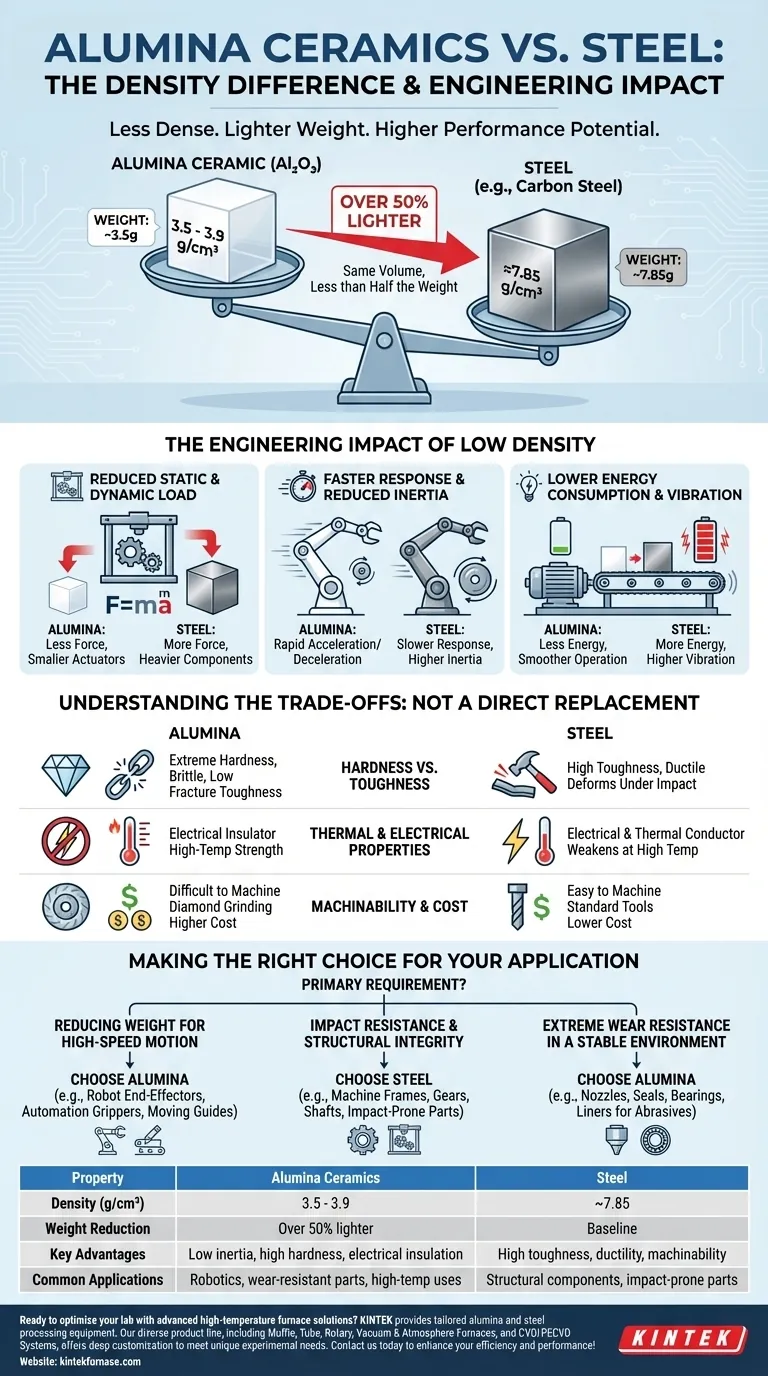

In simple terms, alumina ceramic is significantly less dense than steel. With a typical density around 3.5 to 3.9 g/cm³, an alumina component will weigh less than half as much as an identically sized component made from steel, which has a density of approximately 7.85 g/cm³. This substantial weight reduction is a primary reason for choosing alumina in many advanced engineering applications.

The core consideration is not just that alumina is lighter, but how this lower density fundamentally changes a system's performance. Choosing between alumina and steel requires balancing alumina's advantages in weight and hardness against steel's superior toughness and ductility.

The Engineering Impact of Low Density

The difference in density is more than a simple number; it has direct consequences for machine design, energy consumption, and operational efficiency. Understanding this is key to proper material selection.

Defining the Density Difference

Density is a measure of mass per unit of volume. A material with low density provides the same physical volume for significantly less weight.

For a direct comparison, a one-cubic-centimeter cube of steel weighs around 7.85 grams. An identical cube of alumina weighs only about 3.5 grams. This means for any given part, switching from steel to alumina can reduce its mass by over 50%.

Why Lower Density Reduces Equipment Load

This weight reduction impacts equipment in two critical ways: static and dynamic load.

Static load is the constant force exerted by the component's weight on its supporting structure. Lighter alumina parts reduce this load, allowing for less massive frames, bearings, and actuators, which can decrease the cost and complexity of the entire assembly.

Dynamic load relates to the forces required to start, stop, or change the direction of a component. Because force equals mass times acceleration (F=ma), a part with less mass requires proportionally less force to achieve the same acceleration.

Key Advantages of Alumina's Low Mass

In applications involving motion, the benefits of low density compound quickly. Lower mass is the gateway to higher performance.

Reduced Inertia and Faster Response

Inertia is an object's resistance to changes in its state of motion. Lighter components have lower inertia, allowing them to accelerate and decelerate much more quickly.

This is critical for robotics, high-speed automation, and rotating machinery where rapid, precise movements are essential for performance and throughput.

Lower Energy Consumption

Moving a lighter component requires less energy. Over millions of cycles in an automated system, the energy savings from using alumina parts can be substantial, leading to lower operational costs.

Minimized Vibration and Wear

In high-speed systems, the momentum of heavy components can cause significant vibration. Lighter alumina parts generate less momentum and vibration, leading to smoother operation and reduced wear on associated components like bearings and drives.

Understanding the Trade-offs: Alumina is Not a Direct Replacement for Steel

While its low density is a major advantage, alumina has vastly different properties from steel. A successful design depends on understanding these critical trade-offs.

Hardness vs. Toughness

Alumina is exceptionally hard and wear-resistant, far surpassing even hardened steels. It is excellent for abrasive environments.

However, it is also very brittle. Steel is tough and ductile, meaning it will bend or deform under impact. Alumina has low fracture toughness and can shatter from a sudden shock that would merely dent a steel part.

Thermal and Electrical Properties

Alumina is an excellent electrical insulator and maintains its strength at very high temperatures where steel would weaken. Steel, by contrast, is a thermal and electrical conductor.

Machinability and Cost

Steel is relatively easy to machine into complex shapes. Alumina is extremely hard, so it must be diamond-ground to its final dimensions after firing. This process is slower and more expensive, increasing the final part cost, especially for complex geometries.

Making the Right Choice for Your Application

The decision to use alumina or steel must be driven by the single most important requirement of the component.

- If your primary focus is reducing weight for high-speed motion: Choose alumina for components like robot end-effectors, automation grippers, and moving guides where low inertia is paramount.

- If your primary focus is impact resistance and structural integrity: Choose steel for machine frames, gears, shafts, and any part subjected to sudden or high loads.

- If your primary focus is extreme wear resistance in a stable, non-impact environment: Choose alumina for components like nozzles, seals, bearings, and liners that handle abrasive materials.

Ultimately, effective material selection comes from matching the unique strengths of a material to the specific demands of your engineering problem.

Summary Table:

| Property | Alumina Ceramics | Steel |

|---|---|---|

| Density (g/cm³) | 3.5 - 3.9 | ~7.85 |

| Weight Reduction | Over 50% lighter | Baseline |

| Key Advantages | Low inertia, high hardness, electrical insulation | High toughness, ductility, machinability |

| Common Applications | Robotics, wear-resistant parts, high-temperature uses | Structural components, impact-prone parts |

Ready to optimize your lab with advanced high-temperature furnace solutions? Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with tailored alumina and steel processing equipment. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by strong deep customization capabilities to precisely meet your unique experimental needs. Contact us today to discuss how we can enhance your efficiency and performance!

Visual Guide

Related Products

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- Spark Plasma Sintering SPS Furnace

People Also Ask

- What types of production processes benefit from the thermal uniformity of tube furnaces? Enhance Precision in Material Processing

- What is flash vacuum pyrolysis and how is a tube furnace utilized in this process? Unlock High-Temp Chemical Reactions

- What industries benefit from the use of tube furnaces? Unlock Precision in Semiconductor and Battery Tech

- How do roller kilns and tube furnaces differ in their use of Alumina ceramic tubes? Compare Transport vs. Containment

- What other types of reactions can tube furnaces be used for? Explore Versatile Thermal Processes for Your Lab