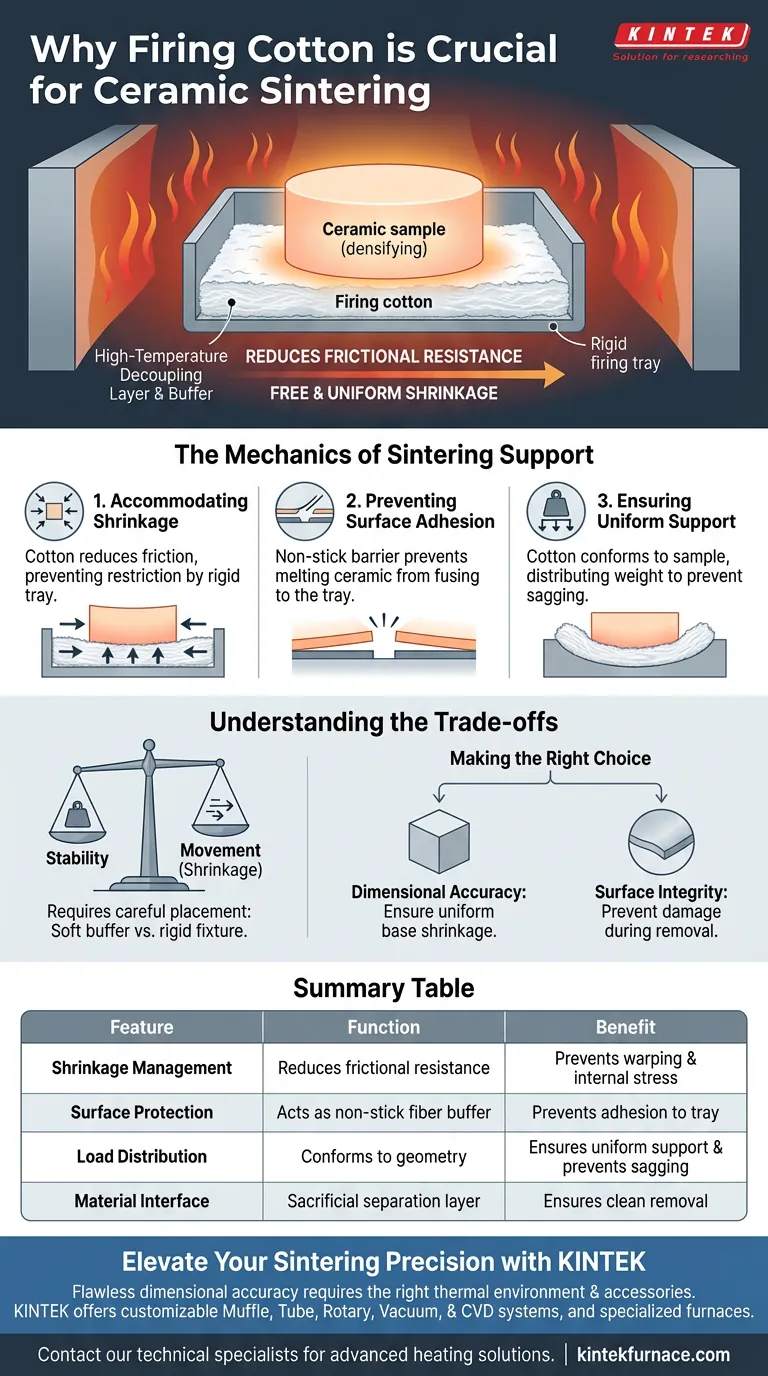

Firing cotton functions as a high-temperature decoupling layer. It creates a soft, fibrous buffer between the delicate ceramic sample and the rigid firing tray during the sintering process. This separation is essential to prevent the ceramic from sticking to the tray while ensuring the material is supported evenly across its base.

The central role of firing cotton is to reduce frictional resistance. By allowing the ceramic to shrink freely and uniformly as it densifies, the cotton prevents the structural distortion and stress that occur when a sample is restricted by a rigid surface.

The Mechanics of Sintering Support

Accommodating Physical Shrinkage

Ceramics undergo significant physical shrinkage as they are fired. If the sample rests directly on a rigid tray, the friction between the two surfaces can restrict this movement.

Firing cotton reduces this frictional resistance at the base of the sample. This allows the veneered ceramic to contract naturally and freely. Without this "floating" effect, the material could experience tension, leading to warping or internal stress.

Preventing Surface Adhesion

At elevated temperatures, ceramic materials can become reactive or sticky. Direct contact with the firing tray risks the sample adhering or fusing to the tray surface.

The cotton serves as a high-temperature resistant fiber buffer. It acts as a sacrificial interface that physically separates the melting ceramic from the tray, ensuring the sample can be removed cleanly after cooling.

Ensuring Uniform Support

rigid firing trays provide a flat, unforgiving surface. Complex ceramic shapes may not make perfect contact with the tray, creating pressure points.

Firing cotton conforms to the geometry of the sample. It offers uniform support, distributing the weight of the ceramic evenly to prevent sagging or deformation during the high-heat phase.

Understanding the Trade-offs

Stability vs. Movement

While the primary goal of firing cotton is to allow movement (shrinkage), this introduces a variable in stability.

Because the material is a soft buffer rather than a rigid fixture, it requires careful placement. The cotton must be sufficient to cushion the sample but stable enough to prevent the object from shifting or tipping over as the fibers compress under heat.

Making the Right Choice for Your Goal

To ensure the integrity of your ceramic samples, consider the specific function the cotton serves relative to your outcome.

- If your primary focus is Dimensional Accuracy: Use firing cotton to ensure the base of the sample shrinks at the same rate as the body, preventing distortion.

- If your primary focus is Surface Integrity: Rely on the cotton to act as a non-stick barrier, preventing damage to the bottom of the ceramic during removal.

By neutralizing friction, firing cotton transforms the sintering tray from a rigid constraint into a supportive platform.

Summary Table:

| Feature | Function of Firing Cotton | Benefit for Ceramics |

|---|---|---|

| Shrinkage Management | Reduces frictional resistance | Prevents warping and internal stress |

| Surface Protection | Acts as a non-stick fiber buffer | Prevents adhesion to the firing tray |

| Load Distribution | Conforms to sample geometry | Ensures uniform support and prevents sagging |

| Material Interface | Sacrificial separation layer | Ensures clean removal after cooling |

Elevate Your Sintering Precision with KINTEK

Achieving flawless dimensional accuracy requires the right thermal environment and accessories. Backed by expert R&D and manufacturing, KINTEK offers a comprehensive range of Muffle, Tube, Rotary, Vacuum, and CVD systems, along with specialized lab high-temp furnaces—all fully customizable to your unique sintering needs.

Don't let friction or uneven heating compromise your ceramic integrity. Contact our technical specialists today to discover how our advanced heating solutions can optimize your laboratory results.

Visual Guide

References

- Moritz Hoffmann, Bogna Stawarczyk. Mechanical Properties of High- and Low-Fusing Zirconia Veneering Ceramics Fired on Different Trays and Substrates. DOI: 10.3390/ma17102261

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- Why is an air-cooled stainless steel sampling probe utilized? Ensure Accurate High-Temp Combustion Analysis

- Why is a high vacuum pumping system necessary during the preparation of Sb2S3? Ensure High-Purity Semiconductor Films

- What are the maximum working pressure specifications for water circulating vacuum pumps? Ensure Safe Operation and Avoid Failure

- Why is a vacuum suction system required during the exhaust stage of rice straw-based charcoal carbonization?

- What is the primary function of an alumina crucible in preparing B2O3–ZnO–BaO shielding glass? Process Secrets Revealed

- What is the purpose of configuring a hot gas filter within a Catalytic Hydropyrolysis (CHP) process? Ensure Reactor Life

- What are the typical applications of a circulating water vacuum pump? Essential for Lab Efficiency and Cost Savings

- How does a laboratory drying oven function in catalyst synthesis? Secure Precision Metal Precursor Stabilization