At its core, a water circulating vacuum pump is a device that uses a jet of water to create a moderate vacuum. It is specifically designed to provide the negative pressure conditions required for common laboratory and industrial processes like evaporation, distillation, crystallization, drying, and reduced pressure filtration.

Unlike oil-sealed pumps that risk sample contamination, a water circulating vacuum pump offers a clean, reliable vacuum by using recycled water as its working fluid. This makes it an ideal, resource-conscious choice for many standard laboratory procedures.

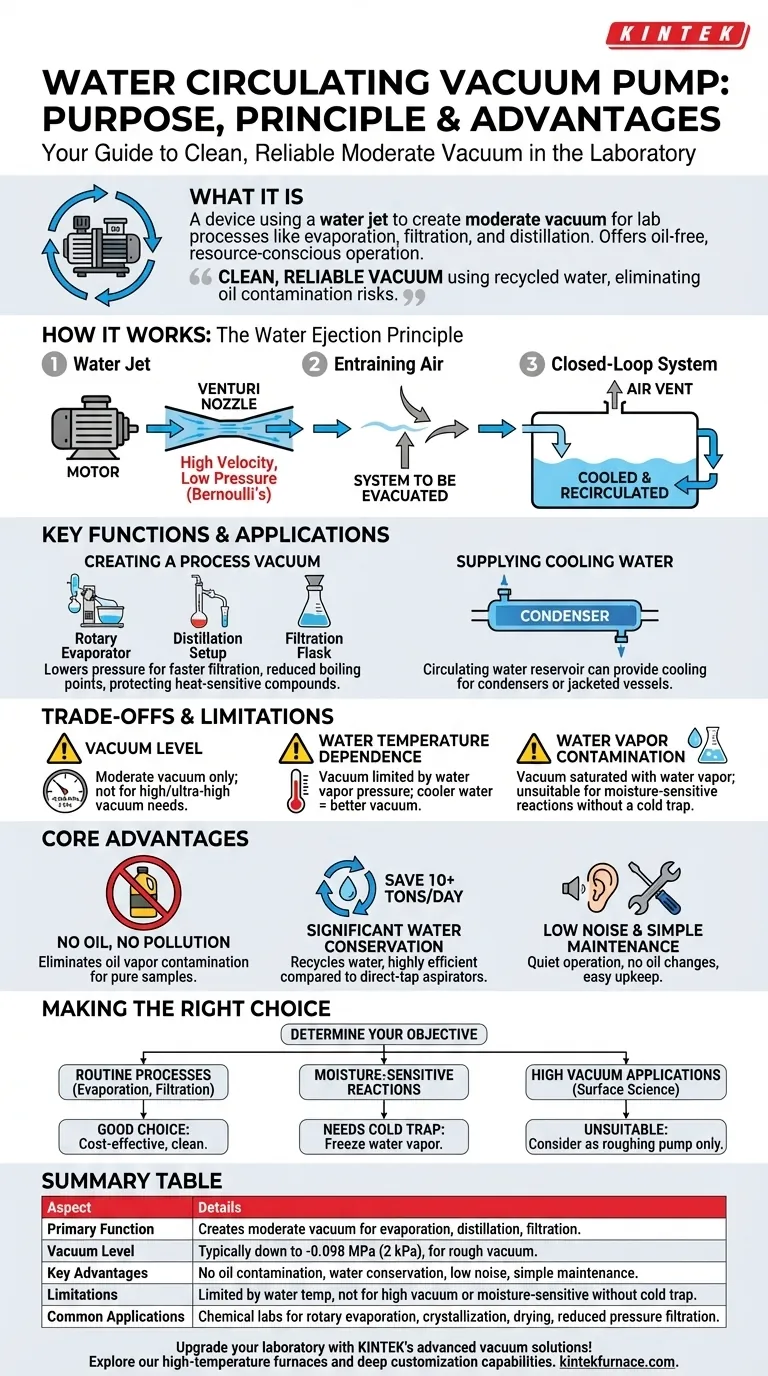

How It Works: The Principle of Water Ejection

A water circulating vacuum pump operates on a simple yet effective fluid dynamics principle.

The Role of the Water Jet

The pump uses a motor to force water through a jet, or venturi. As the water passes through a narrow constriction, its velocity increases dramatically, causing a sharp drop in pressure according to Bernoulli's principle.

Entraining Air

This low-pressure zone is connected to the vessel or system you need to evacuate. The higher-pressure air from your system is naturally drawn into the low-pressure water stream and becomes entrained in the flow.

The Closed-Loop System

The mixture of water and entrained air then flows into a wider area where it slows down, and the pressure increases. The air separates from the water and is vented to the atmosphere. Critically, the water collects in a built-in tank to be cooled and recirculated, forming a closed loop.

Key Functions and Applications

This pump's design makes it a versatile tool, particularly in a chemical laboratory setting.

Creating a Process Vacuum

The primary function is to lower the pressure within a sealed system. This is essential for speeding up filtration or for lowering the boiling point of solvents during distillation or rotary evaporation, protecting heat-sensitive compounds.

Supplying Cooling Water

As a secondary benefit, the pump contains a reservoir of circulating water. This can often be tapped to provide circulating cooling water for a condenser or a jacketed reaction vessel, adding a valuable dual-purpose capability.

Understanding the Trade-offs and Limitations

While highly useful, this type of pump is not the right tool for every vacuum application. Its effectiveness is governed by specific physical limitations.

Vacuum Level

A water circulating pump provides a moderate or "rough" vacuum, typically down to about -0.098 MPa (2 kPa). While sufficient for many solvent-based applications, it cannot achieve the high or ultra-high vacuum required for processes like mass spectrometry or surface science.

Dependence on Water Temperature

The ultimate vacuum this pump can achieve is limited by the vapor pressure of the water itself. Warmer water has a higher vapor pressure, which leads to a poorer vacuum. For best performance, the water in the reservoir must be kept cool.

Water Vapor Contamination

Because the working fluid is water, the vacuum created will be saturated with water vapor. This makes it unsuitable for highly moisture-sensitive reactions unless a cold trap is used in-line to freeze the water vapor before it reaches the system.

The Core Advantages of a Water-Based System

The choice to use a water circulating pump is often driven by its distinct advantages over oil-sealed alternatives.

No Oil, No Pollution

The most significant benefit is the elimination of oil vapor contamination. With only water as the working medium, there is no risk of oil back-streaming into your sample, ensuring process purity.

Significant Water Conservation

Compared to vacuum aspirators that connect directly to a tap and dump water down the drain, a circulating pump is incredibly efficient. By recycling its water, it can save over 10 tons of water in a single workday under the same conditions. This is a critical advantage in areas with water restrictions or high utility costs.

Low Noise and Simple Maintenance

These pumps are generally characterized by low noise and operational simplicity. There are no messy oil changes, and upkeep primarily involves keeping the water in the tank clean and cool.

Making the Right Choice for Your Goal

To determine if this pump is correct for your needs, consider your primary objective.

- If your primary focus is routine chemical processes like rotary evaporation or filtration: A water circulating vacuum pump is an excellent, cost-effective, and clean choice.

- If your primary focus is running highly moisture-sensitive reactions: You must account for the inherent water vapor by using a cold trap in series with the pump.

- If your primary focus is achieving high vacuum for surface science or deposition: This type of pump is unsuitable for that purpose and should only be considered as a preliminary roughing pump for a more advanced system.

Understanding these capabilities ensures you select a tool that is not only effective but also sustainable for your laboratory's needs.

Summary Table:

| Aspect | Details |

|---|---|

| Primary Function | Creates moderate vacuum for processes like evaporation, distillation, and filtration |

| Vacuum Level | Typically down to -0.098 MPa (2 kPa), suitable for rough vacuum applications |

| Key Advantages | No oil contamination, water conservation, low noise, simple maintenance |

| Limitations | Limited by water temperature, not for high vacuum or moisture-sensitive setups without a cold trap |

| Common Applications | Chemical labs for rotary evaporation, crystallization, drying, and reduced pressure filtration |

Upgrade your laboratory with KINTEK's advanced vacuum solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with reliable high-temperature furnace systems like Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we precisely meet your unique experimental needs for enhanced efficiency and purity. Contact us today to discuss how our products can optimize your processes and deliver superior results!

Visual Guide

Related Products

- Ultra Vacuum Electrode Feedthrough Connector Flange Power Lead for High Precision Applications

- 304 316 Stainless Steel High Vacuum Ball Stop Valve for Vacuum Systems

- Vertical Laboratory Quartz Tube Furnace Tubular Furnace

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

- Ultra High Vacuum Observation Window KF Flange 304 Stainless Steel High Borosilicate Glass Sight Glass

People Also Ask

- Why is the precise regulation of oxygen ratios via mass flow controllers critical for MCTV catalyst yield?

- Why are alumina (Al2O3) sample pans or crucibles essential for DSC testing of titanium alloys? Expert Insights

- What are the components of the circulating water vacuum pump and their functions? Discover Oil-Free Vacuum Solutions

- What are the advantages of high-temperature BSE detectors? Unlock Real-Time Compositional Analysis up to 1000°C

- How do vacuum systems assist in pure thin film growth? Enhance PLD Chemical Purity with Turbo-Molecular Pumps

- What advantages do platinum crucibles offer for KCdCl3 sintering? Ensure Pure, Single-Phase Sample Synthesis

- Why are high-purity alumina crucibles used for phosphor synthesis? Ensure Maximum Luminescence and Spectral Purity

- How do multi-bore high-purity alumina tubes stabilize CV tests? Enhance Data Accuracy with KINTEK Solutions