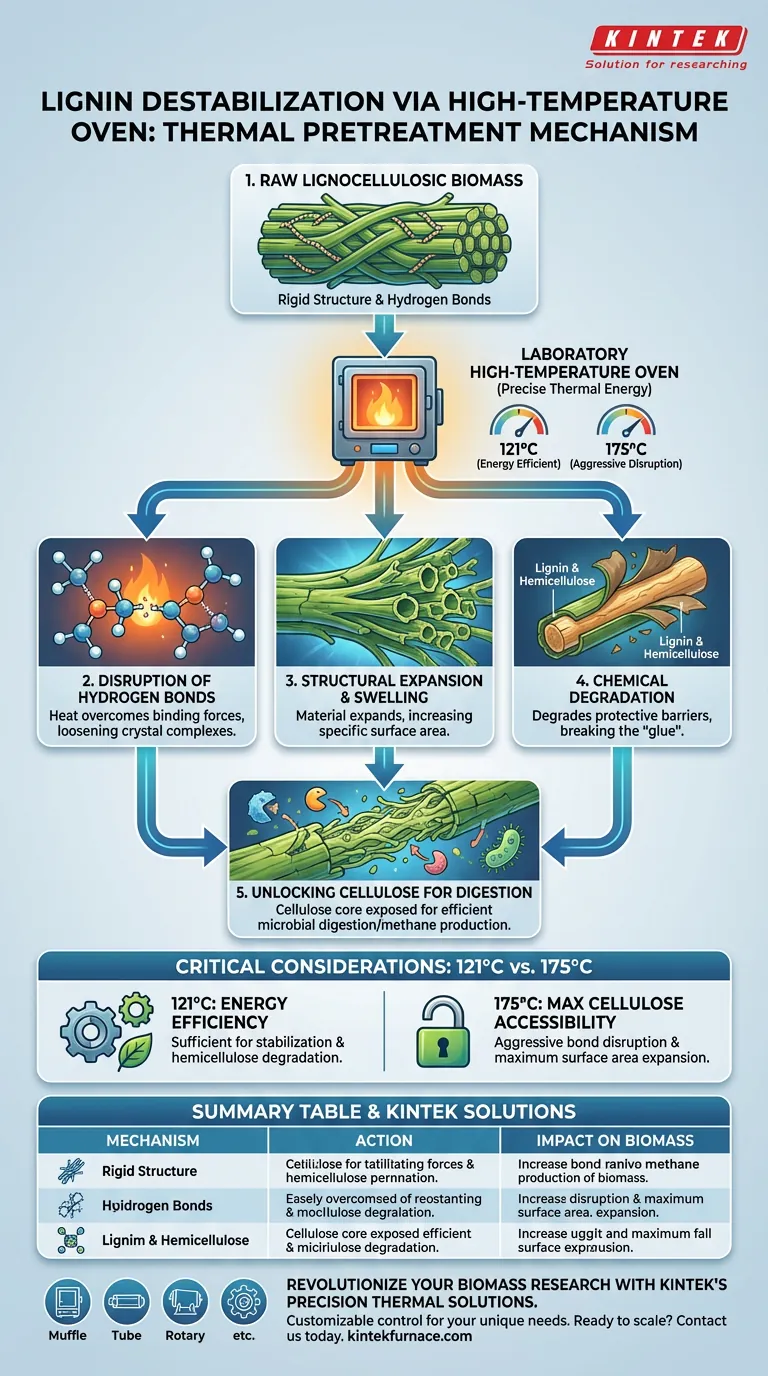

A laboratory high-temperature oven facilitates lignin destabilization by applying precise thermal energy, typically at temperatures like 121°C or 175°C, to physically disrupt the rigid structure of biomass. This controlled heating breaks the hydrogen bonds within lignocellulosic crystal complexes, causing the material to expand and effectively degrading the lignin and hemicellulose barriers.

The core function of thermal pretreatment is not just heating, but structural expansion. By severing hydrogen bonds, the oven increases the biomass's specific surface area, stripping away lignin to make the underlying cellulose accessible for microbial digestion.

The Mechanism of Destabilization

Disruption of Hydrogen Bonds

Lignocellulosic biomass derives its rigidity from complex networks of hydrogen bonds holding crystal complexes together.

The oven introduces high thermal energy that directly targets these bonds. As the temperature rises to levels such as 121°C or 175°C, the energy overcomes the binding forces, causing the rigid crystal structure to loosen and fracture.

Expansion of Biomass

Once the hydrogen bonds are disrupted, the physical structure of the biomass undergoes a transformation.

The thermal energy causes the material to expand. This swelling action forces the tightly packed fibers apart, creating a more porous structure that is less resistant to chemical or biological attack.

Increasing Accessible Surface Area

The destabilization of lignin is directly tied to the available surface area of the material.

By expanding the biomass and degrading the outer layers, the oven significantly increases the accessible specific surface area. This is the critical factor that allows enzymes or microbes to penetrate the material in subsequent processing steps.

Chemical Transformation and Accessibility

Degrading Lignin and Hemicellulose

Heat treatment does more than physically expand the material; it chemically alters the protective layers.

The process effectively degrades lignin and hemicellulose, the components that typically shield cellulose fibers. This degradation breaks down the "glue" that holds the plant cell walls together, rendering the structure unstable.

Unlocking Cellulose for Digestion

The ultimate goal of this thermal destabilization is to expose the cellulose core.

With the lignin degraded and the surface area expanded, the remaining cellulose becomes highly accessible. This prepares the biomass for efficient microbial digestion or methane production, processes that would be inefficient or impossible without this thermal intervention.

Critical Considerations and Trade-offs

The Necessity of Precise Control

While heat is the mechanism, precision is the key to success.

A laboratory oven provides a controlled thermal environment to ensure the temperature is high enough to disrupt bonds but stable enough to prevent unwanted combustion or charring.

Balancing Temperature and Degradation

There is a functional difference between 121°C and 175°C.

Higher temperatures generally accelerate the degradation of lignin and the expansion of surface area. However, the specific temperature must be chosen based on the desired balance between energy consumption and the extent of lignin breakdown required for the specific type of biomass.

Making the Right Choice for Your Goal

When configuring a high-temperature oven for biomass pretreatment, align your parameters with your downstream objectives.

- If your primary focus is maximum cellulose accessibility: Target higher temperature ranges (e.g., 175°C) to ensure aggressive disruption of hydrogen bonds and maximum expansion of specific surface area.

- If your primary focus is energy efficiency: utilize the lower effective range (e.g., 121°C), which is sufficient to degrade hemicellulose and loosen lignin without the energy cost of higher thermal plateaus.

Thermal pretreatment is the definitive step that transforms recalcitrant raw biomass into a viable feedstock for bio-production.

Summary Table:

| Mechanism | Action | Impact on Biomass |

|---|---|---|

| Thermal Energy | Disruption of hydrogen bonds | Loosens rigid crystal complexes |

| Structural Expansion | Physical swelling of fibers | Increases porous structure and surface area |

| Chemical Degradation | Breakdown of lignin/hemicellulose | Removes the protective 'glue' around cellulose |

| Accessibility | Exposing cellulose core | Maximizes efficiency for microbial digestion |

Revolutionize Your Biomass Research with KINTEK

Unlock the full potential of your lignocellulosic research with KINTEK’s precision thermal solutions. Backed by expert R&D and world-class manufacturing, we provide high-performance Muffle, Tube, Rotary, Vacuum, and CVD systems tailored for critical pretreatment processes. Whether you need aggressive lignin degradation at 175°C or energy-efficient stabilization at 121°C, our lab high-temp furnaces offer the customizable control required for your unique material needs.

Ready to scale your bio-production? Contact us today to discuss how our specialized heating equipment can enhance your lab's efficiency and experimental accuracy.

Visual Guide

References

- Đurđica Kovačić, Mladen Jurišić. Influence of Thermal Pretreatment on Lignin Destabilization in Harvest Residues: An Ensemble Machine Learning Approach. DOI: 10.3390/agriengineering6010011

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

People Also Ask

- Why are high-purity alumina boats utilized as precursor containers in MoS2 synthesis? Ensure High-Quality 2D Materials

- What are the roles of rotameters and digital flow controllers in pneumatic systems? Enhance Precision and Testing

- Why is a two-stage vacuum unit used in magnesium distillation? For Faster, More Efficient Pumping

- What are the benefits of using high-purity alumina or platinum crucibles? Enhance Purity in Specialized Glass Melting

- Why use sealed quartz tubes & vacuum for Mg-Zn/Mg-Cd alloy prep? Ensure Compositional Purity

- How does an Aluminum Oxide Crucible ensure MXene purity? Key Role of LSS Etching Protection

- Why is radiation correction necessary for K-type thermocouple readings? Ensure Accurate High-Temp Combustion Data

- What is the purpose of a water circulating vacuum pump? Achieve Clean, Efficient Vacuum for Lab Processes