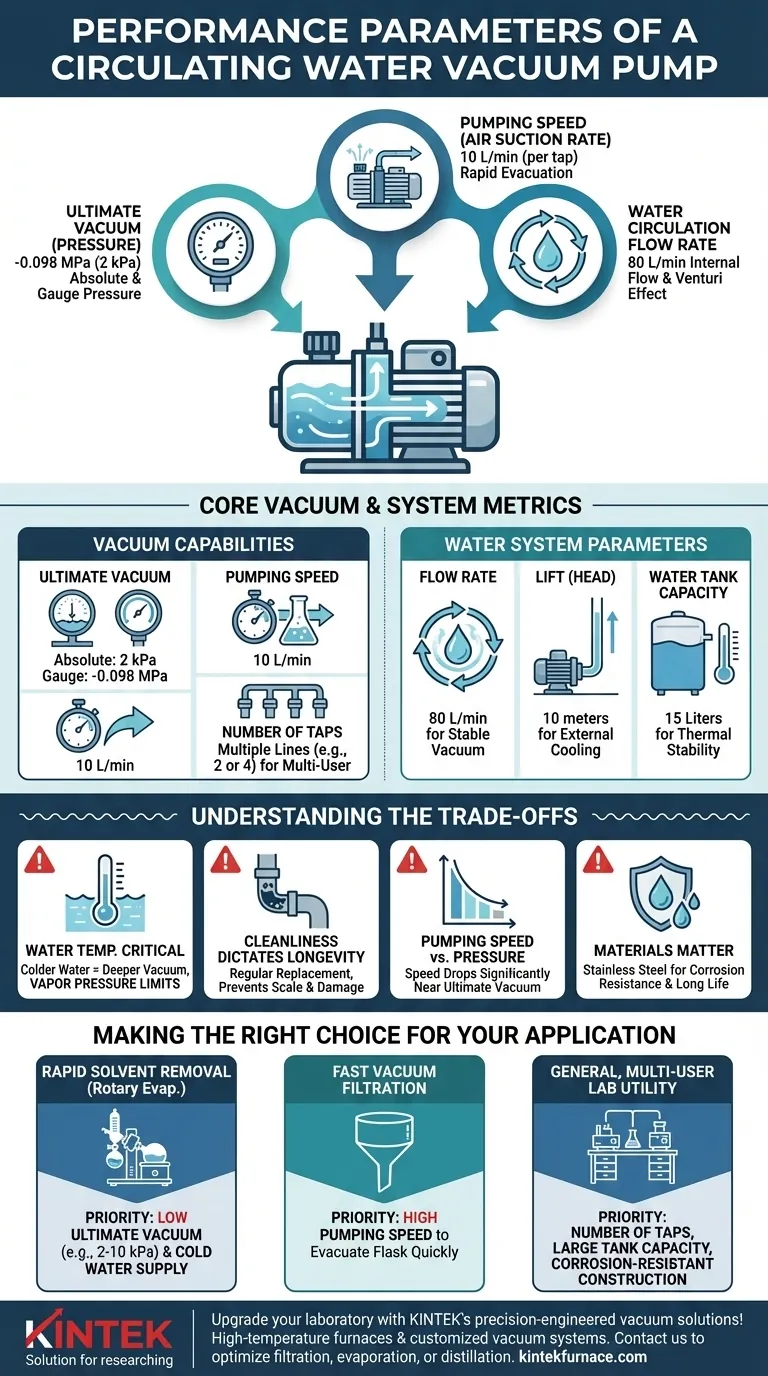

The core performance parameters of a circulating water vacuum pump are its ultimate vacuum level, air suction rate (pumping speed), and water circulation flow rate. For a typical lab-scale pump, these values might be an ultimate vacuum of -0.098 MPa (2 kPa), a single-tap suction rate of 10 L/min, and a water flow rate of 80 L/min. These figures define the pump's ability to create and maintain a vacuum for applications like filtration, evaporation, and distillation.

A pump's datasheet provides numbers, but true performance is a balance between three distinct factors: the depth of the vacuum (ultimate pressure), the speed at which it evacuates a chamber (pumping speed), and the efficiency of its water circulation system, which directly impacts both.

Core Vacuum Performance Metrics

Understanding a pump's vacuum capabilities requires looking beyond a single number. The key metrics describe both how deep the vacuum can be and how quickly it can be achieved.

Ultimate Vacuum (Pressure)

This is the lowest pressure the pump can possibly achieve under ideal conditions. It is the most common headline specification.

It's often expressed in two ways:

- Absolute Pressure: Such as 2 kPa. This measures the pressure remaining in the system. Lower numbers are better, indicating a deeper vacuum.

- Gauge Pressure: Such as -0.098 MPa. This measures the pressure below atmospheric pressure. Numbers closer to -0.101 MPa (absolute zero pressure) are better.

Pumping Speed (Air Suction Rate)

This parameter defines how quickly the pump can remove gas from a chamber. It is typically measured in liters per minute (L/min).

A specification like "single tap air suction amount of 10" indicates that each vacuum port can evacuate gas at a rate of 10 L/min. This determines how long it will take to pull a vacuum on your apparatus.

Number of Taps

This is a practical performance feature, indicating how many independent vacuum lines can be run simultaneously. A pump with two or four taps can serve multiple users or experiments at once, maximizing utility in a shared lab space.

Water Circulation & System Parameters

The "circulating water" in the pump's name is its working fluid. The performance of this water system is fundamental to the pump's ability to generate a vacuum.

Flow Rate

This specifies the volume of water the pump circulates internally, such as 80 L/min. This internal flow creates the Venturi effect that generates the vacuum. A robust flow is essential for stable and consistent vacuum performance.

Lift (Head)

Lift, often measured in meters (e.g., 10 meters), describes the pump's ability to push water vertically. While most of the water circulates internally, this parameter is critical if you intend to use the pump to supply cooling water to an external device, like a condenser on a rotary evaporator.

Water Tank Capacity

A larger water tank (e.g., 15 liters) provides greater thermal stability. As the pump works, the water heats up. A larger volume of water heats more slowly, which helps maintain a deeper, more consistent vacuum over a longer operational period.

Understanding the Trade-offs

Selecting a pump requires understanding the compromises and operational realities that affect its real-world performance.

Water Temperature is Critical

The ultimate vacuum of a water jet pump is physically limited by the vapor pressure of the water used as the working fluid. Colder water has a lower vapor pressure, which allows the pump to achieve a deeper vacuum. As the circulating water heats up during operation, the achievable vacuum level will decrease.

Cleanliness Dictates Longevity

The performance specifications are only valid with clean water. Dissolved minerals can form scale and clog the jets, reducing performance. If you are pumping corrosive vapors, they will dissolve in the water. Regularly replacing the water is the most critical maintenance step to ensure consistent vacuum and prevent damage.

Pumping Speed vs. Pressure

A pump's stated pumping speed (e.g., 10 L/min) is typically its maximum rate at or near atmospheric pressure. As the system approaches its ultimate vacuum, the effective pumping speed drops significantly. It takes much longer to remove the last few percent of gas.

Materials Matter for Application

Pumps constructed from stainless steel or other anti-corrosion materials are a performance feature, not just a physical one. They ensure the pump can withstand harsh chemical vapors without degrading, providing a longer service life and preventing contamination of the vacuum system.

Making the Right Choice for Your Application

Choose a pump by matching its key parameters to your primary goal.

- If your primary focus is rapid solvent removal (rotary evaporation): Prioritize a low ultimate vacuum (e.g., 2-10 kPa) and ensure you can supply it with cold water to handle solvents effectively.

- If your primary focus is fast vacuum filtration: Prioritize a high pumping speed (air suction rate) to evacuate the filter flask quickly.

- If your primary focus is general, multi-user lab utility: Prioritize the number of taps, a large water tank capacity for stability, and corrosion-resistant construction for durability.

Ultimately, understanding these interconnected parameters empowers you to select a tool that is not just adequate, but perfectly suited to your scientific work.

Summary Table:

| Parameter | Description | Typical Value |

|---|---|---|

| Ultimate Vacuum | Lowest pressure achievable, indicating vacuum depth | 2 kPa or -0.098 MPa |

| Pumping Speed | Rate of gas removal, affecting evacuation time | 10 L/min per tap |

| Water Flow Rate | Internal circulation volume for stable vacuum generation | 80 L/min |

| Number of Taps | Independent vacuum lines for multi-user setups | Varies (e.g., 2 or 4) |

| Water Tank Capacity | Volume for thermal stability during operation | 15 liters |

| Lift (Head) | Ability to push water vertically for external cooling | 10 meters |

Upgrade your laboratory with KINTEK's precision-engineered vacuum solutions! Leveraging exceptional R&D and in-house manufacturing, we provide advanced high-temperature furnaces and vacuum systems tailored for diverse labs. Our product line includes Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, enhanced by deep customization to meet your unique experimental needs. Whether you're optimizing for filtration, evaporation, or distillation, our expertise ensures reliable performance and efficiency. Contact us today to discuss how we can enhance your lab's capabilities!

Visual Guide

Related Products

- Ultra Vacuum Electrode Feedthrough Connector Flange Power Lead for High Precision Applications

- CF KF Flange Vacuum Electrode Feedthrough Lead Sealing Assembly for Vacuum Systems

- Laboratory Vacuum Tilt Rotary Tube Furnace Rotating Tube Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

People Also Ask

- What is the function of high-purity graphite crucibles in Al-Cu-Mn master alloy prep? Ensure Chemical Purity

- What is the primary function of graphitized quartz glass tubes in the synthesis of Bi2Se3-Nd2Se3 alloys?

- What is the function of high-alumina crucibles in LLZO calcination? Optimize Battery Material Purity

- What is the function of high-purity alumina crucibles in NRBBO:Eu2+ sintering? Ensure Pure Phosphor Synthesis

- What factors influence the lifespan of alumina ceramic furnace tubes? Maximize Durability and Performance

- What maintenance is required for a water circulating vacuum pump? Ensure Peak Performance and Longevity

- What is the technical value of using a narrowband infrared pyrometer? Expert Precision for High-Temp Measurement

- What is the function of high-vacuum encapsulated quartz tubes for Ce2(Fe, Co)17? Ensure Phase Purity and Stability