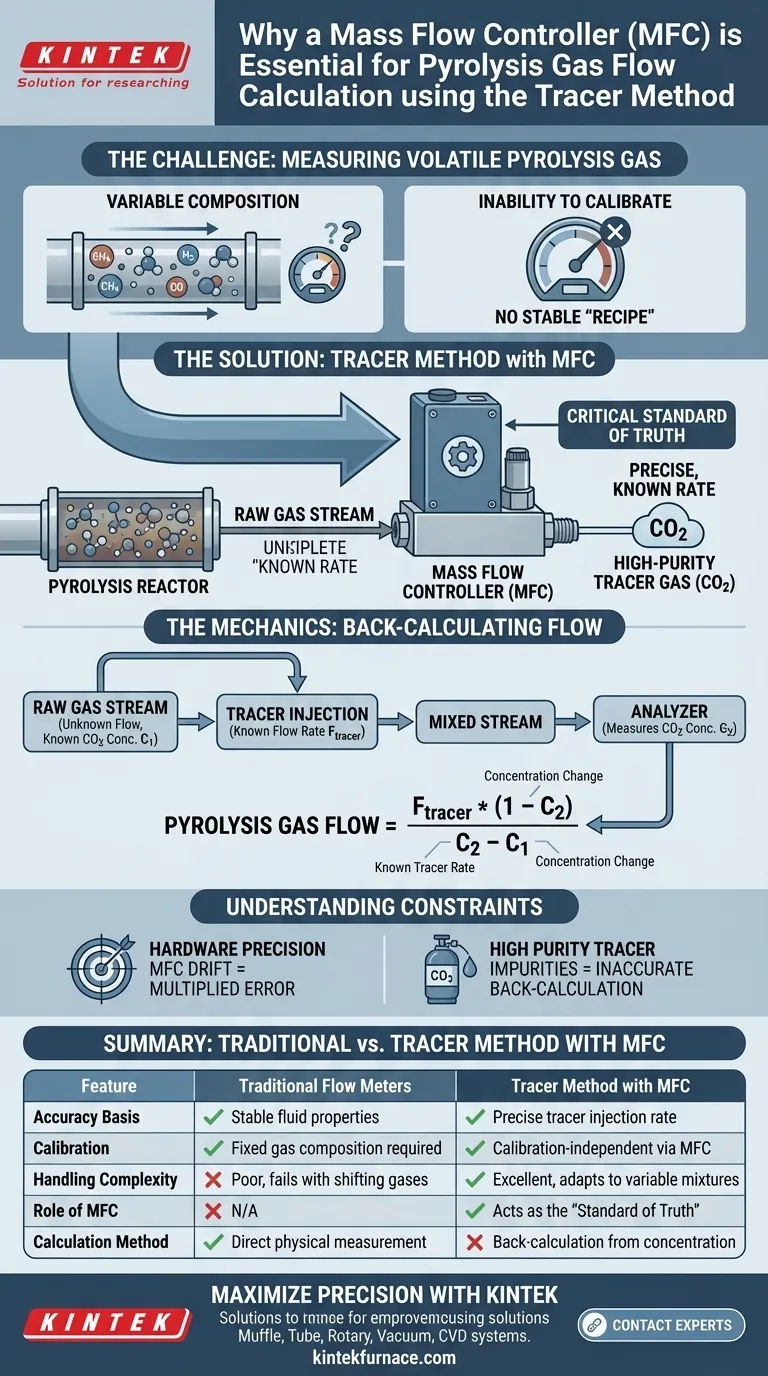

The mass flow controller (MFC) acts as the critical standard of truth in an otherwise volatile environment. In the tracer method, the MFC is responsible for injecting a known, precise quantity of high-purity carbon dioxide into the raw gas stream at the reactor outlet. This controlled injection provides the fixed variable necessary to mathematically determine the flow rate of the complex pyrolysis gas.

By injecting a tracer gas at a strictly controlled rate, the mass flow controller allows engineers to bypass the limitations of traditional meters. It converts a difficult physical measurement problem into a solvable mathematical equation based on concentration changes.

Why Traditional Measurement Fails

The Challenge of Variable Composition

Standard flow meters rely on stable fluid properties to generate accurate readings. However, pyrolysis gas is a complex mixture with a composition that changes continuously during production.

Inability to Calibrate

Because the "recipe" of the gas stream is constantly shifting, traditional meters cannot be calibrated effectively. They struggle to provide accurate data, necessitating an alternative approach like the tracer method.

The Mechanics of the Tracer Method

Precision Injection

The tracer method relies entirely on the introduction of a high-purity tracer gas, typically carbon dioxide. The mass flow controller ensures this tracer is introduced at a perfectly steady, known rate.

Creating a Reference Point

Without the MFC, the amount of tracer entering the system would be an unknown variable. The MFC turns this injection into a fixed constant, which is the foundation for the entire calculation.

Back-Calculating Flow

The system measures the concentration of carbon dioxide in the stream before the injection and compares it to the concentration after the injection. Because the MFC ensures the amount of added CO2 is known, the change in concentration allows engineers to back-calculate the total flow rate of the pyrolysis gas.

Understanding the Constraints

Reliance on Hardware Precision

The accuracy of the calculated gas flow is directly proportional to the accuracy of the mass flow controller. Any drift or error in the MFC will result in a multiplied error in the final flow calculation.

The Necessity of High Purity

The method assumes the tracer gas is high-purity. If the injected carbon dioxide contains impurities, the known input variable is compromised, leading to inaccurate back-calculations.

Making the Right Choice for Your Goal

To effectively utilize the tracer method for pyrolysis, consider the following:

- If your primary focus is Data Accuracy: Invest in a high-precision mass flow controller, as it is the single most critical hardware component in this measurement loop.

- If your primary focus is Process Stability: Ensure the tracer gas (carbon dioxide) is of verified high purity to prevent introducing unknown variables into your calculation.

The mass flow controller transforms the chaotic output of a pyrolysis reactor into quantifiable data by providing the one constant required to solve the flow equation.

Summary Table:

| Feature | Traditional Flow Meters | Tracer Method with MFC |

|---|---|---|

| Accuracy Basis | Stable fluid properties | Precise tracer injection rate |

| Calibration | Fixed gas composition required | Calibration-independent via MFC |

| Handling Complexity | Poor; fails with shifting gases | Excellent; adapts to variable mixtures |

| Role of MFC | N/A | Acts as the "Standard of Truth" |

| Calculation Method | Direct physical measurement | Back-calculation from concentration |

Maximize Your Pyrolysis Precision with KINTEK

Achieving accurate flow measurements in volatile environments requires hardware you can trust. KINTEK provides the high-precision equipment necessary to transform chaotic reactor outputs into quantifiable, actionable data.

Backed by expert R&D and world-class manufacturing, we offer a comprehensive range of lab solutions including Muffle, Tube, Rotary, Vacuum, and CVD systems, all of which can be customized to your unique research or production needs. Whether you are refining the tracer method or scaling your thermal process, KINTEK delivers the stability and accuracy your facility demands.

Ready to elevate your lab's performance? Contact our experts today to discuss your custom furnace and flow control requirements!

Visual Guide

References

- Zsolt Dobó, Gábor Nagy. Production of Biochar by Pyrolysis of Food Waste Blends for Negative Carbon Dioxide Emission. DOI: 10.3390/en18010144

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 304 316 Stainless Steel High Vacuum Ball Stop Valve for Vacuum Systems

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Heat Treat Sintering and Brazing Furnace

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

People Also Ask

- Why is an air-cooled stainless steel sampling probe utilized? Ensure Accurate High-Temp Combustion Analysis

- What are the key properties of alumina ceramic tubes? Unlock High-Temp Performance for Your Lab

- What roles do high-purity graphite molds play during the Spark Plasma Sintering (SPS) of Ba0.95La0.05FeO3-δ? Essential Guide

- What are the advantages of using an infrared thermograph over traditional thermocouples in Plasma Flash Sintering (PFS)?

- What is the necessity of a cylindrical condenser in a microwave-assisted metal reduction system? Key Protection Insights

- How does a vacuum sealing device protect the experimental environment? Ensure Purity in High-Temp Compression Tests

- What function does a planetary ball mill perform in LiFePO4/C synthesis? Optimize Battery Material Conductivity

- How does the choice of high-purity ceramic crucibles impact glass phantoms? Unlock Optical Precision in Sintering