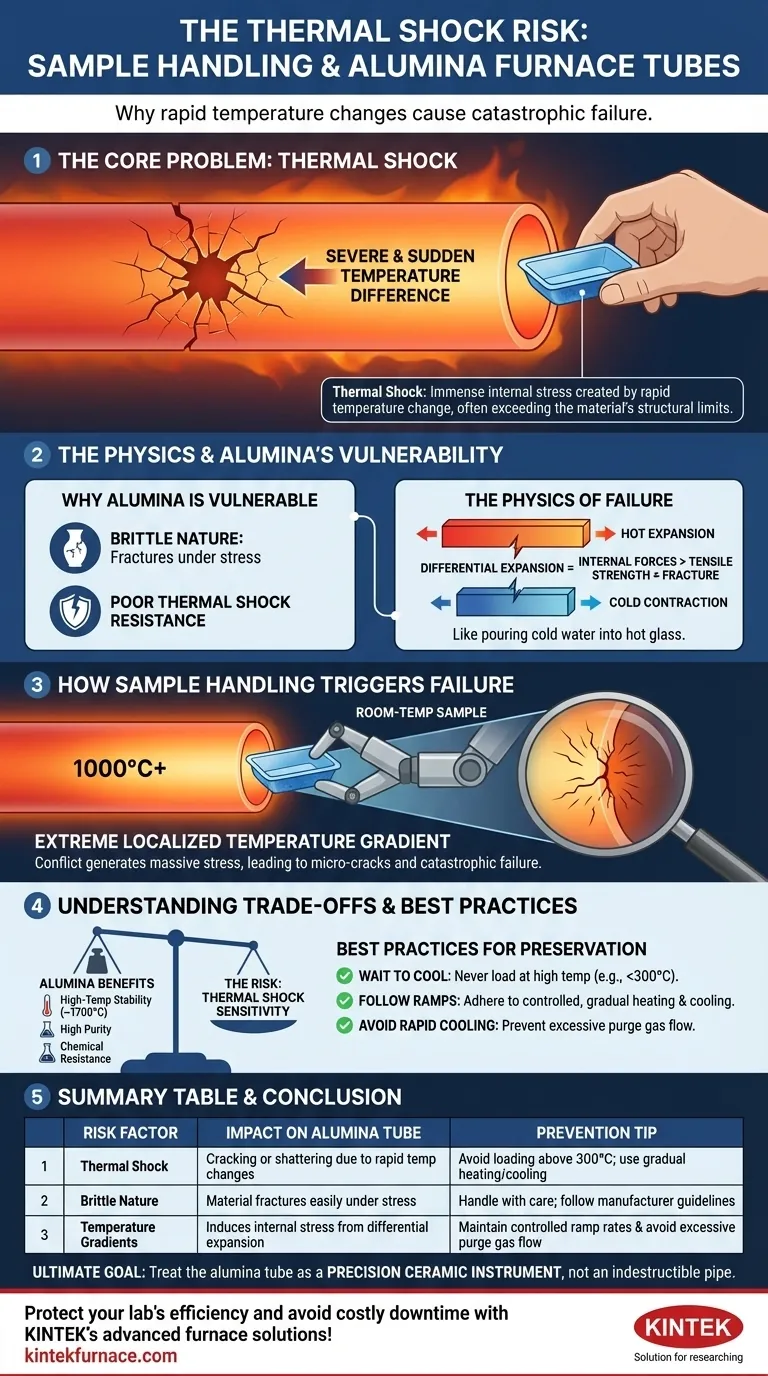

At its core, handling samples at high temperatures introduces a severe and sudden temperature difference to the alumina furnace tube, a phenomenon known as thermal shock. This rapid change creates immense internal stress within the ceramic material. Because alumina is brittle and has poor resistance to thermal shock, this stress can easily exceed the material's structural limits, causing it to crack or shatter.

The fundamental risk is a mismatch between the operational environment and the material's physical properties. Alumina is chosen for its high-temperature stability, not its ability to withstand rapid temperature changes. Subjecting it to thermal shock is the primary cause of premature furnace tube failure.

The Physics of Thermal Shock

What is Thermal Shock?

Thermal shock is the stress induced in a material when it is subjected to a rapid change in temperature. Different parts of the material expand or contract at different rates.

This differential expansion creates internal forces. If these forces are stronger than the material's tensile strength, a fracture will occur. Think of pouring cold water into a hot glass—the sudden contraction of the inner surface while the outer surface remains hot causes it to crack.

Why Alumina is Uniquely Vulnerable

Alumina (Aluminum Oxide, Al₂O₃) is a ceramic prized for its exceptional stability at extreme temperatures and its chemical inertness. However, its properties also make it highly susceptible to thermal shock.

The key factors are its brittle nature and poor thermal shock resistance. Unlike a metal that might bend or deform under stress, a ceramic like alumina will simply fracture.

How Sample Handling Triggers Failure

When you introduce a room-temperature sample boat or push rod into a furnace operating at over 1000°C, you create an extreme, localized temperature gradient on the inner surface of the tube.

That small area of the tube tries to contract instantly while the surrounding material remains expanded by the heat. This conflict generates massive stress in a concentrated spot, leading to the formation of micro-cracks that can quickly propagate into a catastrophic failure.

Understanding the Trade-offs

Why We Use Alumina Despite the Risk

If alumina is so sensitive, you might wonder why it's used at all. The answer lies in its other, highly desirable properties.

Alumina offers an excellent balance of high-temperature performance (withstanding up to ~1700-1800°C), high purity, and chemical resistance. For many scientific and industrial processes, no other material provides this combination at a comparable cost.

The Inevitable Temperature Gradient

It's important to recognize that a temperature difference, or gradient, is inherent to furnace operation. The central heating zone will always be significantly hotter than the ends of the tube.

The danger comes not from the gradient itself, but from the rate of change. The goal of proper furnace operation is to manage these changes slowly and predictably, allowing the entire tube to heat up and cool down as a single unit, minimizing internal stress.

Beyond Sample Handling

While loading a cold sample is a primary risk, other actions can cause the same damaging thermal shock. Forcing a rapid cool-down with an excessive purge gas flow rate, for example, can also create a large enough temperature difference to crack the tube from the inside.

Best Practices for Preserving Your Furnace Tube

To prevent failure, you must operate the furnace in a way that respects the physical limitations of the alumina tube.

- If your primary focus is equipment longevity and safety: Never load or unload samples when the furnace is at a high temperature. Always wait for the tube to cool to a safe temperature (typically below 300°C, but consult your manufacturer's guidelines) before introducing or removing any items.

- If your primary focus is process throughput: The desire for speed cannot override physics. The most efficient process is one that does not fail. Adhere to controlled, gradual heating and cooling ramps to prevent the downtime and cost associated with a fractured tube.

Ultimately, treating your alumina tube as a precision ceramic instrument, not an indestructible pipe, is the key to its long and reliable service.

Summary Table:

| Risk Factor | Impact on Alumina Tube | Prevention Tip |

|---|---|---|

| Thermal Shock | Causes cracking or shattering due to rapid temperature changes | Avoid loading samples above 300°C; use gradual heating/cooling |

| Brittle Nature | Material fractures easily under stress | Handle with care; follow manufacturer guidelines |

| Temperature Gradients | Induces internal stress from differential expansion | Maintain controlled ramp rates and avoid excessive purge gas flow |

Protect your lab's efficiency and avoid costly downtime with KINTEK's advanced furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with high-temperature furnaces like Muffle, Tube, Rotary, Vacuum & Atmosphere, and CVD/PECVD Systems. Our strong deep customization capability ensures precise fit for your unique experimental needs. Contact us today to learn how our reliable equipment can enhance your processes and extend furnace tube lifespan!

Visual Guide

Related Products

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Laboratory Muffle Oven Furnace with Bottom Lifting

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

People Also Ask

- What role does a laboratory tube furnace perform during the carbonization of LCNSs? Achieve 83.8% Efficiency

- What are the material requirements for furnace tubes? Optimize Performance and Safety in High-Temperature Labs

- How is a Vertical Tube Furnace used for fuel dust ignition studies? Model Industrial Combustion with Precision

- What is flash vacuum pyrolysis and how is a tube furnace utilized in this process? Unlock High-Temp Chemical Reactions

- How do roller kilns and tube furnaces differ in their use of Alumina ceramic tubes? Compare Transport vs. Containment