quartz tube serves a critical mechanical function. It forces trapped gases to escape, effectively eliminating bubbles that would otherwise form voids in the solder.

Improved Organizational Uniformity

When this vacuum sealing is combined with heating in a tube furnace and subsequent water quenching, the internal structure of the alloy changes. The rapid temperature leveling promotes a homogenous distribution of the elements, resulting in a more consistent microstructure.

Superior Wetting Performance

The removal of oxides and the homogenization of the alloy directly impact how the solder behaves in application. The treated solder exhibits significantly better wetting performance, allowing it to spread more easily and adhere more reliably to contact surfaces.

Operational Advantages

Surface Purification

Beyond internal structure, the vacuum environment acts as a cleaning agent. It has inherent degreasing and degassing effects, removing surface contaminants and phosphorus chips to produce a bright, purified surface.

Process Consistency

Because the environment inside the tube is controlled and isolated, the process offers high invariance and repeatability. This minimizes batch-to-batch variations, a common issue in open-atmosphere heat treatments.

Understanding the Trade-offs

Complexity and Throughput

While vacuum heat treatment is generally efficient, the specific step of sealing materials in quartz tubes adds a layer of manual preparation. This is ideal for precision batches but may represent a bottleneck compared to continuous, non-vacuum conveyor processes.

Equipment Requirements

Implementing this method requires access to specific vacuum pumps and quartz sealing equipment, alongside standard tube furnaces. The increased energy efficiency of the vacuum heating phase helps offset these costs, but the initial setup is more demanding than conventional methods.

Making the Right Choice for Your Goal

To determine if this vacuum quartz tube method is appropriate for your manufacturing process, consider your specific requirements for joint reliability and volume.

- If your primary focus is high-reliability interconnects: Implement this method to ensure void-free joints and precise alloy composition for critical applications like aerospace or automotive electronics.

- If your primary focus is improving wetting on difficult surfaces: Use this technique to leverage the degreasing and purification effects that occur during the vacuum cycle.

By controlling the atmosphere, you stop fighting against chemistry and start engineering a superior material structure.

Summary Table:

| Feature | Vacuum Quartz Sealing Benefit | Impact on SAC305 Solder |

|---|---|---|

| Atmosphere | Complete Oxygen Isolation | Prevents oxidation and elemental loss |

| Internal Structure | Degassing & Low Pressure | Eliminates voids and gas bubbles |

| Surface Quality | Degreasing Effect | Produces bright, purified surfaces |

| Microstructure | Uniform Heating & Quenching | Ensures homogenous element distribution |

| Performance | Clean Chemical Composition | Superior wetting and joint reliability |

Elevate Your Material Purity with KINTEK

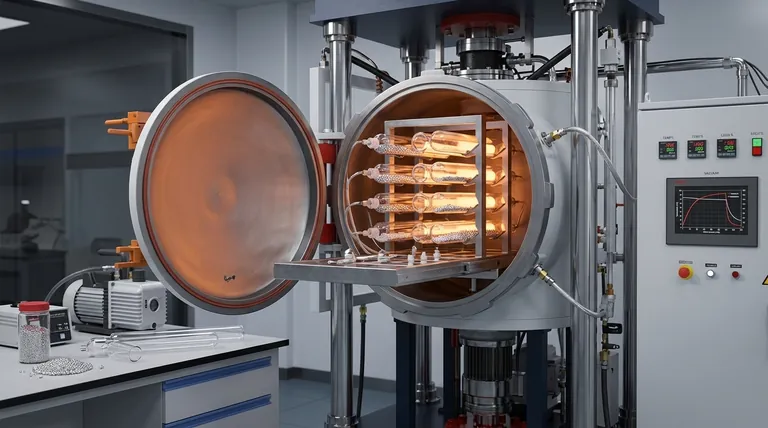

Precise heat treatment is the backbone of high-reliability electronics. Backed by expert R&D and manufacturing, KINTEK offers specialized Tube, Vacuum, CVD systems, and other lab high-temp furnaces, all customizable for your unique SAC305 processing needs. Whether you require rigorous atmospheric control or high-uniformity heating, our systems are designed to help you achieve void-free, superior material structures.

Ready to optimize your thermal processing? Contact KINTEK today to consult with our experts!

Visual Guide

References

- Chao-hong Wang, Yue-Han Li. Liquid-State Interfacial Reactions of Lead-Free Solders with FeCoNiCr and FeCoNiMn Medium-Entropy Alloys at 250 °C. DOI: 10.3390/ma18102379

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Vacuum Heat Treat Sintering and Brazing Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

People Also Ask

- Why is a sealing lid necessary for the clay-graphite crucible? Key to Successful Fe3O4/C Composite Synthesis

- What function does a PTFE liner serve in NiWO4 synthesis? Ensure Purity & Prevent Corrosion in Hydrothermal Reactors

- What critical functions do high-purity graphite molds perform? The Engine of SPS for High-Entropy Ceramics

- Why is rhenium selected as a material for sample capsules? Key Benefits for High-Temperature Experimental Success

- How does the use of a 100-mesh sieve contribute to the performance consistency of magnetic chitosan carbon?

- How does the density of alumina ceramics compare to steel? Uncover Lighter, High-Performance Material Solutions

- Why are vacuum-sealed quartz tubes required for SnSe melting? Ensure Purity & Stoichiometry

- What are the advantages of using a water circulating vacuum pump? Boost Lab Efficiency with Corrosion Resistance