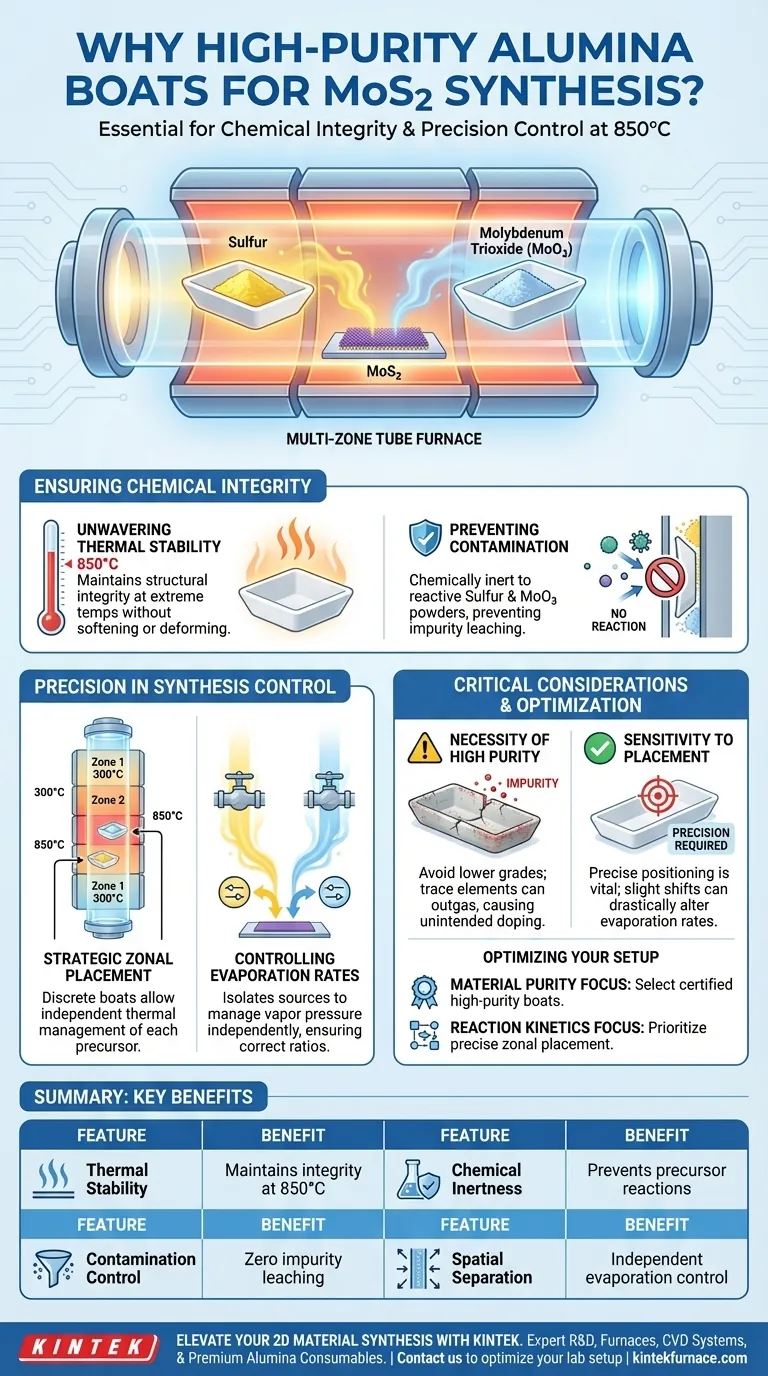

High-purity alumina boats are essential tools in MoS2 synthesis because they provide a chemically inert environment capable of withstanding extreme thermal conditions. Specifically, they facilitate the reaction by holding precursors like sulfur and molybdenum trioxide at operating temperatures of 850°C without introducing contaminants or reacting with the source materials.

The utility of high-purity alumina lies in its dual ability to resist high-temperature chemical corrosion and enable precise control over precursor evaporation rates within a multi-zone tube furnace.

Ensuring Chemical Integrity

Unwavering Thermal Stability

MoS2 synthesis requires rigorous thermal conditions, often reaching operating temperatures of 850°C.

High-purity alumina boats are selected because they maintain their structural integrity at these specific heat levels. They do not soften, deform, or degrade, ensuring the physical containment of the precursors throughout the experiment.

Preventing Precursor Contamination

The most critical function of these boats is their chemical inertness.

At elevated temperatures, reactive powders like Sulfur (S) and Molybdenum Trioxide (MoO3) can easily interact with lesser container materials. High-purity alumina does not react with these powders, preventing impurities from leaching into the synthesis environment and compromising the quality of the MoS2 layers.

Precision in Synthesis Control

Strategic Zonal Placement

The use of discrete boats allows for strategic placement within a tube furnace.

By positioning the alumina boats in specific temperature zones, researchers can manipulate the thermal environment for each precursor independently. This spatial separation is vital for managing the reaction kinetics.

Controlling Evaporation Rates

Successful synthesis depends on managing the vapor pressure of the source materials.

Because the boats isolate the Sulfur and Molybdenum sources, their evaporation rates can be controlled independently. This ensures that the correct ratio of vapors reaches the substrate, promoting the growth of high-quality films.

Critical Considerations and Pitfalls

The Necessity of "High Purity"

It is important not to compromise on the grade of alumina used. Lower-purity boats may contain trace elements that could outgas or react at 850°C, negating the benefits of the container and introducing unintended doping effects.

Sensitivity to Placement

While the boats allow for independent control, this introduces a variable that requires precision. Incorrectly placing a boat by even a small margin within the temperature gradient can drastically alter the evaporation rate, leading to non-stoichiometric growth or failed synthesis.

Optimizing Your Experimental Setup

To ensure successful MoS2 growth, align your container selection with your specific experimental needs:

- If your primary focus is Material Purity: Ensure you select certified high-purity alumina boats to eliminate any risk of reaction with Sulfur or MoO3 at 850°C.

- If your primary focus is Reaction Kinetics: Prioritize the precise placement of these boats within the furnace's temperature zones to independently tune the evaporation rates of your precursors.

By leveraging the thermal stability and inert nature of high-purity alumina, you create a controlled, contaminant-free environment essential for high-quality 2D material synthesis.

Summary Table:

| Feature | Benefit for MoS2 Synthesis |

|---|---|

| Thermal Stability | Maintains structural integrity at 850°C without deformation. |

| Chemical Inertness | Prevents reactions with Sulfur and MoO3 precursors. |

| Contamination Control | Ensures zero leaching of impurities for high-purity 2D layers. |

| Spatial Separation | Allows independent control of evaporation rates in multi-zone furnaces. |

Elevate Your 2D Material Synthesis with KINTEK

Precision in MoS2 synthesis begins with the highest quality laboratory equipment. At KINTEK, we understand that even minor impurities can compromise your research. Backed by expert R&D and manufacturing, we offer a comprehensive range of Muffle, Tube, Rotary, Vacuum, and CVD systems, along with premium high-purity alumina consumables tailored for your unique experimental needs.

Don't let subpar materials derail your results. Partner with KINTEK for customizable, high-temperature lab solutions designed for excellence.

Contact us today to optimize your lab setup

Visual Guide

References

- Feng Liao, Zewen Zuo. Optimizing the Morphology and Optical Properties of MoS2 Using Different Substrate Placement: Numerical Simulation and Experimental Verification. DOI: 10.3390/cryst15010059

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Magnesium Extraction and Purification Condensing Tube Furnace

- Split Chamber CVD Tube Furnace with Vacuum Station CVD Machine

- RF PECVD System Radio Frequency Plasma Enhanced Chemical Vapor Deposition

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

People Also Ask

- How does an electromechanical vibrator assist in fuel feeding? Enhance Coal and Biomass Combustion Stability

- What is Alumina and how is it derived? Discover Its Role in Advanced Materials and Production

- What role do contact thermocouples play during the high-temperature annealing experiments of oriented silicon steel?

- What customization options are available for laboratory furnaces? Tailor Your Furnace for Precise Thermal Control

- What is the significance of using ceramic or quartz sample boats for solid fuels? Ensure Precise Thermal Analysis

- What is the role of quartz capillaries in the vacuum sealing process of sulfur? Enhance Purity and In-Situ Analysis

- How does a precision Mass Flow Controller (MFC) regulate argon carrier gas to affect the growth of WS2 nanosheets?

- What function does a laboratory blast drying oven perform? Optimize Pretreatment for Magnetic Particles