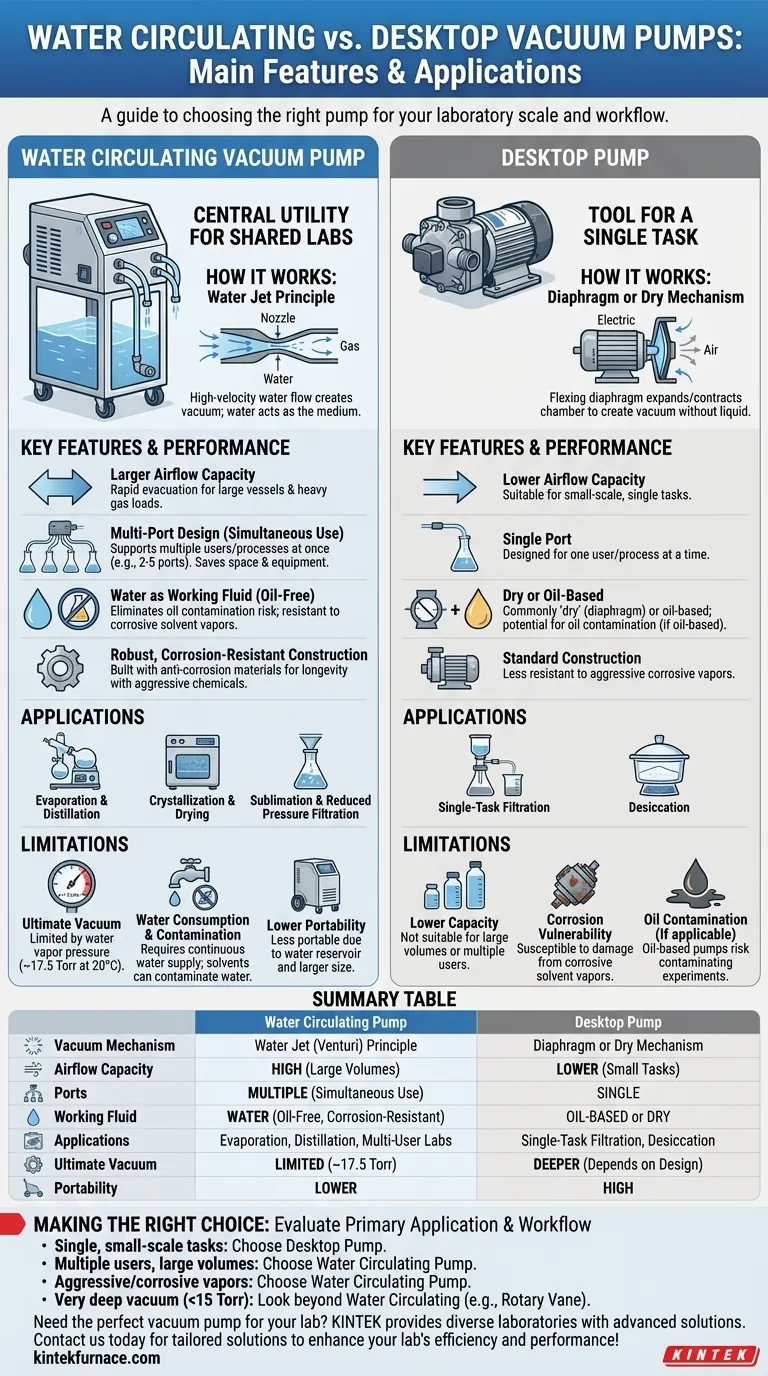

In a laboratory setting, a water circulating vacuum pump is fundamentally different from a standard desktop pump. Its main features include a significantly larger airflow capacity, a multi-port design allowing several processes to run simultaneously, and its use of water as the working fluid, which makes it inherently resistant to corrosive vapors and eliminates oil contamination.

A desktop pump is a tool for a single task, while a water circulating vacuum pump is a central utility for a shared lab. The choice between them is not about which is "better," but which one matches the scale, chemistry, and workflow of your environment.

The Core Difference: How They Generate a Vacuum

The most significant distinction lies in the underlying mechanism each pump uses to create negative pressure. This principle dictates their performance, applications, and limitations.

The Water Jet Principle

A water circulating vacuum pump operates by using a high-velocity jet of water. As water is pumped through a nozzle (a Venturi jet), its speed increases, causing a sharp drop in pressure according to Bernoulli's principle. This pressure drop pulls in gas from the connected apparatus, creating a vacuum.

The water then acts as the medium to carry away the evacuated gas molecules.

Typical Desktop Pump Mechanisms

Most common desktop lab pumps are "dry" pumps, often using a flexible diaphragm. An electric motor drives a mechanism that repeatedly flexes the diaphragm, expanding and contracting a chamber. This action alternately draws air in from the system and expels it to the atmosphere, creating a vacuum without any liquid.

The Impact of the Working Fluid

The use of water is not incidental; it is central to the pump's character. Because it uses water instead of oil, there is no risk of oil pollution contaminating your experiment, and the pump itself is less susceptible to damage from solvent vapors that are pulled into the vacuum line.

Key Feature Breakdown: Performance and Application

The design of a water circulating pump directly translates to a set of features built for demanding, multi-use environments.

Superior Suction Capacity

These pumps are engineered to provide a larger airflow than typical desktop models. This high flow rate is essential for quickly evacuating large vessels, such as large-scale rotary evaporators or glass reactors, and for maintaining vacuum under heavy gas load.

Multi-Port Functionality

A defining feature is the presence of multiple vacuum ports—often two, four, or even five. These taps can be used independently or in parallel.

This allows multiple students or researchers to conduct experiments simultaneously from a single unit, saving significant lab space and equipment cost.

Built for Demanding Chemical Processes

The combination of high suction and an oil-free design makes these pumps ideal for common chemistry lab procedures. They provide the vacuum conditions needed for:

- Evaporation and Distillation

- Crystallization and Drying

- Sublimation

- Reduced Pressure Filtration

Robust and Corrosion-Resistant Construction

Manufacturers anticipate use with aggressive chemicals. The main engine and key components are often made of stainless steel and other anti-corrosion materials, ensuring longevity and reliability even when exposed to acidic or solvent-rich vapors.

Understanding the Trade-offs

No single solution is perfect for every scenario. It is critical to understand the inherent limitations of a water-circulating design.

Ultimate Vacuum Level

The deepest vacuum a water circulating pump can achieve is physically limited by the vapor pressure of the water being used. As the pressure in the system approaches water's vapor pressure, the water itself will begin to boil, preventing a deeper vacuum. For water at 20°C (68°F), this limit is around 17.5 Torr.

Water Consumption and Contamination

These pumps require a continuous supply of circulating water, which can be a consideration for utility costs. Furthermore, any volatile solvents from your experiment will be pulled into the water, potentially contaminating it and requiring proper disposal protocols.

Lower Portability

While often on wheels for easy movement within a lab, their reliance on a water reservoir and larger size makes them less portable than a small, self-contained desktop diaphragm pump.

Making the Right Choice for Your Goal

To select the appropriate pump, evaluate your primary application and workflow.

- If your primary focus is single, small-scale filtration or desiccation: A compact desktop diaphragm pump is likely more efficient and economical for your needs.

- If your primary focus is supporting multiple users or large-volume processes: A water circulating pump offers the necessary high capacity and multi-port flexibility.

- If your primary focus is working with aggressive or corrosive vapors: The oil-free, corrosion-resistant design of a water circulating pump is the safer and more durable choice.

- If your primary focus is achieving a very deep vacuum (below ~15 Torr): You will need to look beyond a water circulating pump to a rotary vane or other high-vacuum pump technology.

Understanding these core differences in design and application ensures you select the right tool for your specific scientific objective.

Summary Table:

| Feature | Water Circulating Vacuum Pump | Desktop Pump |

|---|---|---|

| Vacuum Mechanism | Water jet (Venturi) principle | Diaphragm or dry mechanism |

| Airflow Capacity | High, suitable for large volumes | Lower, for small-scale tasks |

| Ports | Multiple (e.g., 2-5), for simultaneous use | Typically single port |

| Working Fluid | Water, oil-free, corrosion-resistant | Often oil-based or dry, may contaminate |

| Applications | Evaporation, distillation, multi-user labs | Single-task filtration, desiccation |

| Ultimate Vacuum | Limited by water vapor pressure (~17.5 Torr) | Can achieve deeper vacuum if designed for it |

| Portability | Lower, requires water supply | High, compact and self-contained |

Need the perfect vacuum pump for your lab? Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by our strong deep customization capability to precisely meet unique experimental requirements. Contact us today to discuss how we can enhance your lab's efficiency and performance with tailored solutions!

Visual Guide

Related Products

- Ultra Vacuum Electrode Feedthrough Connector Flange Power Lead for High Precision Applications

- CF KF Flange Vacuum Electrode Feedthrough Lead Sealing Assembly for Vacuum Systems

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- Molybdenum Vacuum Heat Treat Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

People Also Ask

- What is the function of a water-cooled jacket on a sampling probe? Optimize Atomization and Protect Hardware

- What are the material requirements for a quartz boat in APVT? Ensure High-Purity Sb2Se3 Nanowire Growth

- Why is an alundum crucible necessary for the melting and casting of FeAl alloys? Ensure Maximum Purity and Stability

- Why must a rotary vane vacuum pump be integrated into the curing platform for phenolic laminates? Key to Void-Free Parts

- What is the primary function of the vacuum pump system in the magnesium powder evaporation process? Ensure High Purity & Efficiency

- Why is a rotary evaporator used to process separated fractions in hydrotreated coal tar analysis? Enhance Sample Purity

- What is the function of a specifically designed annealing vessel in SVA? Enhance Your Film Crystallization Today

- What is the purpose of configuring a hot gas filter within a Catalytic Hydropyrolysis (CHP) process? Ensure Reactor Life