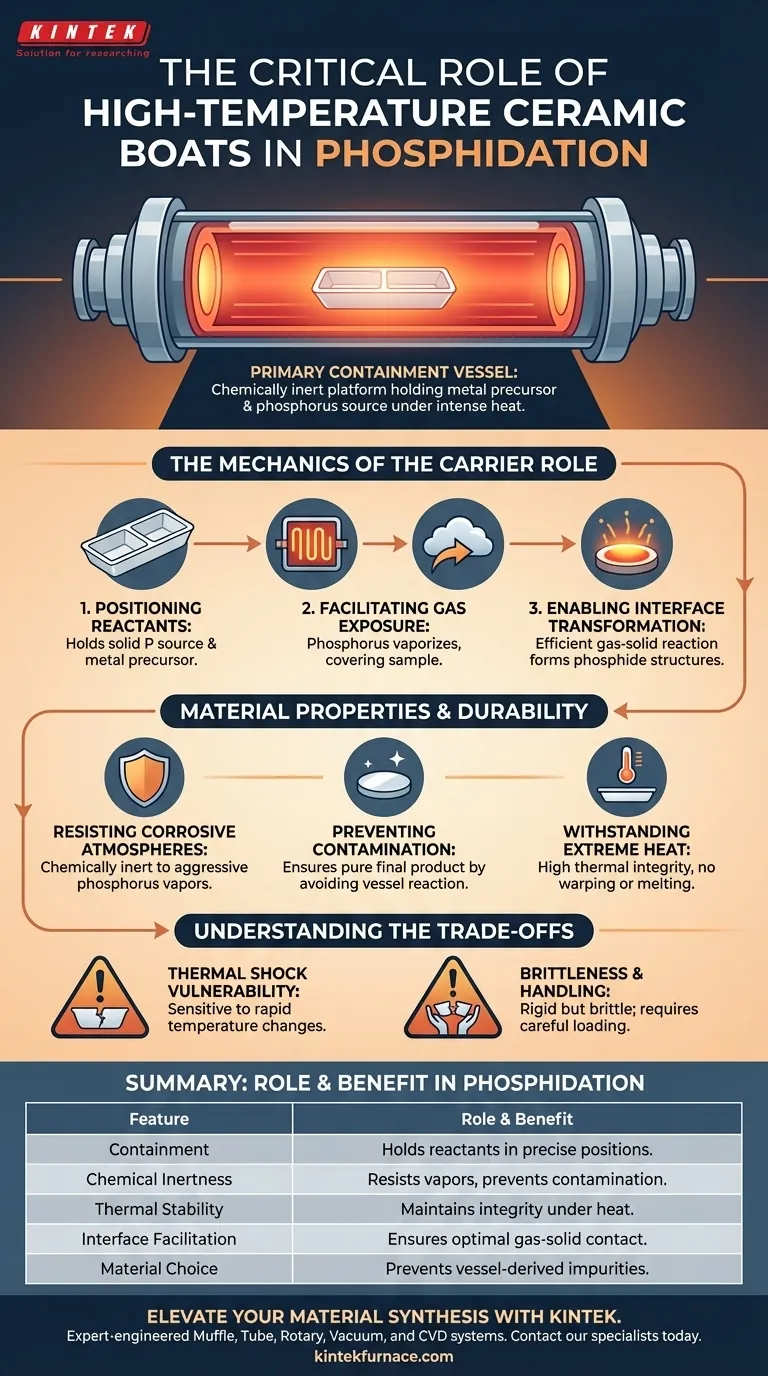

The high-temperature ceramic boat functions as the primary containment vessel for both the metal precursor and the phosphorus source during the phosphidation process. It serves as a chemically inert platform that holds these materials within the furnace, ensuring they remain stable while subjecting them to the intense thermal environment required for reaction.

The ceramic boat acts as a stable, non-reactive stage for chemical transformation. By withstanding corrosive phosphorus vapors and high heat, it allows for the precise, pure transformation of metal precursors without introducing contaminants from the vessel itself.

The Mechanics of the Carrier Role

Positioning the Reactants

In a laboratory furnace, the specific placement of materials is critical. The ceramic boat serves as a carrier, holding the solid phosphorus source and the metal precursor samples in fixed positions.

Facilitating Gas Exposure

As the furnace heats up, the phosphorus source vaporizes. The boat is designed to ensure that the released phosphorus gas covers the sample surfaces accurately.

Enabling Interface Transformation

This targeted exposure is what drives the reaction. The boat facilitates a heterogeneous interface transformation, allowing the gas to react efficiently with the solid metal to form the desired phosphide structures.

Material Properties and Durability

Resisting Corrosive Atmospheres

Phosphidation creates a highly aggressive chemical environment. The ceramic material provides chemical inertness, meaning it will not react with the corrosive phosphorus gas.

Preventing Contamination

If the boat were to react with the gas, it would degrade and release impurities into your sample. The inert nature of the ceramic ensures the final product remains pure.

Withstanding Extreme Heat

The process requires high temperatures to activate the reaction. The boat possesses high thermal stability, allowing it to maintain its structural integrity without warping or melting during the heating cycle.

Understanding the Trade-offs

Thermal Shock Vulnerability

While thermally stable, ceramics can be sensitive to rapid temperature changes. Heating or cooling the furnace too aggressively can cause the boat to crack due to thermal shock.

Brittleness and Handling

Ceramic boats are mechanically rigid but brittle. They require careful handling during loading and unloading, as physical impact can easily shatter the vessel, potentially ruining the experiment and contaminating the furnace tube.

Making the Right Choice for Your Experiment

To ensure the success of your phosphidation process, consider how you utilize the ceramic boat based on your specific experimental goals:

- If your primary focus is Sample Purity: Ensure the ceramic boat is thoroughly cleaned and inspect it for micro-cracks before use to prevent any cross-contamination or reaction with the vessel itself.

- If your primary focus is Reaction Efficiency: Place the phosphorus source and metal precursor within the boat at a distance that optimizes the flow of vapor over the sample surface.

By selecting the correct vessel, you ensure that the only chemistry happening in your furnace is the one you intended.

Summary Table:

| Feature | Role & Benefit in Phosphidation |

|---|---|

| Containment | Holds solid reactants (P source and metal) in precise positions. |

| Chemical Inertness | Resists corrosive phosphorus vapors to prevent sample contamination. |

| Thermal Stability | Maintains structural integrity under extreme heating cycles. |

| Interface Facilitation | Ensures optimal gas-solid contact for efficient surface reaction. |

| Material Choice | Essential for preventing vessel-derived impurities in the final product. |

Elevate Your Material Synthesis with KINTEK

Precision in phosphidation requires more than just high temperatures—it demands reliable, high-performance equipment. KINTEK provides expert-engineered solutions, including Muffle, Tube, Rotary, Vacuum, and CVD systems, all fully customizable to meet your specific laboratory requirements.

Backed by industry-leading R&D and manufacturing, our furnaces ensure the thermal stability and atmospheric control necessary for sensitive chemical transformations. Don't compromise on purity or efficiency. Contact our specialists today to find the perfect high-temperature furnace solution for your research.

Visual Guide

References

- Yu Gao, Xiaoteng Liu. In situ growth of three-dimensional walnut-like nanostructures of W-Ni2P@NiFe LDH/NF as efficient bifunctional electrocatalysts for water decomposition. DOI: 10.1007/s42114-024-01176-y

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

People Also Ask

- Why are vacuum-sealed quartz tubes required for SnSe melting? Ensure Purity & Stoichiometry

- What is a circulating water vacuum pump also known as? Discover Its Role in Lab Efficiency

- Why is a high vacuum pumping system required for Bi2Se3-Nd2Se3 alloying? Ensure Purity in Rare Earth Synthesis

- What are the preparation steps for a water circulating vacuum pump? Ensure Optimal Performance and Longevity

- Which industries can benefit from using the circulating water multifunctional vacuum pump? Discover Clean, Efficient Vacuum Solutions

- What is the role of specialized sealing ferrules in heating experiments? Ensure Hermetic Isolation and Purity

- Why are high-purity alumina crucibles used for LLZO sintering? Master Lithium Volatility Control

- Why is a mechanical vacuum pump essential for Ti-50Nb-xMo melting? Ensure Purity & Prevent Alloy Embrittlement