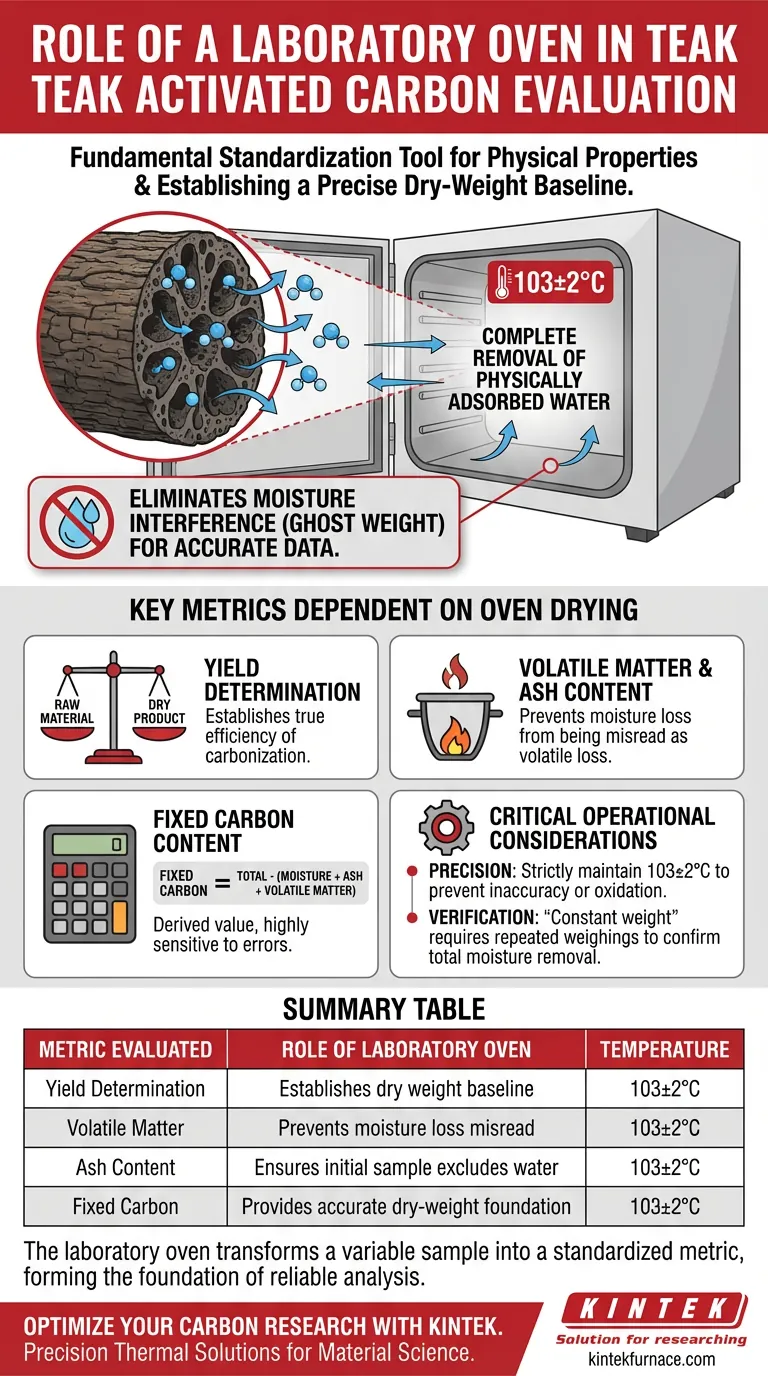

A laboratory oven functions as the fundamental standardization tool in the physical evaluation of teak activated carbon. Its primary role is to subject samples to constant weight treatment at 103±2°C, ensuring the complete removal of physically adsorbed water from the carbon's porous structure.

By eliminating moisture interference, the laboratory oven establishes a precise dry-weight baseline. This step is non-negotiable for calculating accurate values for yield, volatile matter, ash content, and fixed carbon.

Establishing the Baseline for Physical Analysis

The Mechanism of Constant Weight Treatment

Activated carbon derived from teak is naturally porous and hygroscopic, meaning it readily absorbs moisture from the environment. To evaluate the material effectively, you must first strip away this external variable.

The laboratory oven provides a controlled environment heated to 103±2°C. This specific temperature range is sufficient to evaporate water without altering the chemical structure of the carbon itself.

Eliminating Moisture Interference

If moisture is present during weighing, it acts as a "ghost weight." This leads to inflated mass readings that do not reflect the actual amount of carbon material.

The oven ensures that the sample reaches a "constant weight," meaning all physically adsorbed water has been driven off. This creates a reliable dry baseline for all subsequent physical property tests.

Key Metrics Dependent on Oven Drying

Yield Determination

The yield calculation measures the efficiency of the carbonization process.

To determine the true yield of teak activated carbon, you must compare the dry weight of the final product against the raw material. Any moisture remaining in the pores will artificially inflate the yield percentage.

Volatile Matter and Ash Content

Assessing volatile matter and ash content requires burning off specific components of the carbon.

These tests rely on differential weighing. If the starting sample contains moisture, the initial weight loss will be misattributed to volatile matter, skewing the results.

Fixed Carbon Content

Fixed carbon is not measured directly; it is a value calculated by subtracting moisture, ash, and volatile matter from the total.

Because this is a derived value, it is highly sensitive to errors in the other metrics. Accurate oven drying is the only way to ensure the fixed carbon calculation remains valid.

Critical Operational Considerations

The Importance of Temperature Precision

The reference standard specifically calls for a temperature of 103±2°C.

If the oven fluctuates below this range, moisture may remain in deep pores, leading to inaccurate data. If it exceeds this range significantly, you risk oxidizing the carbon before the actual testing begins.

Verification of Constant Weight

It is not enough to simply place the sample in the oven for a set time.

The term "constant weight" implies a process of checking. The sample is properly prepared only when repeated weighings show no further loss of mass, confirming total moisture removal.

Ensuring Precision in Your Analysis

To guarantee the integrity of your teak activated carbon evaluation, prioritize the drying phase.

- If your primary focus is Data Accuracy: Strictly maintain the oven temperature at 103±2°C to prevent moisture from skewing yield and ash calculations.

- If your primary focus is Process Standardization: Ensure the sample reaches a verified constant weight before proceeding to any destructive testing.

The laboratory oven transforms a variable sample into a standardized metric, forming the foundation of all reliable activated carbon characterization.

Summary Table:

| Metric Evaluated | Role of Laboratory Oven | Temperature Requirement |

|---|---|---|

| Yield Determination | Establishes dry weight baseline to calculate efficiency | 103±2°C |

| Volatile Matter | Prevents moisture loss from being misread as volatile loss | 103±2°C |

| Ash Content | Ensures initial sample mass excludes physically adsorbed water | 103±2°C |

| Fixed Carbon | Provides the accurate dry-weight foundation for calculation | 103±2°C |

Optimize Your Carbon Research with KINTEK

Precision is the foundation of material science. Whether you are evaluating teak activated carbon or developing new porous materials, KINTEK provides the advanced thermal solutions you need. Backed by expert R&D and manufacturing, we offer high-performance Muffle, Tube, Rotary, Vacuum, and CVD systems, all customizable to meet your unique laboratory specifications. Ensure your data integrity with equipment designed for absolute temperature stability. Contact our specialists today to find the perfect furnace for your application!

Visual Guide

References

- Johanes Pramana Gentur SUTAPA, Robertus Danu PRIYAMBODO. Utilization of Sapwood Waste of Fast-Growing Teak in Activated Carbon Production and Its Adsorption Properties. DOI: 10.5658/wood.2024.52.2.118

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1200℃ Muffle Oven Furnace for Laboratory

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Vacuum Dental Porcelain Sintering Furnace for Dental Laboratories

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

People Also Ask

- What is the primary purpose of a vacuum pump in photocatalytic CO2 reduction? Ensure Pure Environments for Accurate Data

- How do alumina ceramic tubes compare to quartz ceramic tubes in terms of thermal properties? Choose the Right Tube for High-Temp Success

- How does a laboratory blast drying oven facilitate the treatment of Au/ZnO/In2O3 precursor precipitates? Key Benefits

- What role does a high-density MgO crucible play in slag reduction experiments? Ensure Pure Results at 1600°C

- What is the technical necessity of using a glass boat in a pyrolysis furnace? Precision in Thermal Decomposition

- What substances are prohibited from being introduced into the furnace chamber? Prevent Catastrophic Failure

- How do repeat sintering processes and specialized sintering molds address the technical challenges of manufacturing oversized flywheel rotor components? Expand Scale and Integrity

- Why is a standard Quartz Crystal Sensor required during germanium evaporation for nanocrystal fabrication?