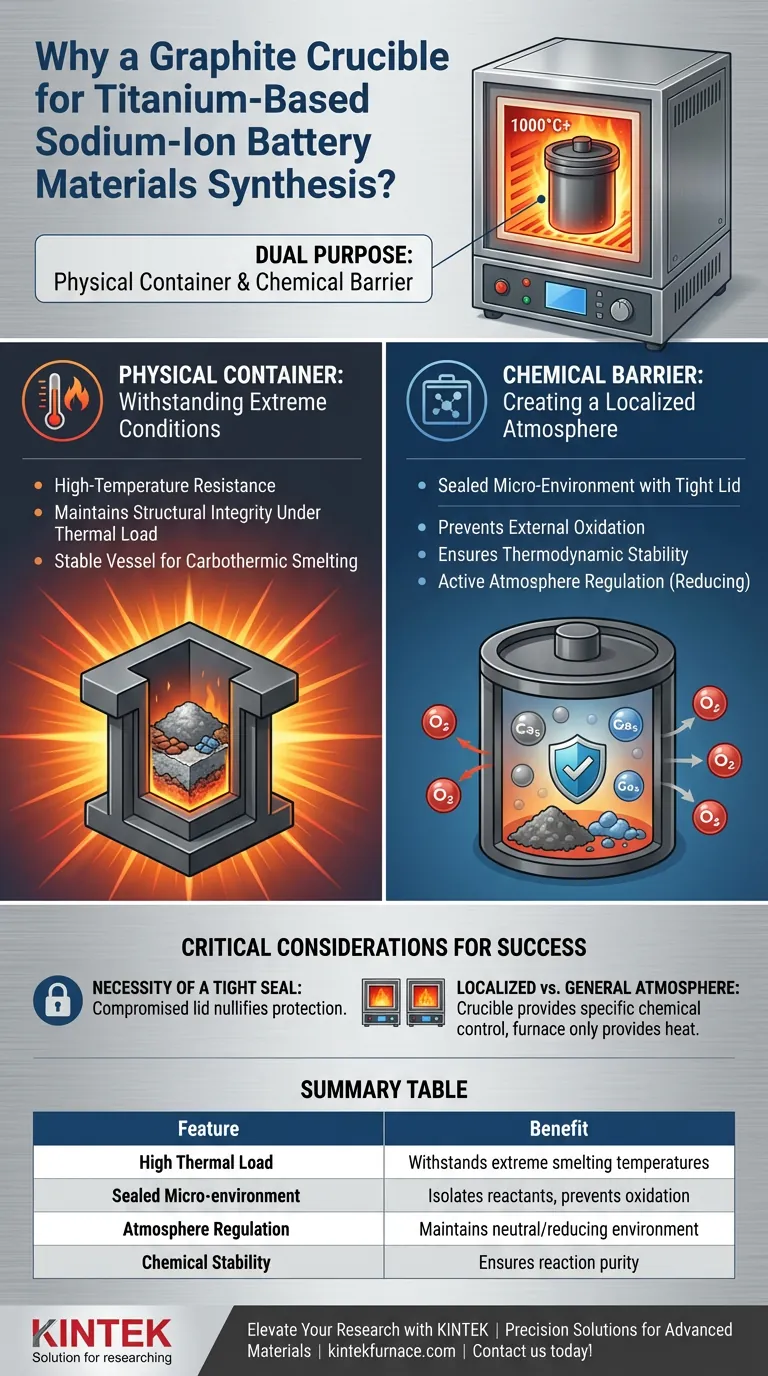

Graphite crucibles are selected primarily for their ability to actively regulate the reaction atmosphere while withstanding extreme heat. In the synthesis of titanium-based sodium-ion battery materials, specifically during carbothermic smelting, these vessels serve a dual purpose: they act as a physical container and a chemical barrier that generates a localized reducing or neutral micro-environment.

The graphite crucible does not merely hold the reactants; it isolates them. By creating a shielded micro-environment, it prevents external oxidation and ensures the carbothermic reduction proceeds strictly according to the intended thermodynamic design.

The Functional Role of the Crucible

Withstanding Extreme Conditions

The primary requirement for this synthesis is high-temperature resistance.

Graphite is chosen because it maintains structural integrity under the intense thermal loads required for carbothermic smelting, serving as a stable vessel for the raw materials.

Creating a Localized Atmosphere

When equipped with a tight graphite lid, the crucible functions as more than a container.

It effectively creates a sealed chamber within the larger muffle furnace. This establishes a specific "micro-environment" that is distinct from the general atmosphere of the furnace.

Chemical Control and Protection

Preventing Material Oxidation

Titanium-based materials are often sensitive to oxygen during synthesis.

The graphite crucible prevents the raw materials from interacting with external air. This physical isolation is critical to avoid unwanted oxidation that would degrade the quality of the final battery material.

Ensuring Thermodynamic Stability

For the synthesis to succeed, the chemical reaction must follow a precise thermodynamic pathway.

By maintaining a neutral or reducing atmosphere, the graphite crucible ensures the carbothermic reduction reaction occurs exactly as calculated, without interference from atmospheric oxygen.

Critical Considerations for Success

The Necessity of a Tight Seal

The benefits of the graphite crucible are entirely dependent on the integrity of the lid.

If the graphite lid is not tight, the localized micro-environment is compromised. This allows external air to infiltrate, effectively nullifying the protective benefits of the vessel.

localized vs. General Atmosphere

It is important to understand that the crucible creates a localized environment.

While the muffle furnace provides the heat, the crucible provides the chemical control. Relying solely on the furnace atmosphere without the specific protection of the graphite vessel may lead to inconsistent results.

Optimizing Your Synthesis Process

To ensure the highest quality titanium-based sodium-ion materials, align your equipment choice with your specific processing needs:

- If your primary focus is Phase Purity: Ensure the graphite lid is perfectly fitted to prevent any oxygen ingress that could form secondary phases.

- If your primary focus is Reaction Control: Rely on the graphite crucible to maintain the strict reducing environment required for the carbothermic pathway.

Success in this synthesis relies on treating the crucible not just as a holder, but as an active component in the chemical process.

Summary Table:

| Feature | Benefit for Titanium-Based Materials |

|---|---|

| High Thermal Load | Withstands extreme carbothermic smelting temperatures without structural failure. |

| Sealed Micro-environment | Isolates reactants from external air to prevent unwanted oxidation of sensitive titanium. |

| Atmosphere Regulation | Maintains a neutral/reducing environment crucial for the carbothermic thermodynamic pathway. |

| Chemical Stability | Ensures reaction purity by preventing interference from muffle furnace atmosphere gases. |

Elevate Your Battery Material Research with KINTEK

Precision in sodium-ion battery synthesis requires more than just heat—it requires perfect atmospheric control. KINTEK provides high-performance laboratory solutions tailored for advanced material science. Backed by expert R&D and manufacturing, we offer high-quality Muffle, Tube, Rotary, Vacuum, and CVD systems, along with customizable high-temperature furnace accessories designed to meet your unique thermodynamic requirements.

Don't let oxidation compromise your phase purity. Contact us today to find the perfect customizable high-temp solution for your lab!

Visual Guide

References

- Formation of Electrode Materials in the Process of Carbothermic Flux Smelting of Ilmenite Concentrate and Hydrothermal Refining of Titanium Slag. DOI: 10.3390/pr13051554

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

- 1400℃ Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

People Also Ask

- What roles do metal shielding disks and heat shields play in in-situ SEM? Ensure Precision & Protect Your Lab Equipment

- Why is firing cotton used as a cushion between the ceramic sample and the tray during sintering? Prevent Distortion

- What are the main composition percentages of alumina tubes? Optimize Performance for High-Temperature Applications

- What role does a PTFE-lined high-pressure autoclave play in synthesis of ZnO nanorods? Key Benefits & Growth Factors

- What is the function of a laboratory hydraulic press in LLZO green body prep? Ensure High Density and Ionic Conductivity

- What is the maximum pressure achievable by the circulating water vacuum pump? Discover Its Vacuum Limits

- What role do high-purity graphite crucibles play in Boron Carbide sintering? Optimize Ceramic Purity and Density

- How does the optical clarity of quartz tubes benefit laboratory processes? Enhance Control and Accuracy in High-Temp Experiments