At its core, a circulating water vacuum pump is a workhorse for generating a rough vacuum in laboratory and small-scale industrial settings. Its primary applications involve processes that benefit from reduced atmospheric pressure, such as evaporation, distillation, crystallization, drying, sublimation, vacuum filtration, and degassing. These pumps are staples in university, research, and industrial labs across fields like chemistry, pharmaceuticals, and biology.

The true value of a circulating water vacuum pump lies not in its power, but in its simplicity and reliability. It provides a sufficient, low-cost vacuum for countless common lab procedures without the cost, contamination risk, and maintenance demands of oil-based pumps.

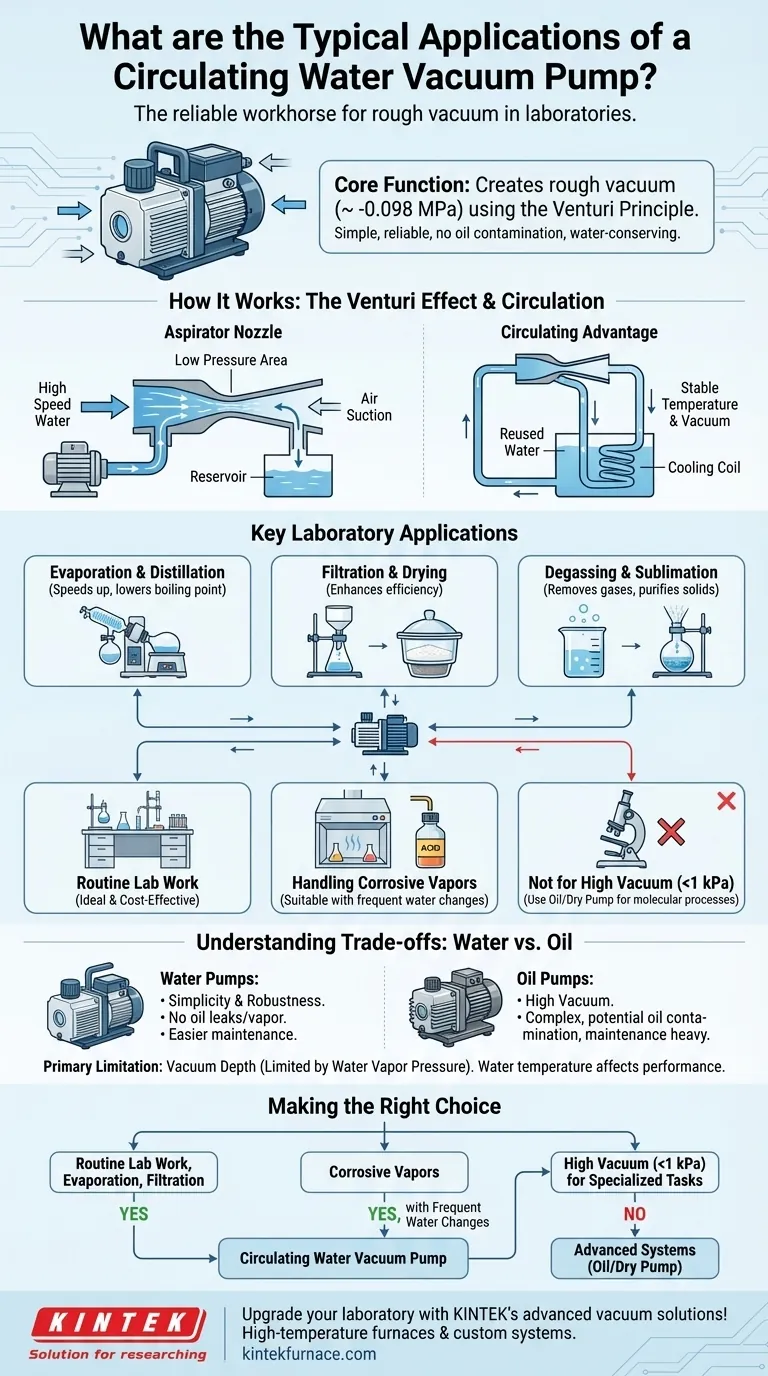

The Core Function: How It Creates a Vacuum

A circulating water vacuum pump doesn't use complex mechanical pistons or scrolls. Instead, it relies on a simple, elegant physical principle to create negative pressure.

How It Works: The Venturi Principle

The heart of the pump is an aspirator, which works on the Venturi effect. Water from a reservoir is pumped at high speed through a constricted nozzle. As the water accelerates through this tight space, its pressure drops dramatically.

This area of low pressure creates a suction force that pulls in air and other gases from the connected apparatus (e.g., a distillation flask or a filter funnel). The air is entrained in the water stream and carried away.

The "Circulating" Advantage

Unlike a simple tap-water aspirator that dumps water down the drain, a circulating pump reuses the same water from an integrated tank.

This design conserves thousands of liters of water, provides a more stable vacuum level as water temperature stabilizes, and helps contain any soluble vapors that might be pulled from the chemical process.

Key Laboratory Applications in Detail

The "rough vacuum" (typically around -0.098 MPa or 2 kPa) created by these pumps is ideal for accelerating many fundamental lab processes.

Speeding Up Evaporation & Distillation

By reducing the pressure inside a vessel like a rotary evaporator, you lower the boiling point of solvents. This allows for gentle and rapid removal of solvents without having to apply excessive, potentially damaging heat to the sample.

Enhancing Filtration & Drying

For vacuum filtration with a Büchner funnel, the pump rapidly pulls the liquid (filtrate) through the filter paper, leaving the solid behind. This is significantly faster and more efficient than relying on gravity alone. Similarly, when drying a sample in a vacuum desiccator, the pump removes air and solvent vapors, speeding up the drying process.

Degassing and Sublimation

A vacuum is highly effective at removing dissolved gases from liquids (degassing), a critical step in preparing solvents for sensitive reactions or analytical techniques like HPLC. It also enables sublimation, a purification technique where a solid is turned directly into a gas under vacuum and then re-deposited as a pure solid on a cold surface.

Understanding the Trade-offs: Water vs. Oil Pumps

Choosing a vacuum source depends entirely on the goal of your experiment. A water pump is not a universal solution, and understanding its place relative to other pump types is critical.

The Case for Water Pumps: Simplicity & Robustness

Compared to oil-sealed rotary vane pumps, water pumps are far simpler. They have fewer moving parts, are not prone to messy oil leaks, and present no risk of oil vapor contaminating your experiment. They are also generally more economical, easier to clean, and can handle corrosive vapors with proper maintenance.

The Primary Limitation: Vacuum Depth

The single most important limitation of a water pump is its ultimate vacuum. The vacuum it can achieve is physically limited by the vapor pressure of the water in the reservoir. As the water gets warmer, its vapor pressure increases, and the quality of the vacuum decreases. These pumps cannot achieve the high vacuum levels required for processes like molecular distillation or operating electron microscopes.

Essential Maintenance Considerations

To maintain performance, the water in the reservoir must be replaced regularly. If you are pumping corrosive gases (like acid vapors), the water will become acidic and must be changed frequently to prevent damage to the pump's internal components. Keeping the water clean is the single most effective step for ensuring a consistent vacuum.

Making the Right Choice for Your Goal

Use this guide to determine if a circulating water vacuum pump is the right tool for your specific task.

- If your primary focus is routine lab work: For rotary evaporation, filtration, or standard distillations, a circulating water vacuum pump is the ideal, cost-effective, and reliable choice.

- If your primary focus is handling corrosive vapors: A water pump is a suitable option, provided you commit to a frequent water replacement schedule to neutralize absorbed contaminants.

- If your primary focus is achieving a high vacuum (<1 kPa): A water pump is insufficient for this goal. You must use a more advanced system, such as an oil-sealed or dry scroll vacuum pump.

By understanding its principles and limitations, you can leverage the circulating water vacuum pump as a reliable and economical tool for a vast range of scientific applications.

Summary Table:

| Application | Key Benefit | Ideal For |

|---|---|---|

| Evaporation & Distillation | Lowers boiling points for gentle solvent removal | Routine lab work like rotary evaporation |

| Filtration & Drying | Speeds up liquid removal in processes like Büchner funnel filtration | Standard filtration and sample drying |

| Degassing & Sublimation | Removes dissolved gases and enables solid purification | Preparing solvents for sensitive reactions |

| Handling Corrosive Vapors | Suitable with proper maintenance and water changes | Labs dealing with acids or contaminants |

Upgrade your laboratory with KINTEK's advanced vacuum solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse labs with reliable high-temperature furnaces and more. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by strong deep customization to meet your unique experimental needs. Whether you're in chemistry, pharmaceuticals, or biology, our solutions enhance efficiency and precision. Contact us today to discuss how we can support your specific applications and drive your research forward!

Visual Guide

Related Products

- Ultra Vacuum Electrode Feedthrough Connector Flange Power Lead for High Precision Applications

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- Laboratory Vacuum Tilt Rotary Tube Furnace Rotating Tube Furnace

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- 304 316 Stainless Steel High Vacuum Ball Stop Valve for Vacuum Systems

People Also Ask

- What role does a mass flow controller (MFC) play in plasma-based aluminum reduction? Precision Control for High Yields

- Why are high-purity alumina crucibles used for MAX phase sintering? Ensure Purity in High-Temperature Synthesis

- Why is a Mass Flow Controller (MFC) important for gas-phase corrosion research? Ensure Data Integrity & Precision

- What are the technical requirements for the Quartz Boat used as a precursor container in the CVD growth of 2D In2Se3?

- How does insulation affect laboratory furnace design? Optimize Thermal Performance and Safety

- What are the main features of a water circulating vacuum pump compared to a desktop pump? Discover Key Differences for Your Lab

- What is the function of graphite stirring rods in aluminum casting? Achieve Perfect Alloy Homogenization

- Why is a mass flow controller essential in the tracer method? Precision Data for Pyrolysis Gas Flow