The necessity of using a ceramic crucible for thermal processing lies in its ability to withstand extreme conditions without compromising the sample. It acts as the essential carrier vessel for high-temperature treatments, specifically designed to convert dried leachates from sugarcane bagasse into fine silica powders while maintaining the chemical integrity of the material.

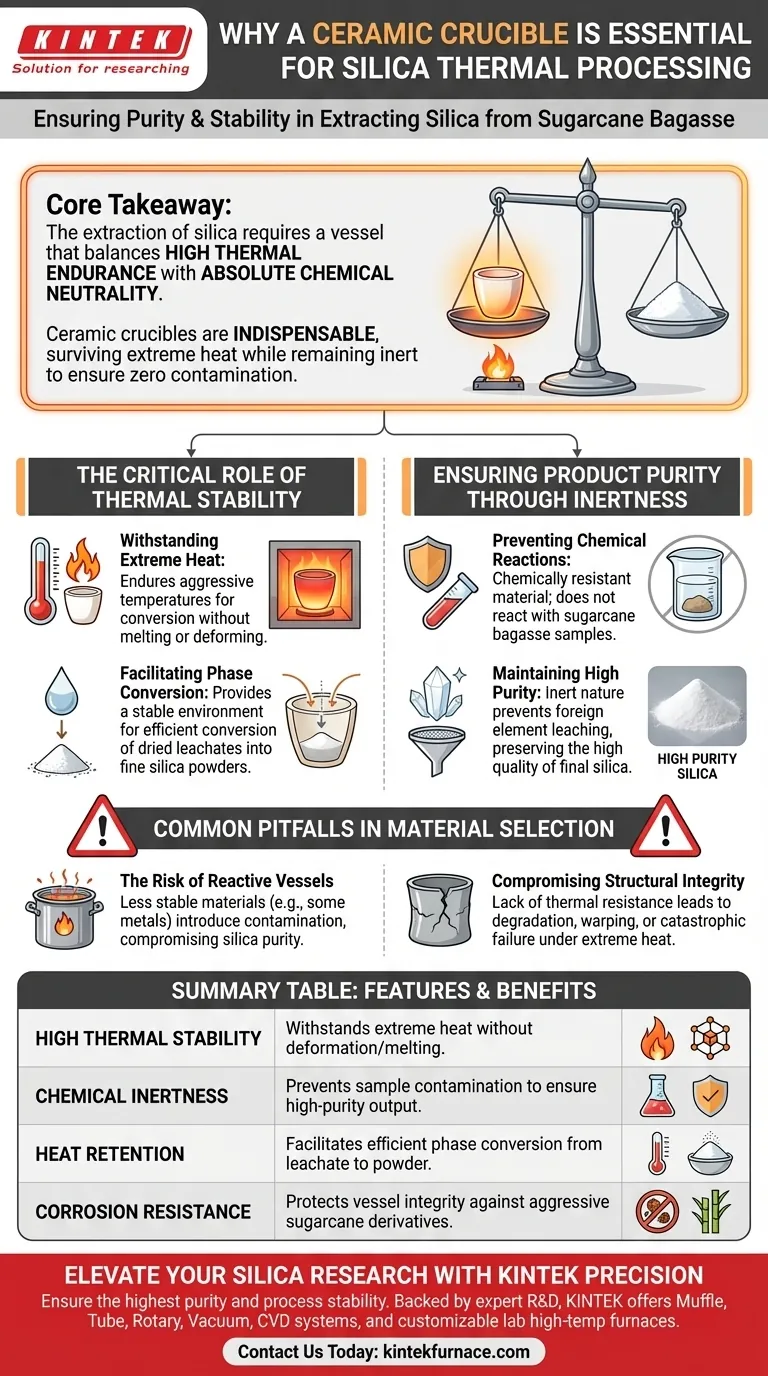

Core Takeaway The extraction of silica from sugarcane bagasse requires a containment vessel that balances high thermal endurance with absolute chemical neutrality. Ceramic crucibles are indispensable because they survive the extreme heat required for processing while remaining inert, ensuring the final silica product is not contaminated by the vessel itself.

The Critical Role of Thermal Stability

Withstanding Extreme Heat

The thermal processing of sugarcane bagasse derivatives requires aggressive heating to convert materials into the desired state. Ceramic crucibles offer exceptional thermal stability, allowing them to endure these high temperatures without melting or deforming.

Facilitating Phase Conversion

The process specifically aims to convert dried leachates into fine powders. This physical transformation demands a stable environment that can hold heat consistently, which the ceramic structure provides efficiently.

Ensuring Product Purity Through Inertness

Preventing Chemical Reactions

In many extraction processes, the vessel can inadvertently become a reactant. A ceramic crucible is chemically resistant, meaning it will not react with the sugarcane bagasse sample during processing.

Maintaining High Purity

The ultimate goal of this extraction is to obtain pure silica. The inert nature of ceramic is critical for this objective, as it ensures that no foreign elements from the container leach into the sample, thereby preserving the high purity of the final silica product.

Common Pitfalls in Material Selection

The Risk of Reactive Vessels

Choosing a vessel made from less stable materials, such as certain metals, introduces a high risk of chemical contamination. If the vessel reacts with the leachate at high temperatures, the purity of the silica is immediately compromised.

Compromising Structural Integrity

Vessels that lack the specific thermal resistance of ceramic may degrade or warp under the extreme heat required for this specific conversion. This can lead to sample loss or catastrophic failure of the containment during the thermal treatment phase.

Making the Right Choice for Your Goal

When setting up a thermal processing workflow for silica extraction, your choice of crucible dictates the quality of your output.

- If your primary focus is Product Purity: Select a high-grade ceramic crucible to ensure total chemical inertness and prevent sample contamination.

- If your primary focus is Process Stability: Rely on ceramic materials to withstand the specific high-temperature requirements needed to convert leachates to fine powder without structural failure.

The use of a ceramic crucible is not just a preference; it is a fundamental requirement for achieving a contaminant-free, high-quality silica product.

Summary Table:

| Feature | Benefit to Silica Extraction |

|---|---|

| High Thermal Stability | Withstands extreme heat without deformation or melting |

| Chemical Inertness | Prevents sample contamination to ensure high-purity output |

| Heat Retention | Facilitates efficient phase conversion from leachate to powder |

| Corrosion Resistance | Protects vessel integrity against aggressive sugarcane derivatives |

Elevate Your Silica Research with KINTEK Precision

Ensure the highest purity and process stability for your material extraction. Backed by expert R&D and world-class manufacturing, KINTEK offers a comprehensive range of Muffle, Tube, Rotary, Vacuum, and CVD systems, along with specialized lab high-temp furnaces—all customizable to meet your unique thermal processing needs.

Ready to optimize your workflow with reliable, high-performance equipment? Contact us today to discuss your project requirements!

Visual Guide

References

- Green Synthesis of Silica Nanoparticles from Sugarcane Bagasse Ash for Sustainable Heavy Metal Remediation from Industrial Effluents. DOI: 10.62154/ajastr.2025.019.01017

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Laboratory Muffle Oven Furnace with Bottom Lifting

- Electric Rotary Kiln Pyrolysis Furnace Plant Machine Small Rotary Kiln Calciner

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

- Laboratory Vacuum Tilt Rotary Tube Furnace Rotating Tube Furnace

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

People Also Ask

- Why Use Vacuum-Sealed Quartz Tubes for CVT CIPS Synthesis? Ensuring Purity and Precision

- Why are high-purity alumina crucibles utilized for CsV3Sb5 crystal growth? Ensure Purity in Self-Flux Synthesis

- What are the benefits of the improved circulating water vacuum pump? Save Costs and Go Green in Your Lab

- Why are laboratory heating and stirring devices necessary for Pechini and sol-gel synthesis? Ensure Precise Homogeneity

- Why are magnesium oxide-stabilized zirconia crucibles used for melting alloys? High-Temp Stability up to 1900°C

- Why is a vacuum drying oven essential for Pd-Ni/ZrO2 catalyst preparation? Ensure Uniform Metal Distribution

- What is the function of a high-purity Argon (Ar) gas flow control system? Ensure Superior Nanowire Uniformity

- What role do quartz tubes play in semiconductor manufacturing? Essential for Purity and High-Temp Processes